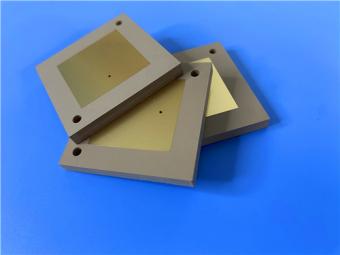

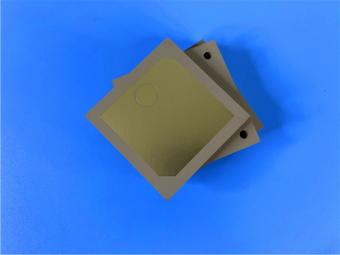

16-layer S1000-2M TG180 FR-4 Material 3oz Heavy Copper PCB With HASL LF

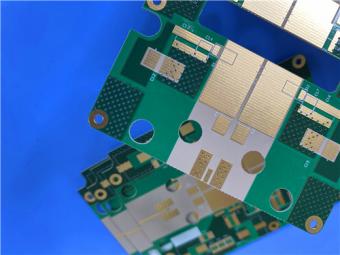

This 16-layer Printed Circuit Board engineered for mission-critical applications requiring exceptional current-handling capacity, robust thermal management, and unwavering structural integrity in harsh operating environments. Fabricated on the high-performance S1000-2M TG180 substrate and featuring a uniform 3oz (105µm) copper weight on all layers, this board represents the pinnacle of power distribution and dense interconnection design.

Designed to exceed the demands of next-generation computing, high-power communication infrastructure, and ruggedized automotive systems, this PCB integrates the durability of heavy copper with the dimensional stability ofadvanced FR-4 materials. Its construction ensures reliable operation under sustained thermal load and mechanical stress, making it perfectly suited for lead-free assembly processes and long-lifecycle products.

PCB Construction

The following table summarizes the core physical and manufacturing parameters that define the board's construction and quality assurance standards.

|

Parameter

|

Specification

|

|

Base Material

|

S1000-2M TG180

|

|

Layer Count

|

16 layers

|

|

Board Dimensions

|

72mm × 93mm per PCS, tolerance ±0.15mm

|

|

Minimum Trace/Space

|

4/6 mils

|

|

Minimum Hole Size

|

0.3mm

|

|

Blind/Buried Vias

|

No blind vias

|

|

Finished Board Thickness

|

6.7mm

|

|

Finished Copper Weight

|

3oz per layer (all layers)

|

|

Via Plating Thickness

|

20 μm

|

|

Surface Finish

|

Lead-Free HASL (HASL LF)

|

|

Top Silkscreen

|

White

|

|

Bottom Silkscreen

|

White

|

|

Top Solder Mask

|

Green

|

|

Bottom Solder Mask

|

Green

|

|

Electrical Test

|

100% electrical test prior to shipment

|

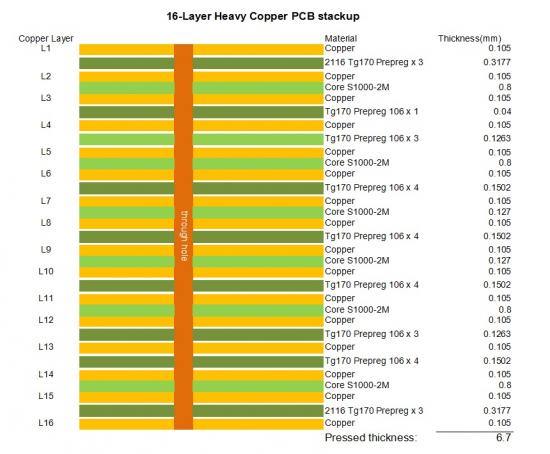

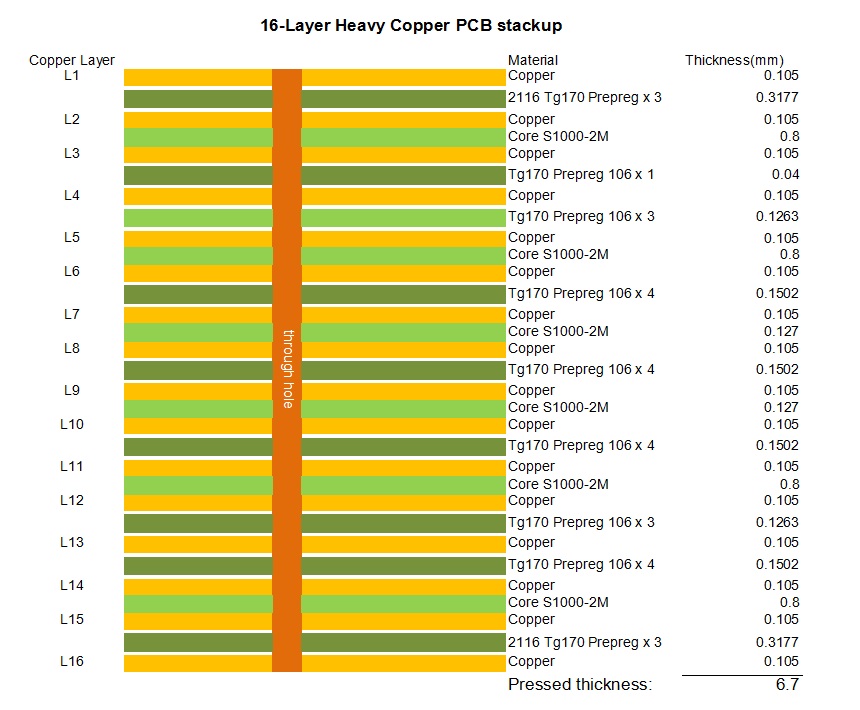

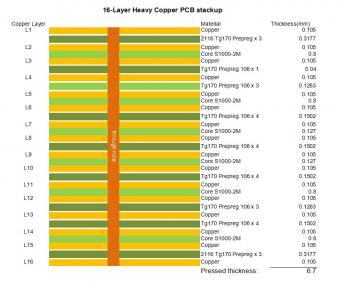

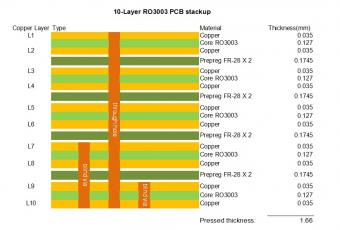

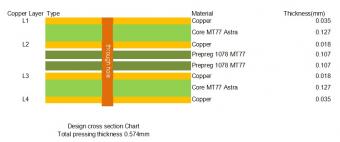

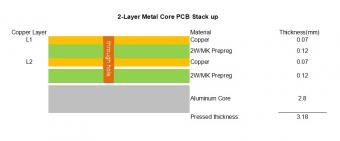

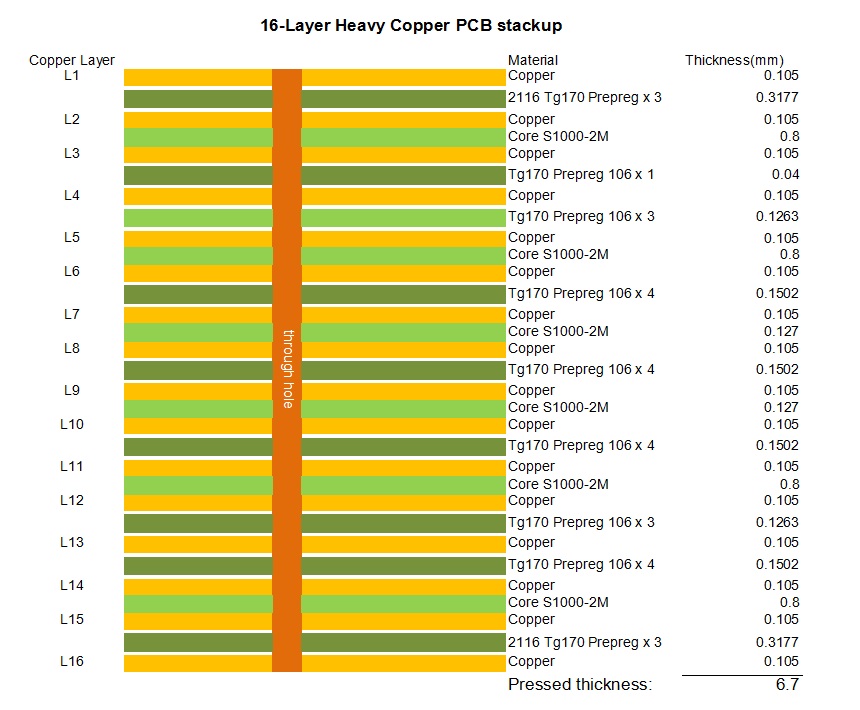

16-Layer Heavy Copper PCB Stackup

The stackup is engineered for optimal signal integrity, power plane decoupling, and mechanical symmetry to prevent warpage. The uniform3oz copper cladding is a defining feature across all conductive layers.

Core Material: S1000-2M TG180 High-Performance Laminate

The foundation of this PCB is the Shengyi S1000-2M material, a multi-functional epoxy resin system reinforced with glass fabric. This material is specifically formulated for high-layer-count and high-reliability applications.

Key Features of S1000-2M Material:

-

Superior Thermo-Mechanical Reliability: Its lower Z-axis Coefficient of Thermal Expansion (CTE) minimizes stress on plated through-holes during thermal cycling, ensuring excellent through-hole reliability and preventing barrel cracking.

-

Exceptional Environmental Resistance: Demonstrates excellent Pressure Cooker Test (PCT) performance and low water absorption, leading to high resistance to heat, humidity, and long-term exposure to harsh conditions.

-

Enhanced Processibility & Lead-Free Compatibility: Offers excellent mechanical processibility (drilling, routing) and high thermal resistance, making it fully compatible with demanding lead-free (RoHS) assembly processes that involve higher reflow temperatures.

S1000-2M Data Sheet

|

Test Items

|

Test Method

|

Test Condition

|

Unit

|

Typical Value

|

|

Tg

|

IPC-TM-650 2.4.24.4

|

DMA

|

℃

|

185

|

|

IPC-TM-650 2.4.25D

|

DSC

|

℃

|

180

|

|

|

Td

|

IPC-TM-650 2.4.24.6

|

TGA (5% W.L)

|

℃

|

355

|

|

T260

|

IPC-TM-650 2.4.24.1

|

TMA

|

min

|

>60

|

|

T288

|

IPC-TM-650 2.4.24.1

|

TMA

|

min

|

30

|

|

T300

|

IPC-TM-650 2.4.24.1

|

TMA

|

min

|

15

|

|

Thermal Stress

|

IPC-TM-650 2.4.13.1

|

288℃, solder dip

|

s

|

>100

|

|

CTE (Z-axis)

|

IPC-TM-650 2.4.24

|

Before Tg

|

ppm/℃

|

41

|

|

IPC-TM-650 2.4.24

|

After Tg

|

ppm/℃

|

208

|

|

|

IPC-TM-650 2.4.24

|

50-260℃

|

%

|

2.4

|

|

|

Permittivity (1GHz)

|

IPC-TM-650 2.5.5.9

|

C-24/23/50

|

-

|

4.6

|

|

Loss Tangent (1GHz)

|

IPC-TM-650 2.5.5.9

|

C-24/23/50

|

-

|

0.018

|

|

Volume Resistivity

|

IPC-TM-650 2.5.17.1

|

C-96/35/90

|

MΩ-cm

|

8.7×108

|

|

Surface Resistivity

|

IPC-TM-650 2.5.17.1

|

C-96/35/90

|

MΩ

|

2.2×107

|

|

Arc Resistance

|

IPC-TM-650 2.5.1

|

D-48/50+D-0.5/23

|

s

|

133

|

|

Dielectric Breakdown

|

IPC-TM-650 2.5.6

|

D-48/50+D-0.5/23

|

kV

|

>45

|

|

Peel Strength (1oz)

|

IPC-TM-650 2.4.8

|

288℃/10s

|

N/mm [lb/in]

|

1.3 [7.43]

|

|

Flexural Strength (LW/CW)

|

IPC-TM-650 2.4.4

|

A

|

Mpa

|

567/442

|

|

Water Absorption

|

IPC-TM-650 2.6.2.1

|

D-24/23

|

%

|

0.08

|

|

Flammability

|

UL94

|

C-48/23/50

|

Rating

|

V-0

|

|

CTI

|

IEC60112

|

A

|

Rating

|

PLC 3

|

Typical Applications for S1000-2M

This material is the substrate of choice for high-layer-count PCBs where reliability is non-negotiable. It is widely deployed in:

-

Computing: High-end servers, routers, and data storage systems.

-

Communication: Base station power amplifiers, network switching backplanes.

-

Automotive Electronics: Under-the-hood control units, power inverters for EVs, and ADAS systems.

-

Industrial & Power Electronics: Motor drives, UPS systems, and power converters.

The Advantage of Heavy Copper Construction

What is Heavy Copper?

Traditionally, PCBs use 1oz (35µm) or 2oz (70µm) copper. Heavy Copper technically refers to copper weights of 3oz (105µm) and above per square foot. This board utilizes a significant 3oz weight on every layer.

Functions and Benefits:

1) High Current Carrying Capacity: The primary function. Cross-sectional area increases linearly with copper weight, drastically reducing trace resistance. This allows the board to conduct tens or hundreds of amperes without overheating or excessive voltage drop.

2) Enhanced Thermal Management: The thick copper layers act as an embedded heat spreader, conducting heat away from hot components (like MOSFETs, regulators) and distributing it across the board, reducing hotspot temperatures and improving system reliability.

3) Increased Mechanical Strength: Heavy copper adds structural rigidity to the PCB, particularly at connector points and in through-hole pads, increasing durability in high-vibration environments.

4) Space Efficiency: Instead of using wide, thin traces or external bus bars for high-power paths, heavy copper allows for more compact, efficient routing of power traces, saving valuable board space.

Application Domains for Heavy Copper PCBs:

-

Power Conversion & Distribution

-

Automotive & Electric Vehicles

-

Renewable Energy

-

Industrial Equipment

-

Aerospace & Defense

Conclusion

The 16-layer Heavy Copper PCB is not a standard circuit board; it is a robust electromechanical platform. By marrying the exceptional stability and reliability of S1000-2M TG180 material with the formidable current and thermal performance of all-layer 3oz heavy copper, this product is engineered to empower the most demanding power-dense and reliability-critical electronic systems on the market today.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com