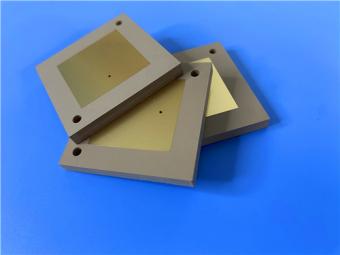

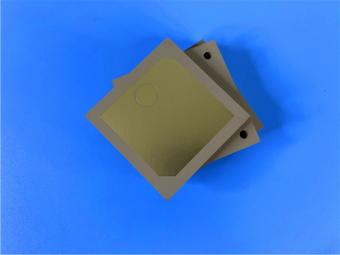

2-Layer Aluminum Metal Core 2W/MK AL 5052 PCB HASL Surface 2oz Copper

In the relentless pursuit of miniaturization and increased power density in modern electronics, effective thermal management has transitioned from a secondary consideration to a primary design criterion. Conventional FR-4 PCBs often reach their thermal limits, leading to premature component failure, reduced efficiency, and compromised system reliability. To address this critical challenge, we present our advanced 2-Layer Aluminum Core Printed Circuit Board (MCPCB), engineered not just to conduct electricity, but to masterfully manage heat. This product is the culmination of precise material science and stringent manufacturing controls, offering a robust, data-driven thermal management solution for the most demanding applications.

Product Overview & Core Specifications

This 2W/MK Aluminum PCB is a purpose-built,double-sided metal-clad board designed where heat dissipation is paramount. It transcends the role of a simple electrical interconnect to become an integral, active component of your thermal management system. The foundation of its performance lies in its meticulously specified construction:

|

Category

|

Parameter

|

Specification

|

Tolerance

|

Remarks

|

|

General Specifications

|

Product Structure

|

Double-layer Copper Aluminum PCB

|

-

|

-

|

|

Finished PCB Thickness

|

3.2 mm

|

3.15-3.25 mm

|

Nominal value: 3.2 mm

|

|

|

Finished Copper Weight

|

2 oz

|

-

|

Corresponding to outer copper thickness 73 μm

|

|

|

PCB Dimension (Single Piece)

|

100 mm × 59 mm

|

-

|

-

|

|

|

Surface Finish

|

Lead-free Hot Air Solder Leveling (HASL)

|

-

|

-

|

|

|

Laminate & Substrate

|

Aluminum Alloy Model

|

AL 5052

|

-

|

-

|

|

Substrate Supplier

|

Mingtai

|

-

|

-

|

|

|

Thermal Conductivity

|

2 W/mK

|

-

|

-

|

|

|

Thickness of Dielectric (Prepreg)

|

120 μm

|

-

|

-

|

|

|

Plating Details

|

Plating Thickness of Hole Wall

|

22.25 μm

|

20.5-24 μm

|

Average value for reference

|

|

Outer Copper Thickness

|

73 μm

|

-

|

Matches 2 oz copper weight

|

|

|

Solder Mask (S/M)

|

S/M Material Type

|

Lanbang W-8

|

-

|

-

|

|

S/M Color

|

White

|

-

|

-

|

|

|

S/M Rigidity (Pencil Test)

|

5H

|

-

|

-

|

|

|

S/M Thickness

|

17 μm

|

16-18 μm

|

Average value for reference

|

|

|

S/M Location

|

Top Layer

|

-

|

Only applied on top layer

|

|

|

Component Marking

|

Marking Material Type

|

Lanbang Thermasetting-08

|

-

|

Thermosetting ink

|

|

Marking Color

|

Black

|

-

|

-

|

|

|

Marking Location

|

Top Layer

|

|

|

|

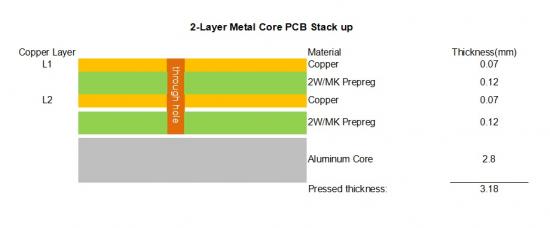

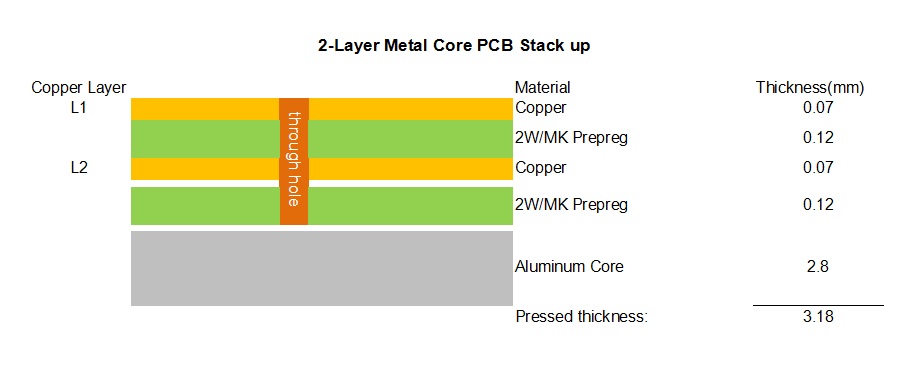

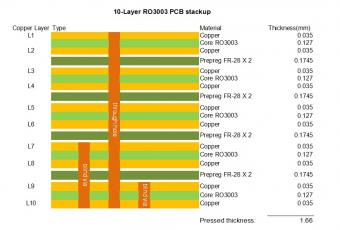

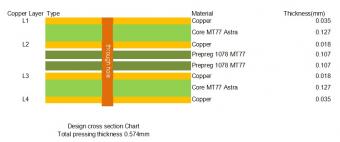

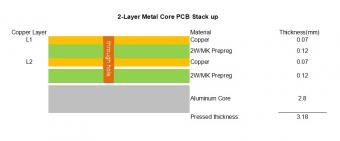

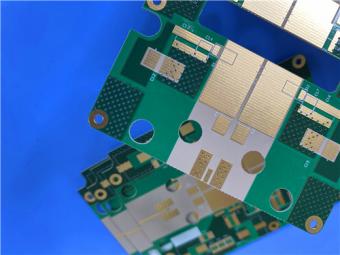

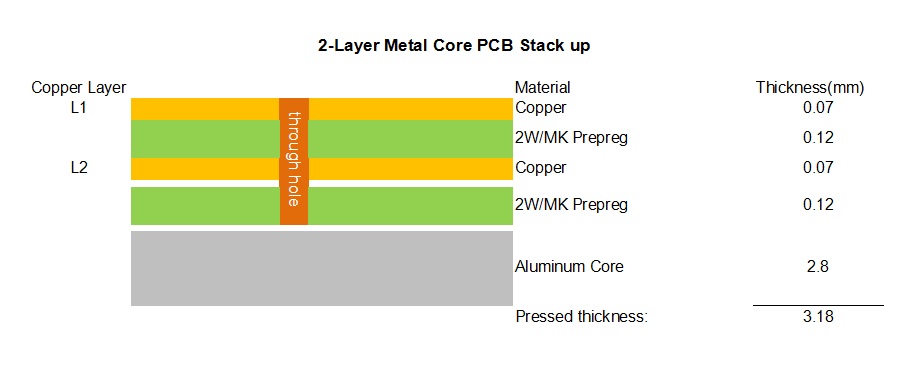

2-layer Metal Core PCB stackup:

Why Choose an Aluminum Core PCB?

The decision to migrate from standard substrates to an aluminum core is driven by physics and necessity. For applications such as high-power LED lighting (automotive headlights, street lighting, industrial lighting), power supplies and converters, motor controllers, and automotive electronics, the generated heat flux can degrade performance and lifespan. An aluminum substrate acts as a massive heatsink, integrated directly into the board structure. Its high thermal conductivity lowers the operating temperature of critical components like LEDs, MOSFETs, and ICs by 20-50% compared to FR-4 under identical loads. This directly translates to:

1) Enhanced Lifespan: Mitigating the primary cause of electronic failure—heat.

2) Increased Performance: Preventing thermal throttling in components, allowing them to operate at optimal efficiency.

3) Improved Reliability: Reducing thermal stress on solder joints and materials, minimizing failures.

4) Design Simplification: Potentially reducing the need for bulky external heatsinks, enabling more compact product designs.

The Key Technology: The Dielectric Layer (Prepreg)

The exceptional performance of an MCPCB hinges on a single, critical component: the dielectric insulating layer, or prepreg. This layer sits between the aluminum core and the copper circuitry, and it must perform two opposing functions perfectly: be an excellent electrical insulator while simultaneously being an exceptional thermal conductor.

This is the engineering challenge we have mastered. In this specific product, we employ a specialized, thermally conductive but electrically insulating prepreg with a precisely controlled thickness of 120µm (micrometers). This layer is filled with ceramic or other thermally conductive particles within a polymer matrix. The material formulation and the 120µm thickness are a calculated compromise:

-

Thermal Performance: A thinner dielectric layer reduces thermal resistance, allowing heat to transfer more efficiently from the copper traces (and thus the components) to the aluminum core. Our specified thickness optimizes this heat transfer path.

-

-

Electrical Integrity: The layer must withstand high potentials (typically 2kV to 4kV or more) to prevent short circuits. The 120µm thickness provides a robust and reliable electrical barrier, ensuring long-term insulation resistance.

-

-

Mechanical Adhesion: It must form an unbreakable bond between the copper foil and the aluminum plate, surviving thermal expansion cycles without delamination.

Our manufacturing process ensures this prepreg is laminated under high pressure and temperature, creating a homogeneous, void-free interface. This meticulous control over the dielectric layer is what transforms the aluminum plate from a mere structural base into a functional, high-performance thermal conduit.

Conclusion

This 2-Layer Aluminum Core PCB is more than a component; it is a thermal management system engineered onto a board. From the specified AL 5052 core and 2 W/m·K conductivity to the critical 120µm dielectric layer and the robust 2 oz copper/24µm hole plating, every parameter is defined and controlled to deliver measurable performance. It is the definitive choice for designers who prioritize reliability, longevity, and performance in high-power, heat-sensitive applications. By integrating this solution, you are not just building a circuit; you are building a foundation for product excellence.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com