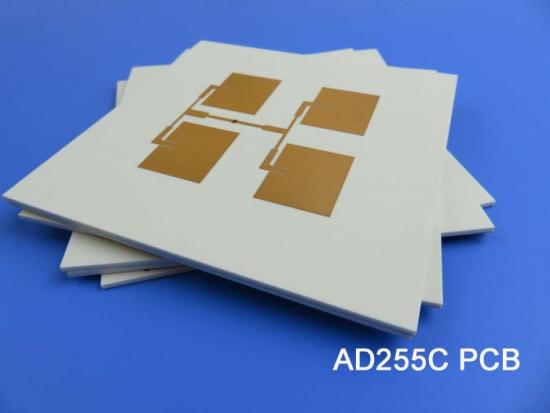

AD255C 60mil Rogers Material High Frequency PCB with Immersion Gold

Introduction

AD255C PCB is Rogers AD255C antenna grade laminate and the printed circuit boards (PCBs) that utilize this antenna material.

AD255C copper clad laminates combine a fluoropolymer resin system with selected ceramic materials and fiberglass reinforcement. This unique combination offers lower loss, lower thermal expansion, and lower passive intermodulation (PIM), making it suitable for a wide range of microwave and radio frequency applications in telecommunications infrastructure.

Micro-dispersed ceramics are incorporated into AD255C to improve its thermal stability by reducing its coefficient of thermal expansion (CTE) and enhancing phase stability at different temperatures.

Now, let's examine the data sheet to learn more about the properties of AD255C.

AD255C Typical Properties

One of the most remarkable features of AD255C Rogers Printed Circuit Board is its PIM rating of -159/-163 dBc. This rating is achieved using reverse treated ED copper foil, with typical values of -159 dBc at a thickness of 30mil and -163 dBc at a thickness of 60mil. These values were obtained through extensive PIM testing at Rogers, using a swept tone, reflected method on a 50Ω microstrip test vehicle at 1900 MHz.

Rogers AD255C PCB has a dielectric constant of 2.55 (process) and 2.60 (design), enabling excellent signal transmission at high frequencies.

More typical properties as follow:

|

Properties

|

AD255C

|

Units

|

Test Conditions

|

Test Method

|

|

Electrical Properties

|

|

PIM (30mil/60mil)

|

-159/-163

|

dBc

|

Reflected 43 dBm swept tones at 1900 MHz, S1/S1

|

Rogers Internal 50 ohm

|

|

Dielectric Constant (process)

|

2.55

|

-

|

23°C @ 50% RH

|

10 GHz

|

IPC TM-650 2.5.5.5

(IPC TM-650 2.5.5.3)

|

|

Dielectric Constant (design)

|

2.60

|

-

|

C-24/23/50

|

10 GHz

|

Microstrip Differential Phase Length

|

|

Dissipation Factor (process)

|

0.0013

|

-

|

23°C @ 50% RH

|

10 GHz

|

IPC TM-650 2.5.5.5

|

|

Electrical Strength (dielectric strength)

|

911

|

V/mil

|

-

|

-

|

IPC TM-650 2.5.6.2

|

|

Thermal Coefficient of Dielectric Constant

|

-110

|

ppm/ºC

|

0°C to 100°C

|

10 GHz

|

IPC TM-650 2.5.5.5

|

|

Volume Resistivity

|

7.4 x 108

|

Mohm-cm

|

C-96/35/90

|

-

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity

|

3.6 x 107

|

Mohm

|

C-96/35/90

|

-

|

IPC TM-650 2.5.17.1

|

|

Dielectric Breakdown

|

>40

|

kV

|

D-48/50

|

X/Y direction

|

IPC TM-650 2.5.6

|

|

Thermal Properties

|

|

Decomposition Temperature (Td)

|

>500

|

˚C

|

2hrs @ 105˚C

|

5% Weight Loss

|

IPC TM-650 2.3.40

|

|

Thermal Conductivity

|

0.35

|

W/mK

|

-

|

z direction

|

ASTM D5470

|

|

Coefficient of Thermal Expansion - x

|

34

|

ppm/˚C

|

-

|

-55˚C to 288˚C

|

IPC TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - y

|

26

|

ppm/˚C

|

-

|

-55˚C to 288˚C

|

IPC TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - z

|

196

|

ppm/˚C

|

-

|

-55˚C to 288˚C

|

IPC TM-650 2.4.41

|

|

Time to Delamination

|

>60

|

minutes

|

as-received

|

288˚C

|

IPC TM-650 2.4.24.1

|

|

Mechanical Properties

|

|

Copper Peel Strength after Thermal Stress

|

2.4

(13.6)

|

N/mm (lbs/in)

|

10s @288˚C

|

35 μm foil

|

IPC TM-650 2.4.8

|

|

Flexural Strength (MD/CMD)

|

8.8/6.4 (60.7/44.1)

|

MPa (ksi )

|

25°C ± 3°C

|

-

|

ASTM D790

|

|

Tensile Strength (MD/CMD)

|

8.1/6.6 (55.8/45.5)

|

MPa (ksi )

|

23°C/50% RH

|

-

|

ASTM D3039/D3039-14

|

|

Flex Modulus (MD/CMD)

|

930/818 (6,412/5,640)

|

MPa (ksi )

|

25°C ± 3°C

|

-

|

IPC-TM-650 Test Method 2.4.4

|

|

Dimensional Stability (MD/CMD)

|

0.03/0.07

|

mils/inch

|

after etch + bake

|

-

|

IPC-TM-650 2.4.39a

|

|

Physical Properties

|

|

Flammability

|

V-0

|

-

|

-

|

-

|

UL-94

|

|

Moisture Absorption

|

0.03

|

%

|

E1/105 +D48/50

|

-

|

IPC TM-650 2.6.2.1

|

|

Density

|

2.28

|

g/cm3

|

C-24/23/50

|

-

|

ASTM D792

|

|

Specific Heat Capacity

|

0.813

|

J/g°K

|

2 hours at 105°C

|

-

|

ASTM E2716

|

AD255CPCB Capability

|

PCB material:

|

Glass-reinforced, PTFE based Composites

|

|

Designation:

|

AD255C

|

|

Dielectric constant:

|

2.55 (10 GHz)

|

|

Dissipation Factor

|

0.0013 (10 GHz)

|

|

Layer count:

|

Double Sided PCB, Multi-layer PCB, Hybrid PCB

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness:

|

20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 60mil (1.524mm), 125mil (3.175mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red, Purple etc.

|

|

Surface Finish:

|

Immersion gold, Hot air soldering level (HASL), Immersion silver, Immersion tin, OSP, Pure gold plated, ENEPIG, Bare copper, etc..

|

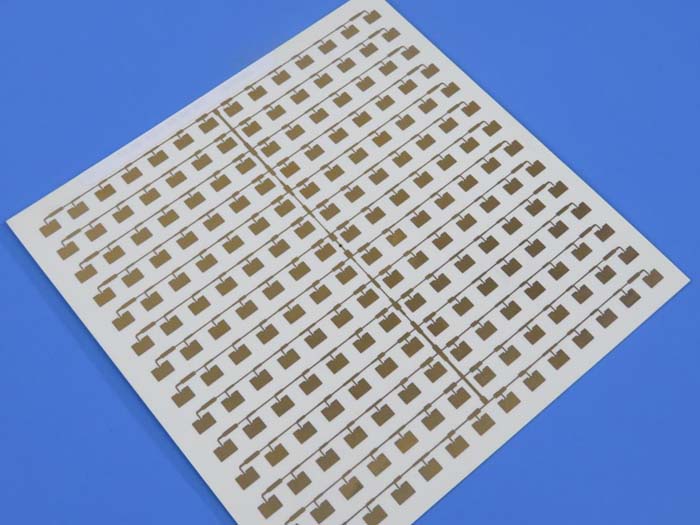

A Piece of AD255C PCB

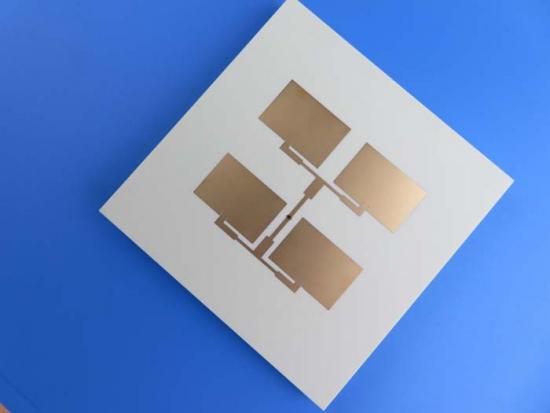

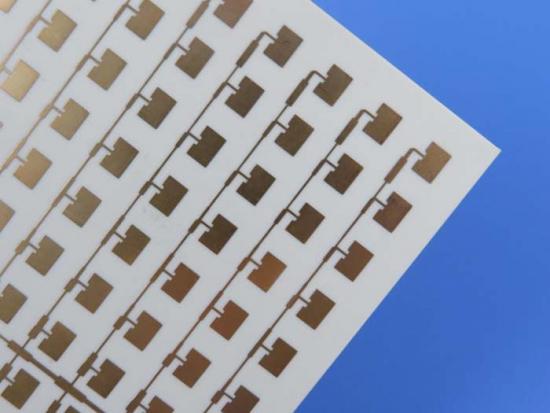

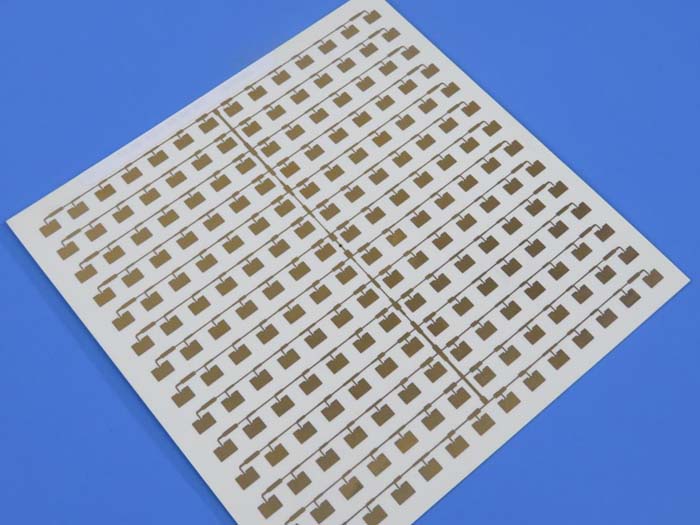

There is a 60mil AD255C PCB with immersion gold coating, specifically designed for automotive telematics antenna systems.

These PCBs also excel in cellular infrastructure base station antennas, commercial satellite radio antennas, and more.

Conclusion

AD255C high frequency PCBs can be processed using standard equipment and chemical processes for plating, imaging, and etching circuit patterns. It is important to preserve the post-etch laminate surface, as the remaining topography promotes improved adhesion to solder masks.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com