High

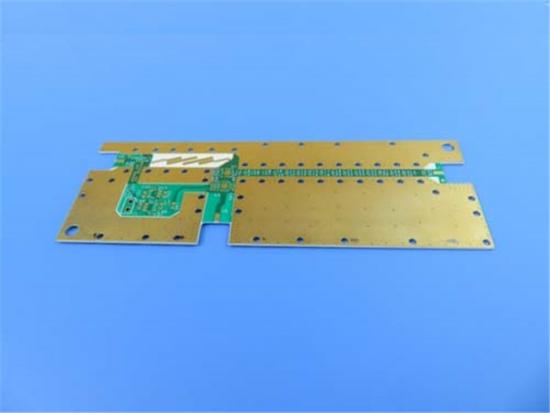

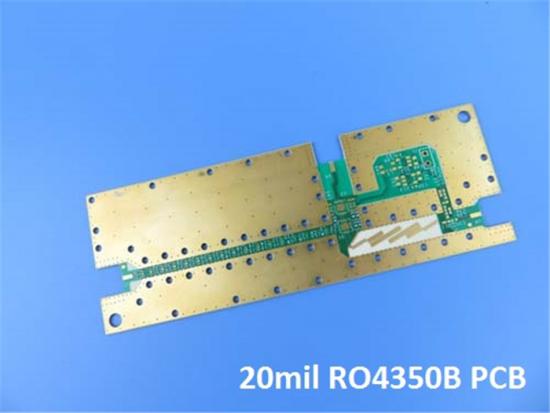

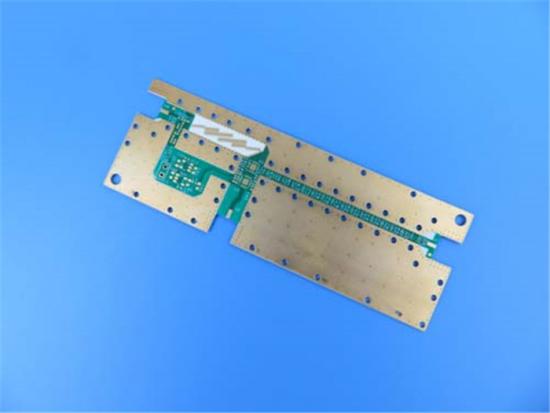

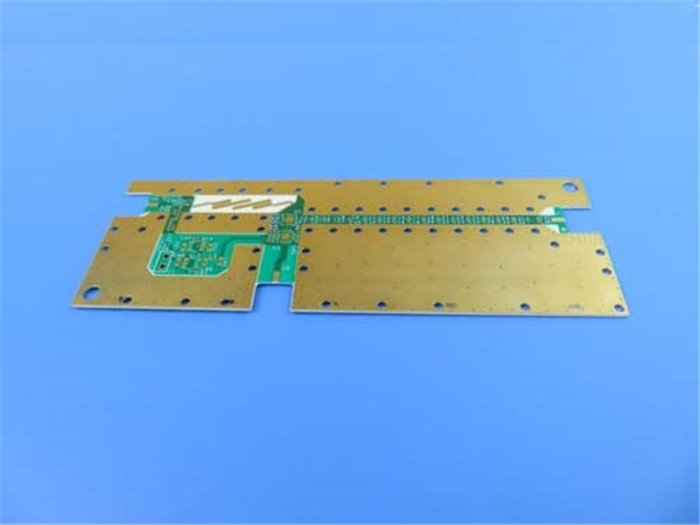

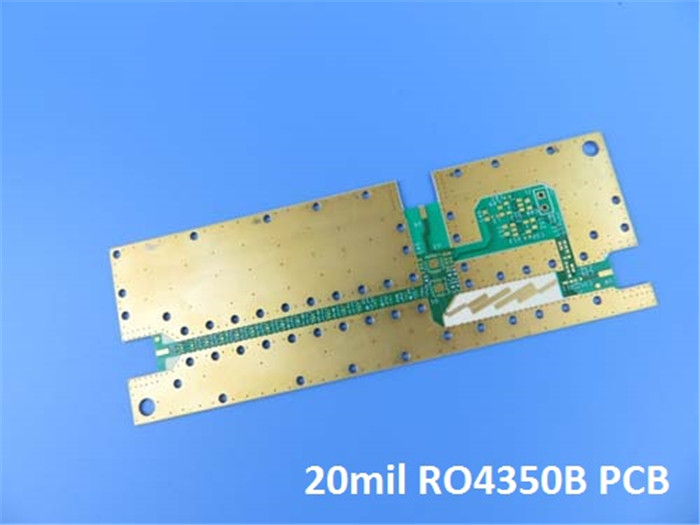

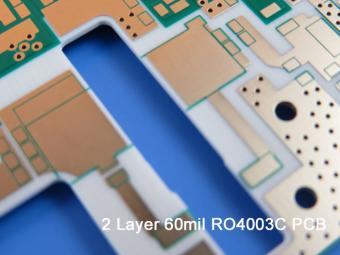

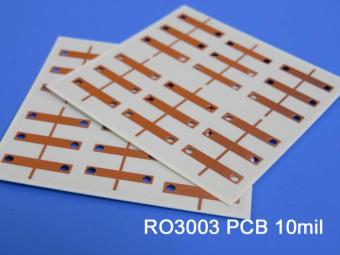

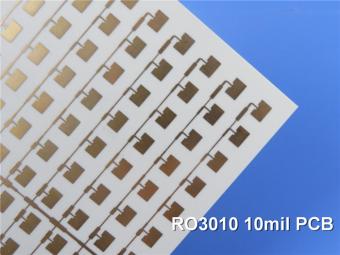

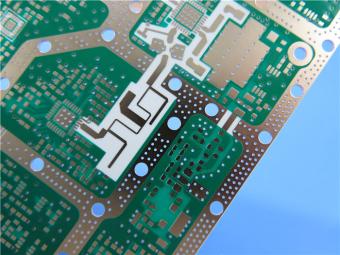

Frequency PCB Rogers 20mil 0.508mm RO4350B Double Sided RF PCB for Splitter

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

The

glass fiber reinforced (non-PTFE) hydrocarbon/ceramic laminates used in Rogers

Ro4350B high-frequency materials are intended for high volume, high-performance

commercial applications. Ro4350b are made to deliver exceptional RF performance

and affordable circuit manufacture. The end result is a low-loss material that

can be made at reasonable cost utilizing common epoxy/glass (FR4) techniques.

As operating frequencies rise to 500 MHz or more, a significant decrease in the

range of laminates that are typically accessible to designers occurs.

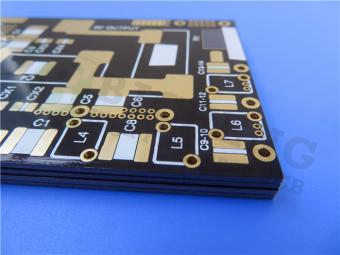

The

properties of the RO4350B PCB make it possible to create filters, coupling

networks, and impedance-controlled transmission lines in a repeatable manner.

The RO4350B series material can be used in many applications where traditional

printed circuit board laminates cannot be used due to higher operating

frequencies because of its low dielectric loss. The dielectric constant has one

of the lowest temperature coefficients of all printed circuits and is stable

across a large frequency range. It is the perfect substrate for broadband

applications because of this.

For

the creation of mixed dielectric multilayer PCB boards, it is a property

required. Even in extreme thermal shock applications, the low CTE of RO4350

laminates on the Z-axis ensures dependable through hole quality. The RO4350

series' material has a TG of more than 280 ° C (536 ° F), which ensures that

its expansion properties are steady at all circuit's process temperatures.

Printed circuit boards made from RO4350 Series laminates can be created quickly

and easily utilizing common FR4 circuit board manufacturing methods. The RO4350

series laminates do not require specialized preparatory procedures such sodium

etching, in contrast to high-performance PTFE-based materials. This material

can be handled by automated handling systems and washers to create the copper

surface. It is a robust, heat-stable laminate..

The

current selection of 1080 and 1674 glass fabric variants for RO4350B laminates

all adhere to the same standards for laminated electrical performance. RO4350

laminates feature RoHS compliant flame retardant technology for applications

requiring UL 94V-0 certification and are specifically made for direct

replacement of RO4350B material. These products satisfy IPC-4103/10 single

sheets for RO4003C and/11 for RO4350B specifications.

PCB

Specifications:

|

RO4350B

Typical Value

|

|

Property

|

RO4350B

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric

Constant,εProcess

|

3.48±0.05

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5 Clamped Stripline

|

|

Dielectric Constant,εDesign

|

3.66

|

Z

|

|

8 to 40 GHz

|

Differential

Phase Length Method

|

|

Dissipation Factortan,δ

|

0.0037

0.0031

|

Z

|

|

10

GHz/23℃

2.5 GHz/23℃

|

IPC-TM-650

2.5.5.5

|

|

Thermal Coefficient of ε

|

+50

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650

2.5.5.5

|

|

Volume Resistivity

|

1.2 x 1010

|

|

MΩ.cm

|

COND A

|

IPC-TM-650

2.5.17.1

|

|

Surface Resistivity

|

5.7 x109

|

|

MΩ

|

COND A

|

IPC-TM-650

2.5.17.1

|

|

Electrical Strength

|

31.2(780)

|

Z

|

Kv/mm(v/mil)

|

0.51mm(0.020")

|

IPC-TM-650

2.5.6.2

|

|

Tensile Modulus

|

16,767(2,432)

14,153(2,053)

|

X

Y

|

MPa(ksi)

|

RT

|

ASTM

D 638

|

|

Tensile Strength

|

203(29.5)

130(18.9)

|

X

Y

|

MPa(ksi)

|

RT

|

ASTM

D 638

|

|

Flexural Strength

|

255

(37)

|

|

MPa

(kpsi)

|

|

IPC-TM-650

2.4.4

|

|

Dimensional Stability

|

<0.5

|

X,Y

|

mm/m

(mil/inch)

|

after etch+E2/150℃

|

IPC-TM-650

2.4.39A

|

|

Coefficient of Thermal Expansion

|

10

12

32

|

X

Y

Z

|

ppm/℃

|

-55℃to288℃

|

IPC-TM-650

2.4.41

|

|

Tg

|

>280

|

|

℃TMA

|

A

|

IPC-TM-650

2.4.24.3

|

|

Td

|

390

|

|

℃TGA

|

|

ASTM

D 3850

|

|

Thermal Conductivity

|

0.69

|

|

W/M/oK

|

80℃

|

ASTM

C518

|

|

Moisture Absorption

|

0.06

|

|

%

|

48hrs

immersion 0.060"

sample Temperature 50℃

|

ASTM

D 570

|

|

Density

|

1.86

|

|

gm/cm3

|

23℃

|

ASTM

D 792

|

|

Copper Peel Stength

|

0.88

(5.0)

|

|

N/mm

(pli)

|

after

solder float 1 oz.

EDC Foil

|

IPC-TM-650

2.4.8

|

|

Flammability

|

(3)V-0

|

|

|

|

UL

94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

Typical

applications are as follows:

Automotive

Radar and Sensors

Cellular

Base Station Antennas

Direct

Broadcast Satellites

Low

Noise Block

Power

amplifiers

RFID

Data

sheet of Rogers 4350B (RO4350B ):

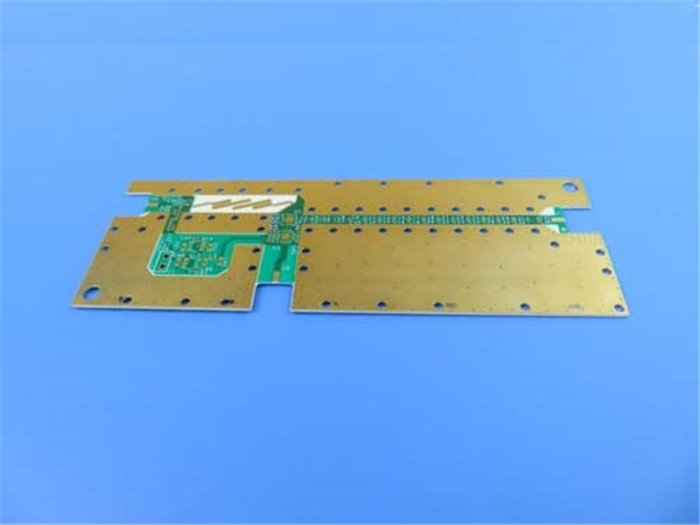

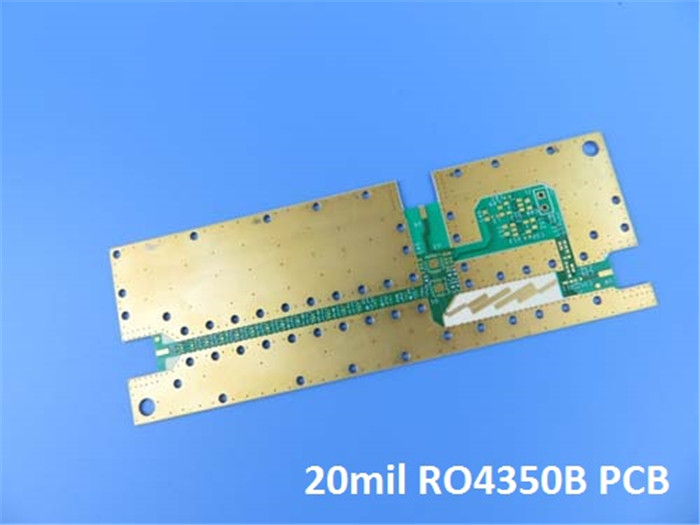

|

PCB SIZE

|

26 x 83mm=1PCS

|

|

BOARD TYPE

|

|

|

Number

of Layers

|

Double sided

PCB, 2 Layer PCB

|

|

Surface

Mount Components

|

YES

|

|

Through

Hole Components

|

no

|

|

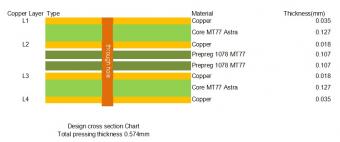

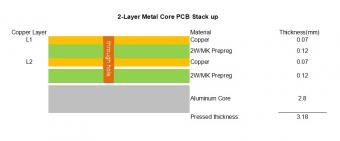

LAYER STACKUP

|

copper

------- 35um(1oz)+plate TOP layer

|

|

RO4350B 20mil (0.508mm)

|

|

copper ------- 35um(1oz)+plate BOT Layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

5.98mil/6.18mil

|

|

Minimum

/ Maximum Holes:

|

0.3/3.2mm

|

|

Number

of Different Holes:

|

5

|

|

Number

of Drill Holes:

|

431

|

|

Number

of Milled Slots:

|

0

|

|

Number

of Internal Cutouts:

|

no

|

|

Impedance

Control

|

no

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

RO4350B 20mil (0.508mm), Tg 288℃

|

|

Final

foil external:

|

1.5oz

|

|

Final

foil internal:

|

0oz

|

|

Final

height of PCB:

|

0.6mm

±0.1

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

Immersion

Gold (81.1%) 2µ" over 100µ" nickel

|

|

Solder

Mask Apply To:

|

Top and Bottom,

12micron Minimum

|

|

Solder

Mask Color:

|

Green, LP-4G

G-05, Nanya supplied

|

|

Solder

Mask Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of

Component Legend

|

TOP

|

|

Colour

of Component Legend

|

White, S-380W,

Taiyo Supplied.

|

|

Manufacturer

Name or Logo:

|

Marked on the

board in a conductor and leged FREE AREA

|

|

VIA

|

Plated

Through Hole(PTH)

|

|

FLAMIBILITY RATING

|

UL

94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

(0.15mm)

|

|

Board

plating:

|

0.0030"

(0.076mm)

|

|

Drill

tolerance:

|

0.002"

(0.05mm)

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com