TC350

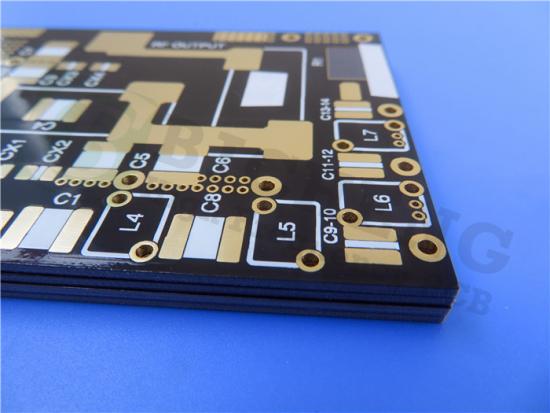

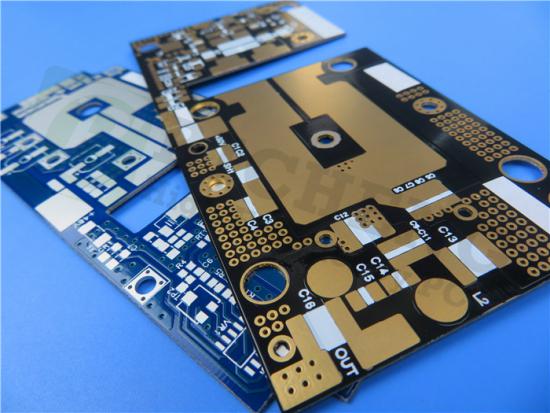

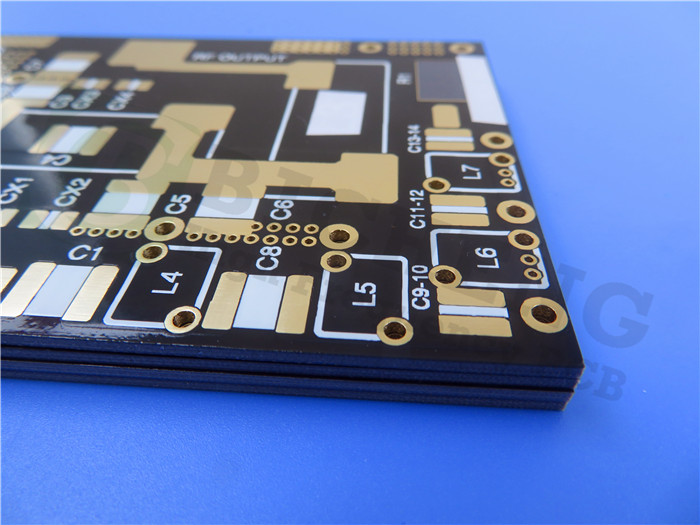

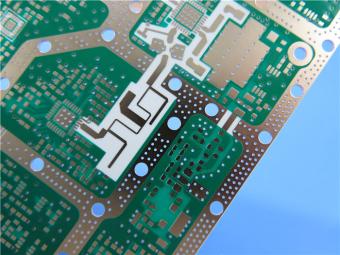

Rogers RF PCB Built on 30mil Double Sided Corel With Immersion Gold for Tower

Mounted Amplifiers

Rogers'

TC350 is a woven fiberglass reinforced, ceramic filled, PTFE based composite

for use as making printed circuit board.

Features

& Benefits:

1.

The increased thermal conductivity of TC350 provides higher power handling,

reduces hot-spots and improves device reliability. This results in reduced

junction temperatures and extends the life of active components, which is

critical for improving power amplifier reliability, extending MTBF and reducing

warranty costs.

2.

TC350 has excellent Dielectric Constant Stability across a wide temperature

range. This helps Power Amplifier and Antenna designers maximize gain and

minimize dead bandwidth lost to dielectric constant drift as operating

temperature changes.

3.

TC350 enjoys a strong bond to copper, utilizing microwave grade, low profile

copper. This results in even lower insertion loss due to skin effect losses of

copper that are more obvious at higher RF and microwave frequencies.

Our

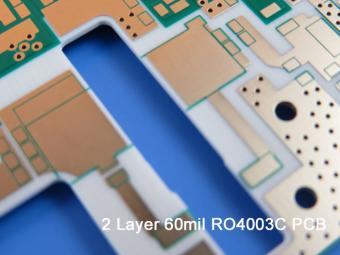

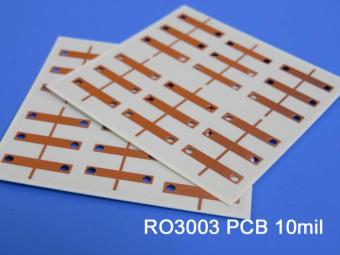

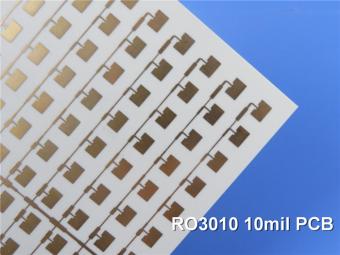

PCB Capabilities (TC350):

|

PCB

Material:

|

Woven

Fiberglass Reinforced, Ceramic Filled, PTFE based Composite

|

|

Designation:

|

TC350

|

|

Dielectric constant:

|

3.5±0.05

|

|

Thermal Conductivity

|

0.72 W/m-K

|

|

Dissipation Factor

|

Df .002@10 GHz

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

10mil

(0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP, Immersion tin etc..

|

Typical

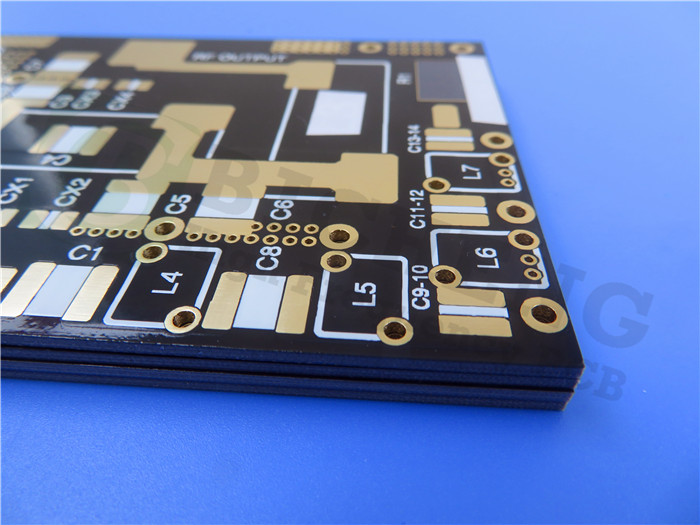

Applications:

1.

Microwave Combiner and Power Dividers

2.

Power Amplifiers, Filters and Couplers

3.

Tower Mounted Amplifiers (TMA) and Tower Mounted Boosters (TMB)

4.

Thermally Cycled Antennas sensitive to dielectric drift

Typical

Properties of TC350:

|

Typical

Properties:TC350

|

|

Property

|

Units

|

Value

|

Test Merthod

|

|

1. Electrical

Properties

|

|

|

Dielectric

Constant (may vary by thickness)

|

|

|

|

|

@1 MHz

|

-

|

3.50

|

IPC TM-650 2.5.5.3

|

|

@1.8 GHz

|

-

|

3.50

|

RESONANT CAVITY

|

|

@10 GHz

|

-

|

3.50

|

IPC TM-650 2.5.5.5

|

|

Dissipation Factor

|

|

|

|

|

@1 MHz

|

-

|

0.0015

|

IPC TM-650 2.5.5.3

|

|

@1.8 GHz

|

-

|

0.0018

|

RESONANT CAVITY

|

|

@10 GHz

|

-

|

0.0020

|

IPC TM-650 2.5.5.5

|

|

Temperature

Coefficient of Dielectric

|

-

|

|

|

|

TC r @ 10 GHz (-40-150°C)

|

ppm/ºC

|

-9

|

IPC TM-650 2.5.5.5

|

|

Volume

Resistivity

|

|

|

|

|

C96/35/90

|

MΩ-cm

|

7.4x106

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ-cm

|

1.4x108

|

|

|

Surface Resistivity

|

|

|

|

|

C96/35/90

|

MΩ

|

3.2x107

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ

|

4.3x108

|

IPC TM-650 2.5.17.1

|

|

Electrical Strength

|

Volts/mil (kV/mm)

|

780 (31)

|

IPC TM-650 2.5.6.2

|

|

Dielectric Breakdown

|

kV

|

40

|

IPC TM-650 2.5.6

|

|

Arc Resistance

|

sec

|

>240

|

IPC TM-650 2.5.1

|

|

2.Thermal

Properties

|

|

|

Decomposition

Temperature (Td)

|

|

|

|

|

Initial

|

°C

|

520

|

IPC TM-650 2.4.24.6

|

|

5%

|

°C

|

567

|

IPC TM-650 2.4.24.6

|

|

T260

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T288

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T300

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

Thermal

Expansion, CTE (x,y) 50-150ºC

|

ppm/ºC

|

7, 7

|

IPC TM-650 2.4.41

|

|

Thermal

Expansion, CTE (z) 50-150ºC

|

ppm/ºC

|

12

|

IPC TM-650 2.4.24

|

|

% z-axis

Expansion (50-260ºC)

|

%

|

1.2

|

IPC TM-650 2.4.24

|

|

3. Mechanical

Properties

|

|

|

Peel Strength

to Copper (1 oz/35 micron)

|

|

|

|

|

After Thermal Stress

|

lb/in (N/mm)

|

7 (1.2)

|

IPC TM-650 2.4.8

|

|

At Elevated

Temperatures (150ºC)

|

lb/in (N/mm)

|

9 (1.6)

|

IPC TM-650 2.4.8.2

|

|

After Process Solutions

|

lb/in (N/mm)

|

7 (1.2)

|

IPC TM-650 2.4.8

|

|

Young’s

Modulus

|

kpsi (MPa)

|

|

IPC TM-650 2.4.18.3

|

|

Flexural

Strength (Machine/Cross)

|

kpsi (MPa)

|

14/10 (97/69)

|

IPC TM-650 2.4.4

|

|

Tensile

Strength (Machine/Cross)

|

kpsi (MPa)

|

11/8 (76/55)

|

IPC TM-650 2.4.18.3

|

|

Compressive

Modulus

|

kpsi (MPa)

|

|

ASTM D-3410

|

|

Poisson’s

Ratio

|

-

|

|

ASTM D-3039

|

|

4. Physical

Properties

|

|

|

Water

Absorption

|

%

|

0.05

|

IPC TM-650 2.6.2.1

|

|

Density,

ambient 23ºC

|

g/cm3

|

2.30

|

ASTM D792 Method A

|

|

Thermal

Conductivity

|

W/mK

|

0.72

|

ASTMD5470

|

|

Specific Heat

|

J/gK

|

0.90

|

ASTM D5470

|

|

Flammability

|

class

|

V0

|

UL-94

|

|

NASA

Outgassing, 125ºC, ≤10- 6 torr

|

|

|

|

|

Total Mass

Loss

|

%

|

0.02

|

NASA SP-R-0022A

|

|

Collected

Volatiles

|

%

|

0.01

|

NASA SP-R-0022A

|

|

Water Vapor

Recovered

|

%

|

0.01

|

NASA SP-R-0022A

|

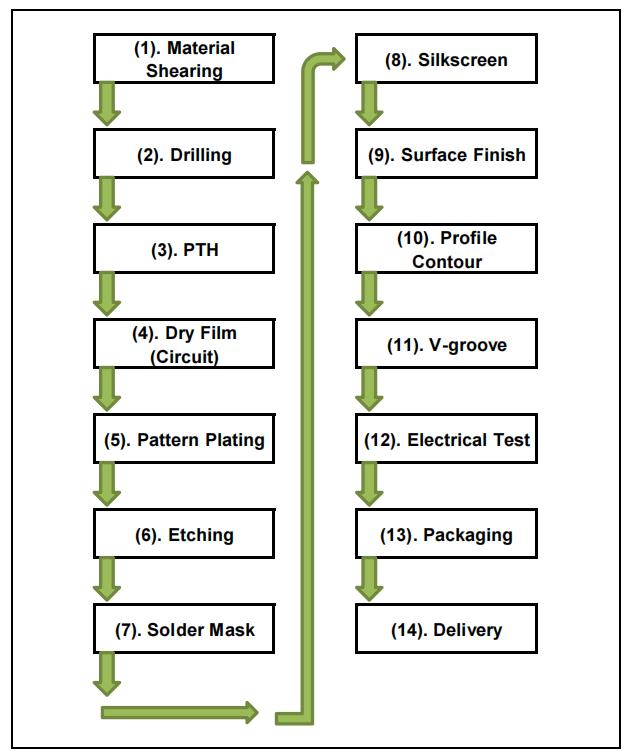

PCB MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com