Rogers

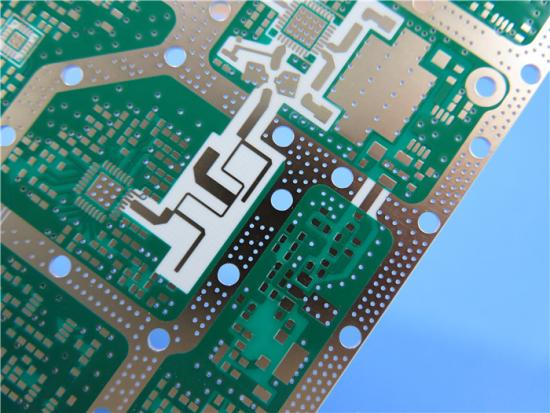

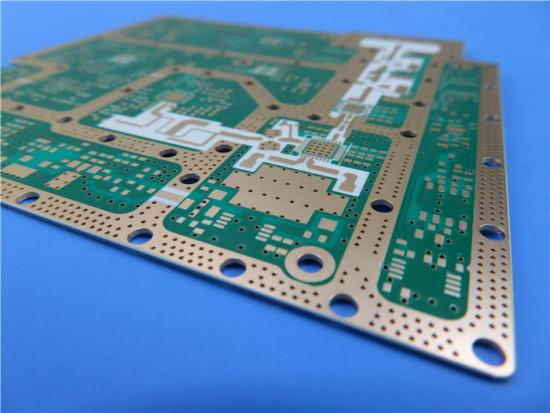

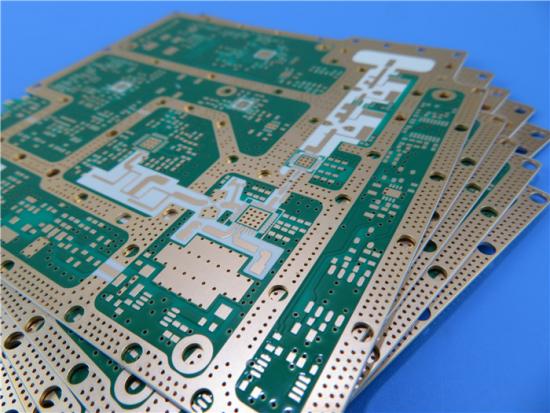

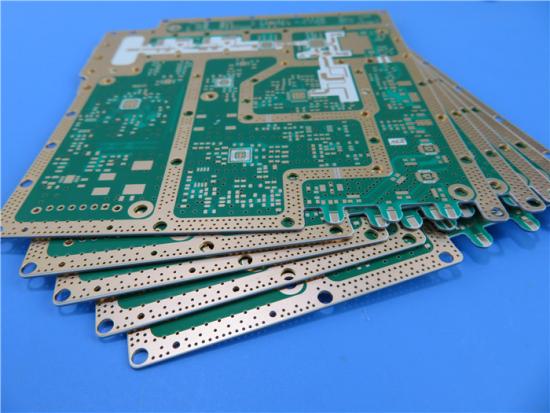

6035 High Frequency PCB Built On Double Sided 20mil Core With Immersion Gold for

Power Amplifiers

RT/duroid

6035HTC high frequency circuit materials of Rogers Corporation are ceramic

filled PTFE composites for use in high power RF and microwave applications.

With a thermal conductivity of almost 2.4 times the standard RT/duroid 6000

products, and

copper

foil (electrodeposited and reverse treat) with excellent long term thermal

stability, RT/duroid 6035HTC laminates are an exceptional choice for high power

applications.

Features/Benefits:

1.

High Thermal conductivity

Improved

dielectric heat dissipation enables lower operating temperatures for high power

applications

2.

Low loss tangent

Excellent

high frequency performance

3.

Thermally stable low profile and reverse treat copper foil

Lower

insertion loss and excellent thermal stability of traces

4.

Advanced filler system

Improved

drill ability and extended tool life compared to alumina containing circuit

materials

Some

Typical Applications:

1.

High Power RF and Microwave Amplifiers

2.

Power Amplifiers, Couplers, Filters

3.

Combiners, Power Dividers

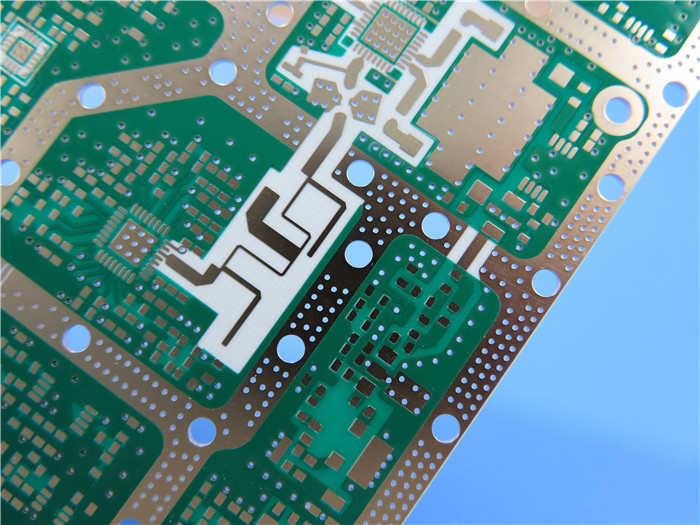

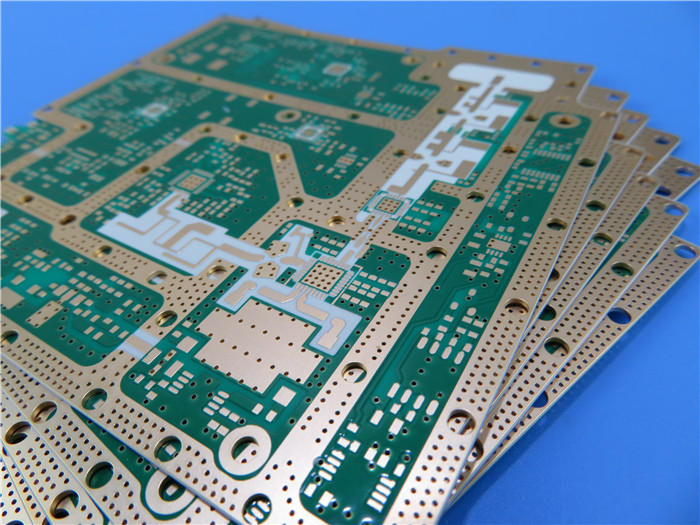

PCB

Capability(RT/duroid 6035HTC):

|

PCB

Material:

|

Ceramic-filled

PTFE composites

|

|

Designation:

|

RT/duroid 6035HTC

|

|

Dielectric constant:

|

3.50±0.05

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

10mil

(0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP etc..

|

Data

Sheet of RT/duroid 6035HTC:

|

RT/duroid

6035HTC Typical Value

|

|

Property

|

RT/duorid 6035HTC

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.50±0.05

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5 Clamped Stripline

|

|

Dielectric Constant,εDesign

|

3.6

|

Z

|

|

8 GHz - 40

GHz

|

Differential Phase Length Method

|

|

Dissipation

Factor

|

0.0013

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of ε

|

-66

|

Z

|

ppm/℃

|

-50℃to 150℃

|

mod IPC-TM-650, 2.5.5.5

|

|

Volume Resistivity

|

108

|

|

MΩ.cm

|

A

|

IPC-TM-650, 2.5.17.1

|

|

Surface Resistivity

|

108

|

|

MΩ

|

A

|

IPC-TM-650, 2.5.17.1

|

|

Dimensional Stability

|

-0.11 -0.08

|

CMD MD

|

mm/m

(mils/inch)

|

0.030"

1oz EDC foil Thickness after etch '+E4/105

|

IPC-TM-650 2.4.39A

|

|

Tensile Modulus

|

329 244

|

MD CMD

|

kpsi

|

40 hrs @23℃/50RH

|

ASTM D638

|

|

Moisure Absorption

|

0.06

|

|

%

|

D24/23

|

IPC-TM-650 2.6.2.1 ASTM D570

|

Coefficient of Thermal Expansion (-50℃to 288℃)

|

19 19 39

|

X Y Z

|

ppm/℃

|

23℃/ 50% RH

|

IPC-TM-650 2.4.41

|

|

Thermal Conductivity

|

1.44

|

|

W/m/k

|

80℃

|

ASTM C518

|

|

Density

|

2.2

|

|

gm/cm3

|

23℃

|

ASTM D792

|

|

Copper Peel Stength

|

7.9

|

|

pli

|

20 sec. @288℃

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-Free Process Compatible

|

Yes

|

|

|

|

|

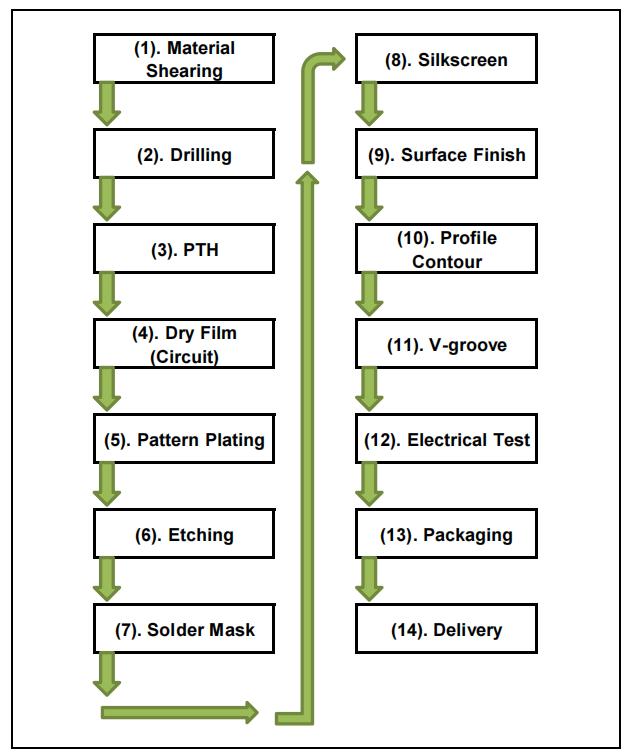

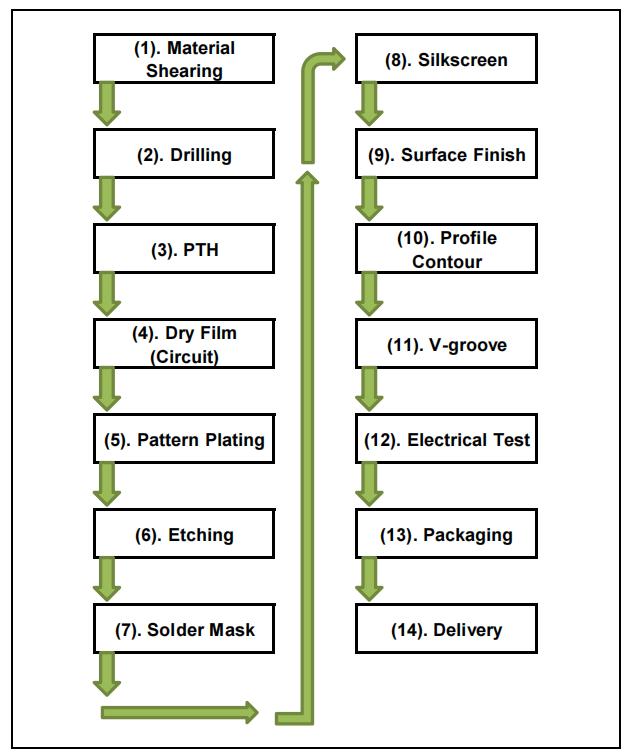

PCB MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com