Low

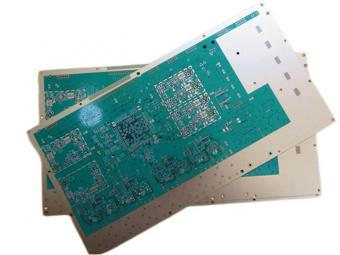

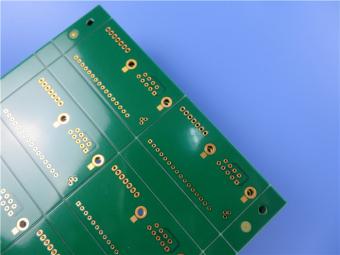

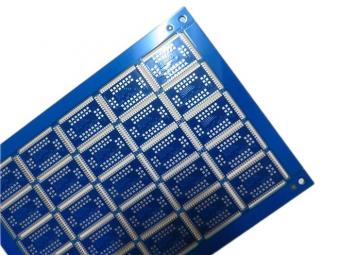

Dk / Df FR-4 PCB High Thermal Reliability Printed Circuit Board (PCB) TU-872

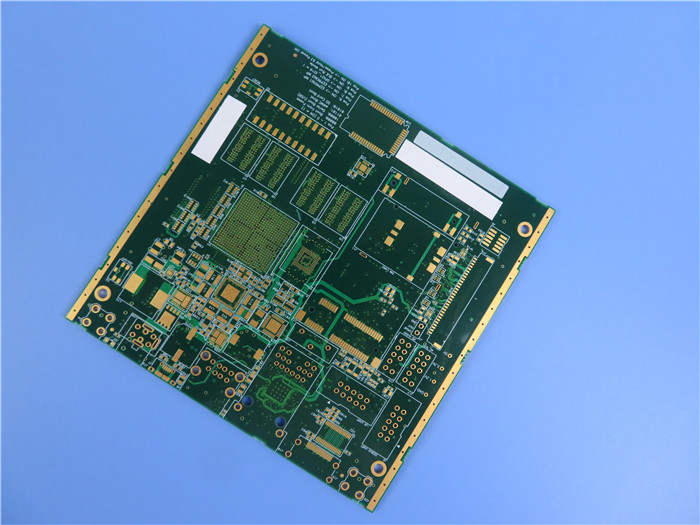

Multilayer PCB

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

General

Description

TU-872 SLK Sp material is suitable for environmental

protection lead free process and also compatible with FR-4 processes. TU-872

SLK Sp laminates also exhibit excellent CTE, superior chemical resistance,

moisture resistance, thermal stability, CAF resistance and toughness enhanced

by an allyl network forming compound.

Key

Features

1.

Excellent electrical properties

2.

Dielectric constant less than 3.5

3.

Dissipation factor less than 0.010

4.

Excellent, stable and flat Dk/Df performance

5.

Compatible with most FR-4 processes

6.

Lead free process compatible

7.

Improved z-axis thermal expansion

8.

Anti-CAF capability

9.

Superior dimensional stability, thickness uniformity and flatness

10.

Excellent through-hole and soldering reliability

Our

PCB Capabilities (TU-872 SLK Sp)

|

PCB

Material:

|

High

performance modified epoxy FR-4 resin

|

|

Designation:

|

TU-872

SLK Sp

|

|

Dielectric constant:

|

<

3.5

|

|

Layer count:

|

Double

Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz

(17 µm), 1oz (35µm), 2oz (70µm), 3oz (105µm), 4oz (140µm), 5oz (175µm)

|

|

PCB thickness:

|

10mil

(0.254mm), 15mil (0.381mm), 20mil (0.508mm), 25mil(0.635mm), 30mil (0.762mm),

60mil(1.524mm)

|

|

PCB size:

|

≤400mm

X 500mm

|

|

Solder mask:

|

Green,

Black, Matt Black, Blue, Matt Blue, Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, OSP, Immersion tin, Immersion Silver etc..

|

|

Technology:

|

HDI,

Via in pad, Impedance Control, Blind via/Buried via, Edge Plating, BGA,

Countsunk Holes etc.

|

Main

Applications

1.

Radio Frequency

2.

Backpanel, High performance computing

3.

Line cards, Storage

4.

Servers, Telecom, Base station

5.

Office Routers

Our

Advantages

ISO9001,

ISO14001, IATF16949, ISO13485, UL Certified;

16000㎡workshop;

30000㎡output capability per month;

Prototype

to large volume production capability

IPC

Class 2 / IPC Class 3;

Any

layer HDI PCBs;

Delivery

on time: >98%

Customer

complaint rate: <1%

Typical

Properties (TU-872 SLK Sp)

|

Typical

Properties for TU-872 SLK Sp Laminate

|

|

|

Typical Values

|

Conditioning

|

IPC-4101 /126

|

|

Thermal

|

|

|

|

|

Tg

(DMA)

|

220°C

|

|

|

|

Tg

(DSC)

|

200°C

|

|

> 170°C

|

|

Tg

(TMA)

|

190°C

|

E-2/105

|

|

|

Td

(TGA)

|

340°C

|

|

> 340°C

|

|

CTE x-axis

|

12~15 ppm/°C

|

|

N/A

|

|

CTE

y-axis

|

12~15 ppm/°C

|

E-2/105

|

N/A

|

|

CTE

z-axis

|

2.30%

|

|

< 3.0%

|

|

Thermal Stress,Solder Float, 288°C

|

> 60 sec

|

A

|

> 10 sec

|

|

T260

|

60 min

|

|

> 30 min

|

|

T288

|

20 min

|

E-2/105

|

> 15 min

|

|

T300

|

5 min

|

|

> 2 min

|

|

Flammability

|

94V-0

|

E-24/125

|

94V-0

|

|

DK &

DF

|

|

|

|

|

Permittivity

(RC 50%) @10GHz

|

3.5

|

|

|

|

Loss

Tangent (RC 50%) @10GHz

|

0.008

|

|

|

|

Electrical

|

|

|

|

|

Permittivity

(RC50%)

|

|

|

|

|

1GHz

(SPC method/4291B)

|

3.6/3.4

|

|

< 5.2

|

|

5GHz

(SPC method)

|

3.5

|

E-2/105

|

-

|

|

10GHz

(SPC method)

|

3.5

|

|

-

|

|

Loss Tangent (RC50%)

|

|

|

|

|

1GHz

(SPC method/4291B)

|

0.006/0.004

|

|

|

|

5GHz

(SPC method)

|

0.007

|

E-2/105

|

< 0.035

|

|

10GHz

(SPC method)

|

0.008

|

|

|

|

Volume Resistivity

|

> 1010 MΩ•cm

|

C-96/35/90

|

> 106 MΩ•cm

|

|

Surface

Resistivity

|

> 108 MΩ

|

C-96/35/90

|

> 104 MΩ

|

|

Electric

Strength

|

> 40 KV/mm

|

A

|

> 30 kV/mm

|

|

Dielectric

Breakdown

|

> 50 kV

|

A

|

N/A

|

|

Mechanical

|

|

|

|

|

Young’s

Modulus

|

|

|

|

|

Warp

Direction

|

26 GPa

|

A

|

N/A

|

|

Fill

Direction

|

24 GPa

|

|

|

|

Flexural Strength

|

|

|

|

|

Lengthwise

|

> 60,000 psi

|

A

|

> 60,000 psi

|

|

Crosswise

|

> 50,000 psi

|

A

|

> 50,000 psi

|

|

Peel Strength, 1.0 oz RTF Cu foil

|

4~7 lb/in

|

A

|

> 4 lb/in

|

|

Water

Absorption

|

0.13%

|

E-1/105+D-24/23

|

< 0.5 %

|

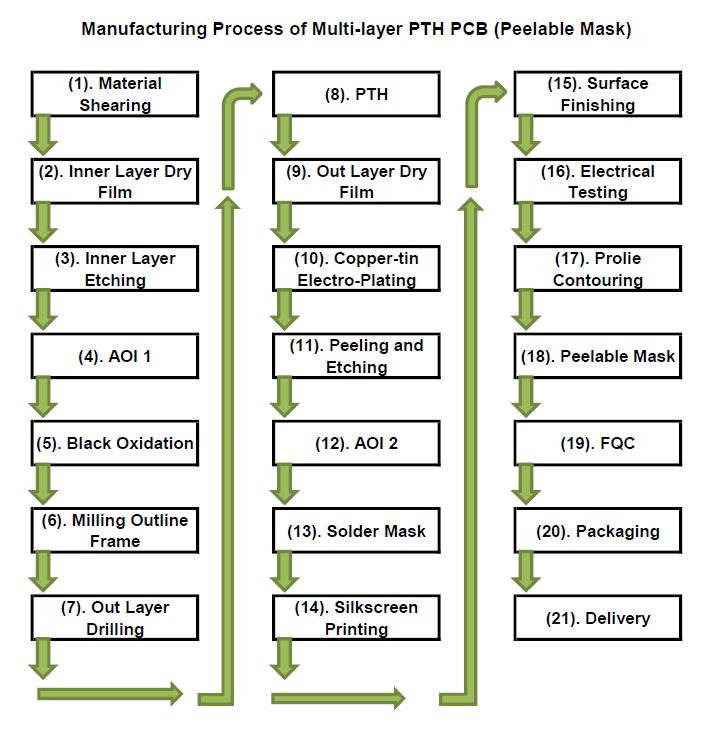

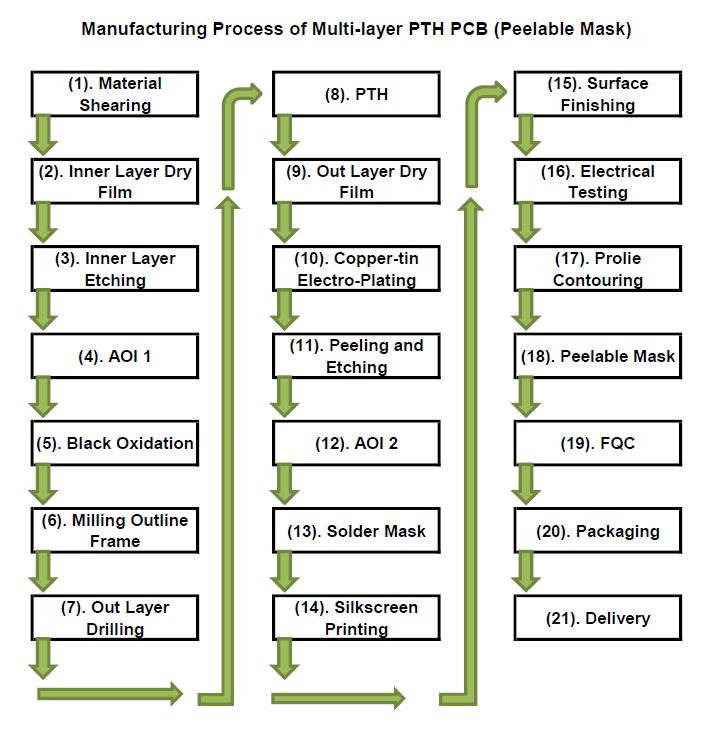

MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com