RF

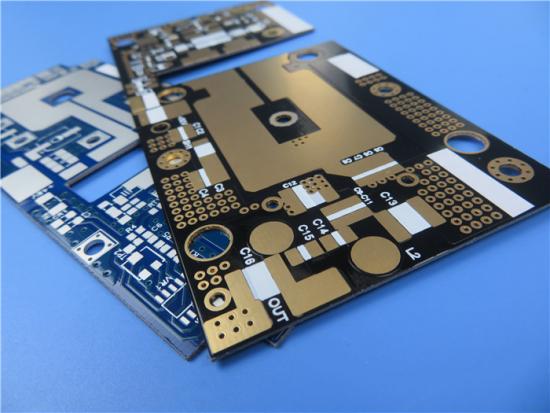

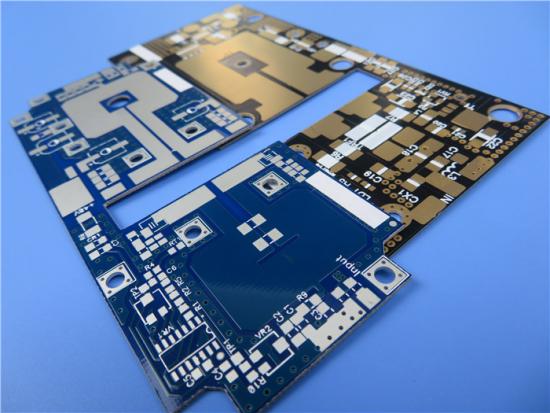

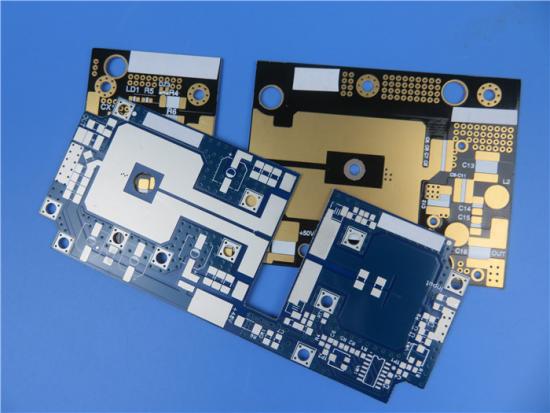

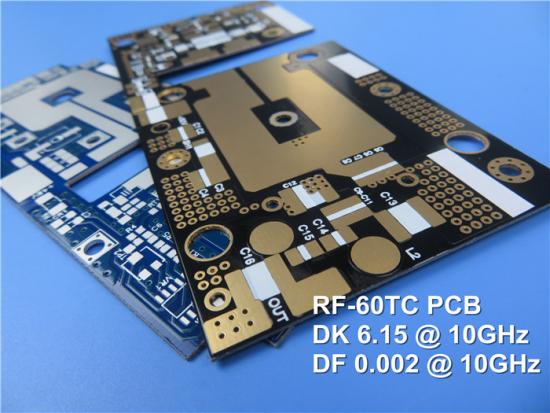

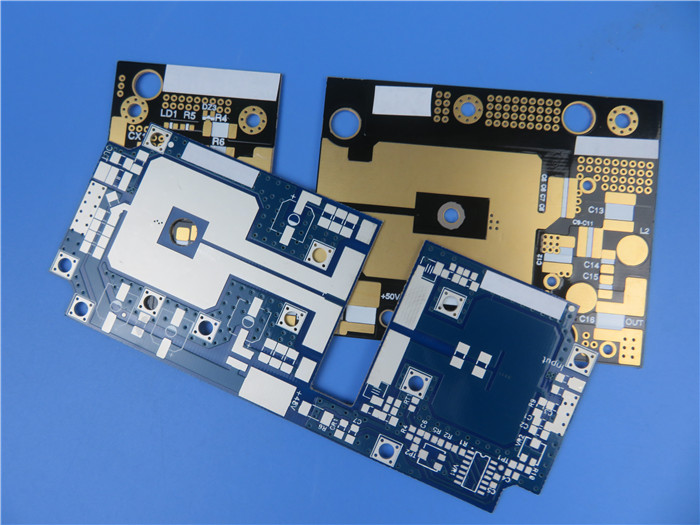

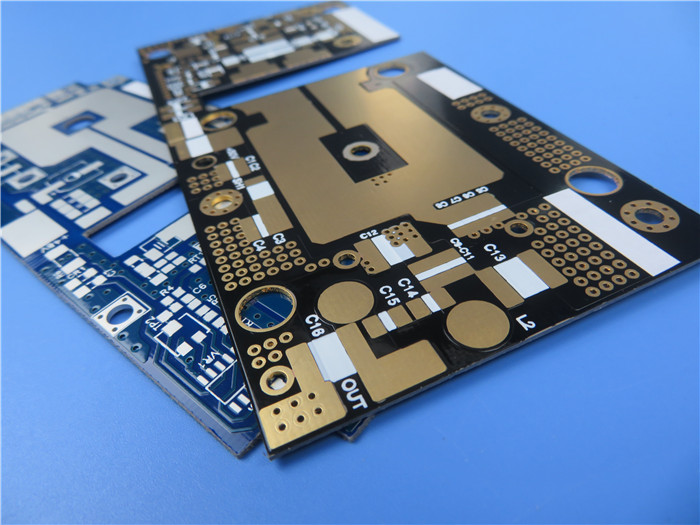

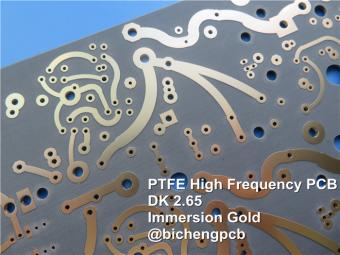

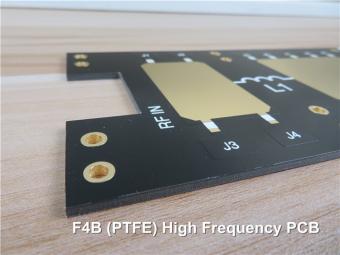

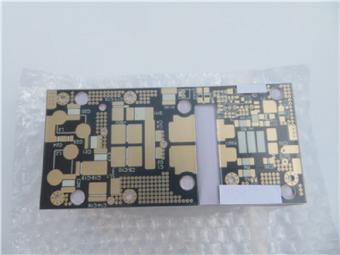

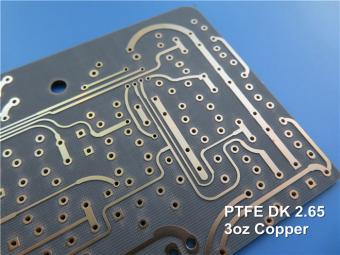

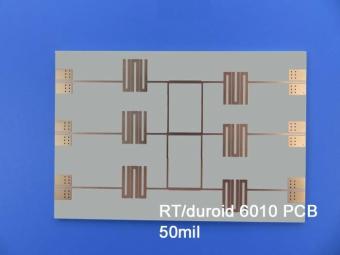

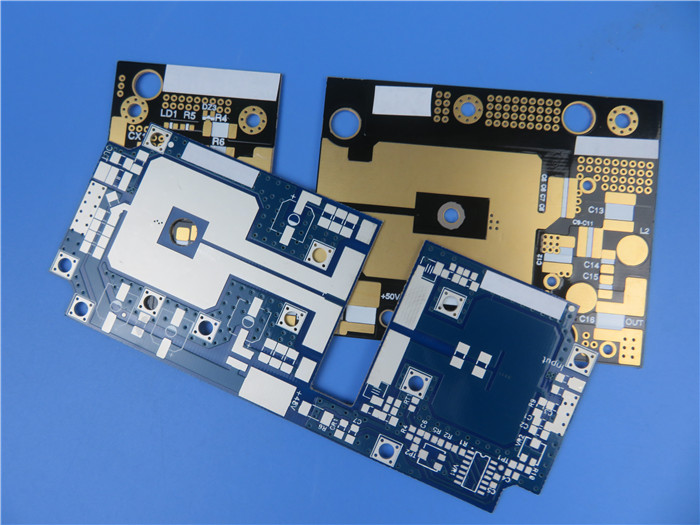

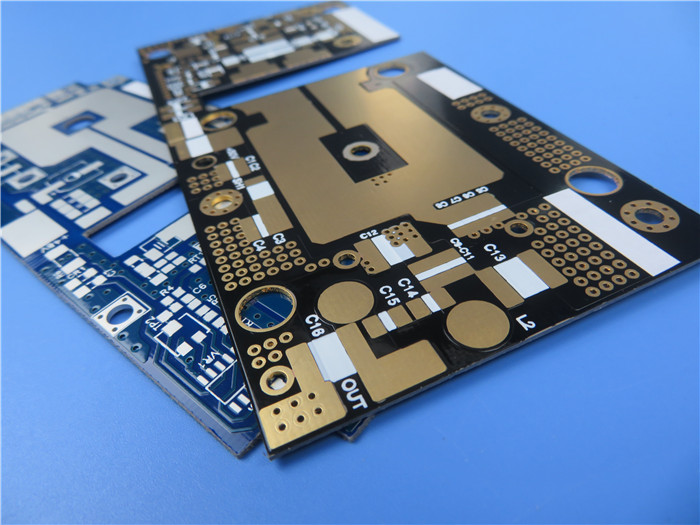

PCB Built on 6.15 DK RF-60TC 10mil, 20mil, 30mil and 60mil Coating with

Immersion Gold, Tin, HASL and OSP for Miniaturized Antenna

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

RF-60TC

is a ceramic-filled PolyTetraFluoride(PTFE) based (fiberglass substrate for the

PCB of high power RF and microwave applications. It is designed to provide

lower operating temperature in high power applications and the 6.15DK market.

RF-60TC's

enhanced heat transfer function allows additional design margin to extend the

life of active components and improve long-term reliability.

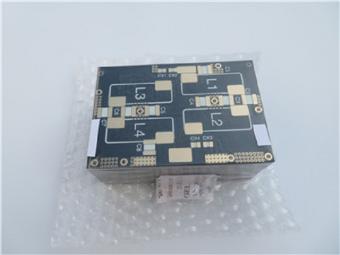

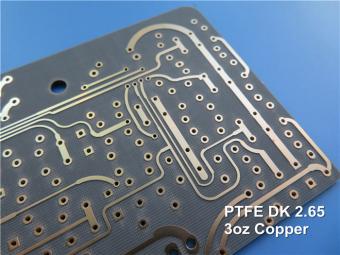

RF-60TC

with extremely low profile and reverse treated copper is excellent to reduce

insertion loss. Heavy metal based laminate is also available. RF-60TC’s low CTE

and improved dimensional stability make it possible to build multi-layer PCB

with improved PTH reliability.

Our

PCB Capability (RF-60TC):

|

PCB

Material:

|

PTFE based,

ceramic filled fiberglass

|

|

Designation:

|

RF-60TC

|

|

Dielectric constant:

|

6.15

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm)

|

|

PCB thickness:

|

10mil (0.254mm); 20mil (0.508mm),

25mil(0.635mm); 30mil (0.762mm), 60mil

(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, Immersion silver, Immersoin tin, OSP etc..

|

Benefits:

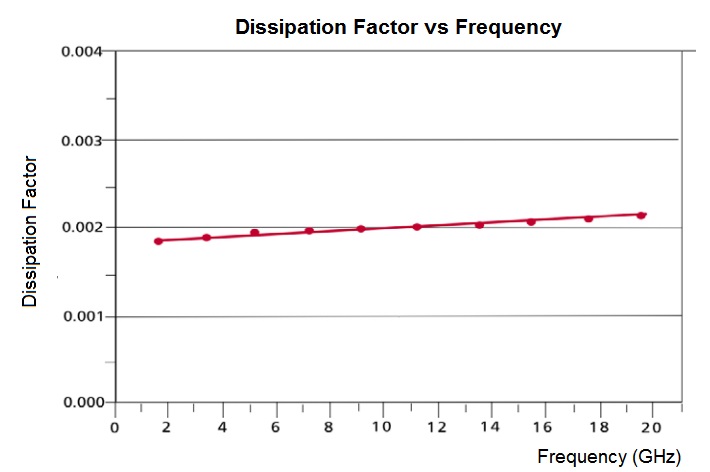

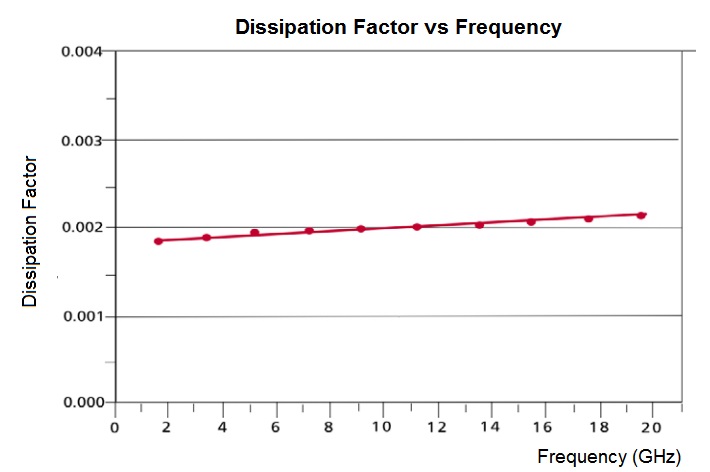

1.Improved loss tangent

-

Lower insertion loss

-

Enhanced antenna gain / efficiency

2.High thermal conductivity

-

Exceptional thermal management

-

Lower operating temperature

-

Higher power application

-

Loong term reliablity

3.Enhanced dimensional stability

4.Low Z-axis CTE

-

Multilayer application available

- Reliable

plated through hole

5.Excellent adhesion to metal

-

Lower profile copper available

-

Heavy metal back available

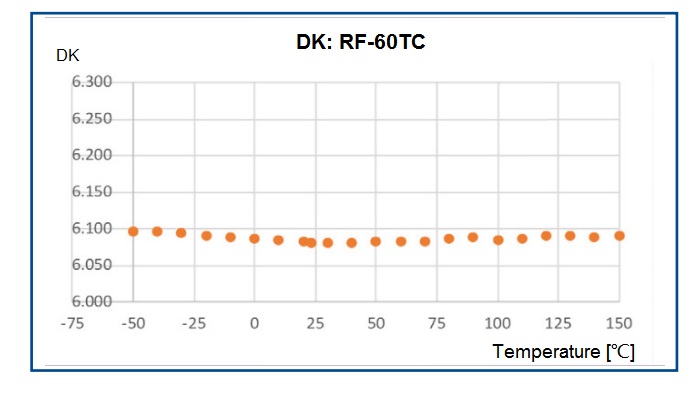

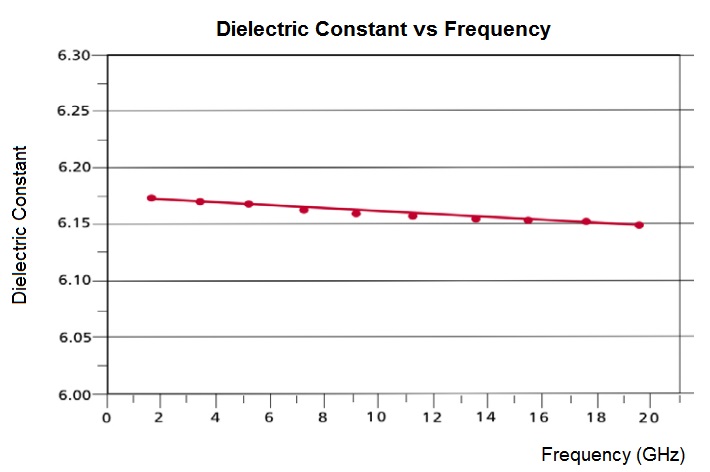

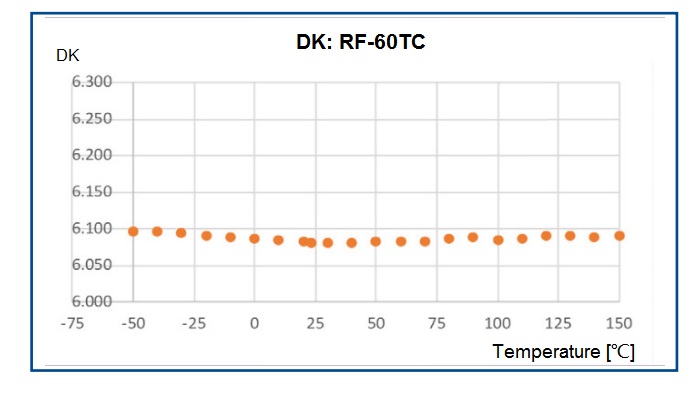

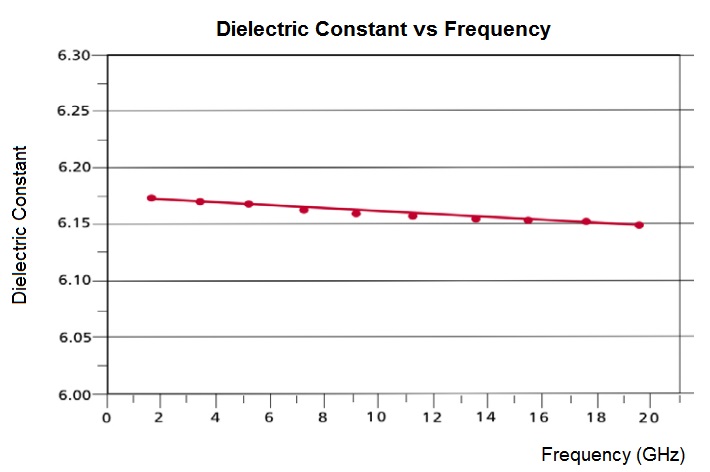

6.Stable DK over frequency

7.Stable DK over temperature

8.Low moisture absorption

Applications:

High

power amplifier

Miniaturized

antennas (GPS / PATCH / RFID Reader)

Filters,

couplers, dividers

Satellites

Typical

Value of RF-60TC:

|

RF-60TC

Typical Values

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

Dk @ 10 GHz

|

IPC-650 2.5.5.5.1(Modified)

|

|

6.15 ± 0.15

|

|

6.15 ± 0.15

|

|

Df @ 10 GHz

|

IPC-650 2.5.5.5.1(Modified)

|

|

0.002

|

|

0.002

|

|

TcK

|

|

ppm/°C

|

-3.581

|

ppm/°C

|

-3.581

|

|

Dielectric

Breakdown

|

IPC-650 2.5.6

|

kV

|

55

|

kV

|

55

|

|

Dielectric

Strength

|

IPC-650 2.5.6.2

|

V/mil

|

550

|

V/mm

|

21,654

|

|

Arc Resistance

|

IPC-650 2.5.1

|

Seconds

|

>180

|

Seconds

|

>180

|

|

Moisture

Absorption

|

IPC-650 2.6.2.1

|

%

|

0.03

|

%

|

0.03

|

|

Flexural

Strength(MD)

|

IPC-650 2.4.4

|

psi

|

10,000

|

N/mm2

|

69

|

|

Flexural

Strength(CD)

|

IPC-650 2.4.4

|

psi

|

9,000

|

N/mm2

|

62

|

|

Tensile

Strength(MD)

|

IPC-650 2.4.19

|

psi

|

9,000

|

N/mm2

|

62

|

|

Tensile

Strength(CD)

|

IPC-650 2.4.19

|

psi

|

7,000

|

N/mm2

|

48

|

|

Young’s

Modulus(MD)

|

ASTM D

3039/IPC-TM-650 2.4.19

|

kpsi

|

721

|

N/mm2

|

4971

|

|

Poisson’s

Ratio(MD)

|

ASTM D

3039/IPC-TM-650 2.4.19

|

|

0.155

|

|

0.155

|

|

Peel Strength(1 oz. ED)

|

IPC-650 2.4.8

|

lbs/in

|

8

|

N/mm

|

1.43

|

|

Thermal

Conductivity(Unclad)

|

IPC-650 2.4.50

|

W/M*K

|

0.9

|

W/M*K

|

0.9

|

|

Thermal

Conductivity(CH/CH)

|

IPC-650 2.4.50

|

W/M*K

|

1

|

W/M*K

|

1

|

|

Thermal

Conductivity(C1/C1)

|

IPC-650 2.4.50

|

W/M*K

|

1.05

|

W/M*K

|

1.05

|

|

Dimensional

Stability(MD)

|

IPC-650 2.4.39 Sec.

5.4(After Bake)

|

mils/in

|

0.01

|

mm/M

|

0.01

|

|

Dimensional

Stability(CD)

|

IPC-650 2.4.39 Sec.

5.4(After Bake)

|

mils/in

|

0.69

|

mm/M

|

0.69

|

|

Dimensional

Stability(MD)

|

IPC-650 2.4.39 Sec.

5.5(Thermal Stress)

|

mils/in

|

0.06

|

mm/M

|

0.06

|

|

Dimensional

Stability(CD)

|

IPC-650 2.4.39 Sec.

5.5(Thermal Stress)

|

mils/in

|

0.8

|

mm/M

|

0.8

|

|

Surface

Resistivity

|

IPC-650 2.5.17.1(After Humidity)

|

Mohm

|

1.0 x 108

|

Mohm

|

1.0 x 108

|

|

Volume

Resistivity

|

IPC-650 2.5.17.1(After Humidity)

|

Mohm/cm

|

1.0 x 108

|

Mohm/cm

|

1.0 x 108

|

|

CTE(X, Y axis)

|

IPC-650 2.4.41(RT- 150°C)

|

ppm/°C

|

9.9

|

ppm/°C

|

9.9

|

|

CTE(Z axis)

|

IPC-650 2.4.41(RT- 150°C)

|

ppm/°C

|

40

|

ppm/°C

|

40

|

|

Density(Specific Gravity)

|

IPC-650 2.3.5

|

g/cm3

|

2.84

|

g/cm3

|

2.84

|

|

Specific Heat

|

IPC-650 2.4.50

|

J/gK

|

0.94

|

J/gK

|

0.94

|

|

Td(2% Wt. Loss)

|

IPC - 650 2.4.24.6 /

TGA

|

°F

|

930

|

°C

|

500

|

|

Td(5% Wt. Loss)

|

IPC - 650 2.4.24.6 /

TGA

|

°F

|

960

|

°C

|

515

|

|

Flammability

Rating

|

UL 94

|

|

V-0

|

|

V-0

|

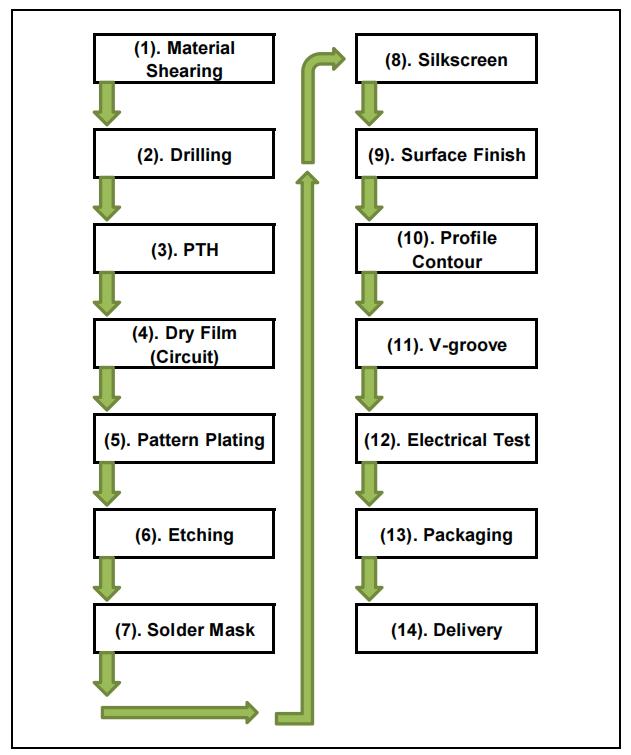

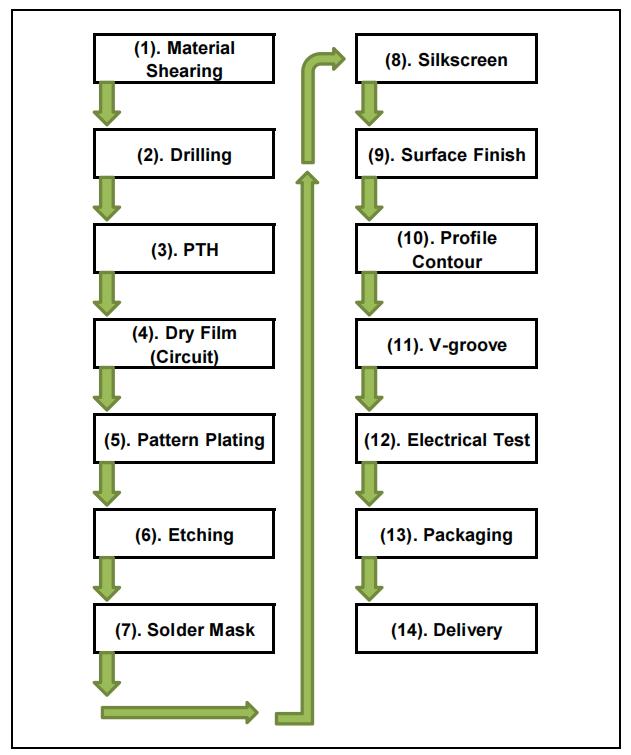

PCB MANUFACTURING PROCESS:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAJOR MATERIAL SUPPLIER:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com