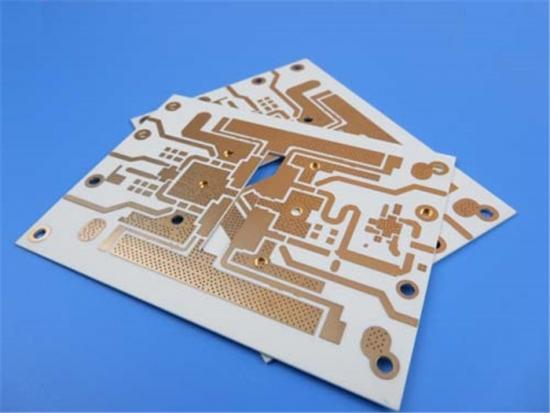

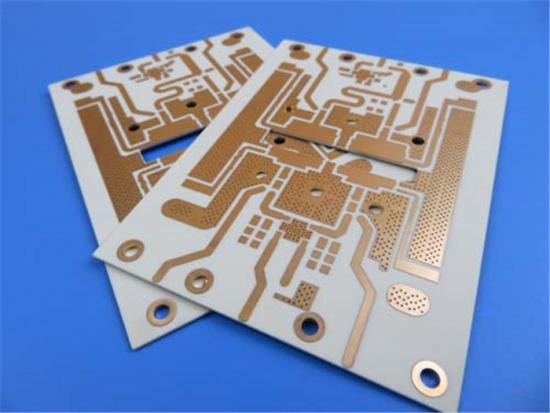

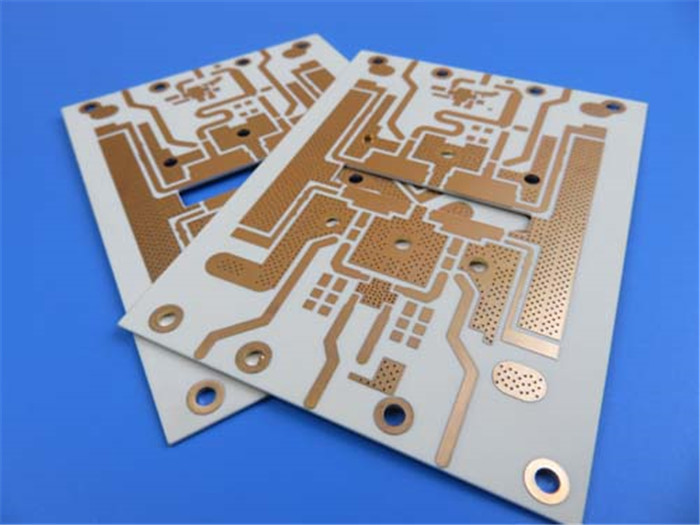

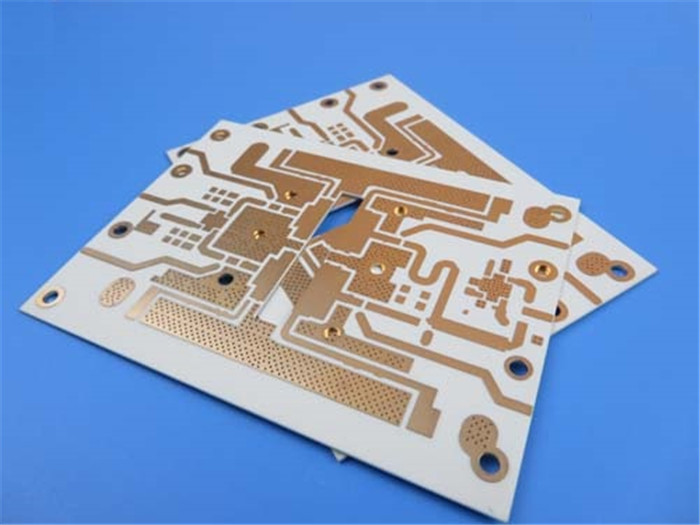

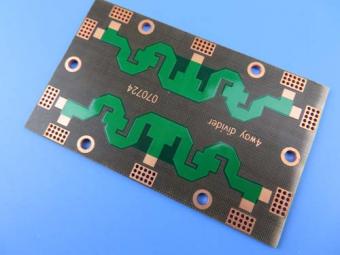

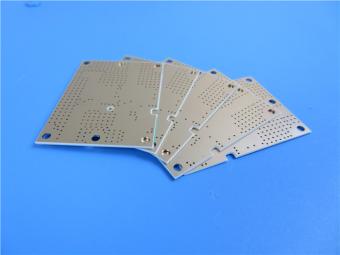

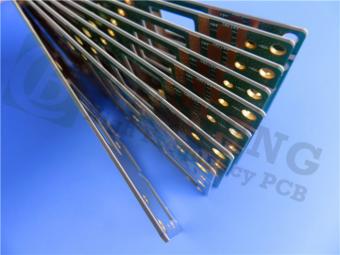

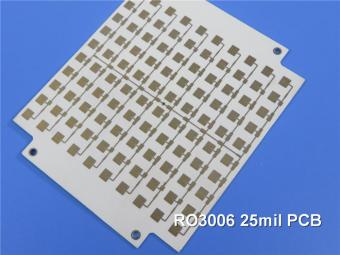

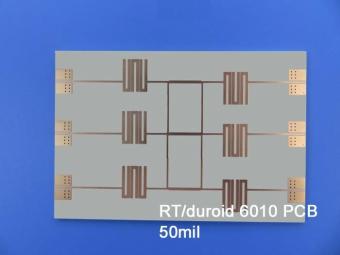

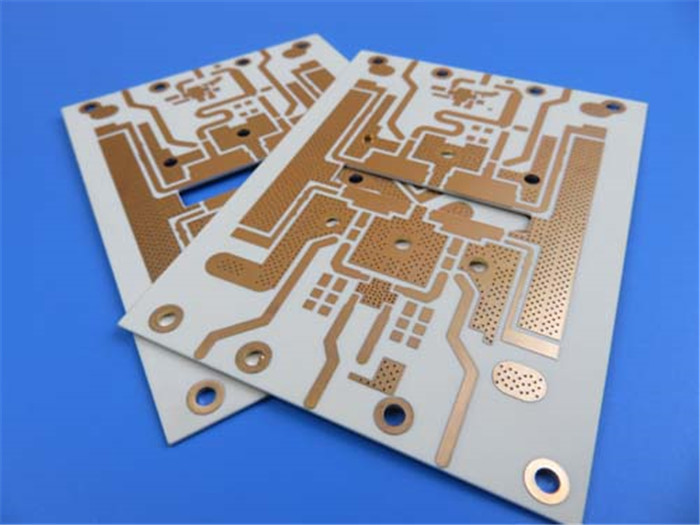

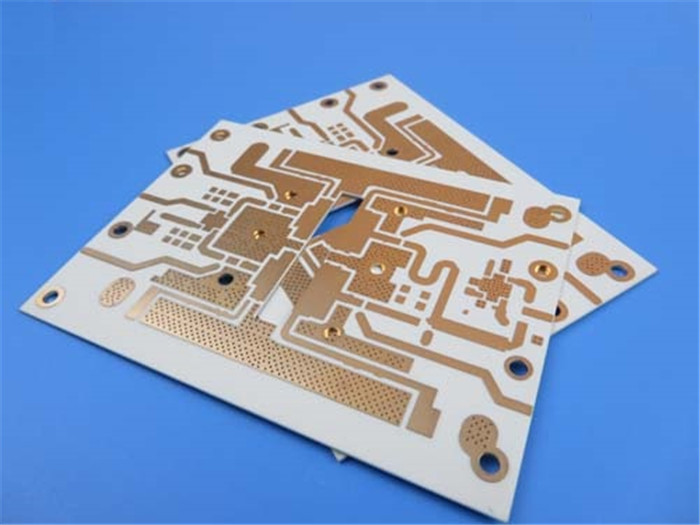

Rogers 4003 32mil 0.813mm PCB RO4003C Double Sided RF High

Frequency PCB for Filters

(Printed Circuit Boards are custom-made

products, the picture and parameters shown are just for reference)

The Rogers RO4003 material can be

removed with conventional nylon brushes. There is no specific preparation

needed prior to copper plating without electricity. The plate needs to be

processed using customary epoxy/glass techniques. Because the high TG resin

system (280 ° C + [536 ° F]) is not susceptible to discoloration during

drilling, it is typically not necessary to remove drilled holes. If the stain

is the product of aggressive drilling techniques, the resin can be removed

using a conventional CF4/O2 plasma cycle or a double pass through an alkaline

permanganate process.

The surfaces of the plates can be

mechanically and/or chemically prepared for photoprotection. It is advised to

use common aqueous or semi-aqueous photoresists. You can utilize any of the

copper wipers that are offered for sale. The surface of Rogers RO4003 accepts

any filterable or photographic solder masks that are typically used in

epoxy/glass laminates quite well. The best bonding should be prevented by

mechanically wiping the exposed dielectric surface before applying the solder

mask and a selected "registered" surface.

HASL and REFLOW:

The baking requirements of RO4000

materials are comparable to those of epoxy/glass. In general, RO4003 plates do

not need to be baked on equipment that does not bake epoxy/glass plates. For

installations that typically create epoxy/bake glass, we advise cooking at 300

°F and 250 °F (121 °C and 149 °C) for one to two hours. There are no flame

retardants in RO4003. It is known that plates running at extremely slow

transport speeds or inside an infrared (IR) unit can attain temperatures of

more than 700 °F (371 °C). At this high temperatures, RO4003 may begin to burn.

Systems that still employ IR reflow units or other components capable of

operating at this high temperatures should take the required safety measures to

eliminate any potential dangers.

life itself:

High-frequency laminates can be kept

indefinitely at standard room conditions of humidity and temperature (55–85 °F,

13–30 °C). The dielectric materials are inert at high humidity when at room

temperature. But when exposed to excessive humidity, metal coatings like copper

can oxidize. Corrosion from materials that have been properly stored can be

removed with ease by doing a standard PWB pre-cleaning.

ROUTE:

The RO4003 material can be machined

using standard epoxy/glass machining equipment and hard metal conditions. In

order to avoid smearing, the copper foil must be taken out of the guiding

channels.

PCB Specifications:

|

PCB SIZE

|

98 x 72mm=1PCS

|

|

BOARD TYPE

|

|

|

Number

of Layers

|

Double sided PCB

|

|

Surface

Mount Components

|

YES

|

|

Through

Hole Components

|

YES

|

|

LAYER STACKUP

|

copper

------- 35um(1oz)+PLATE

|

|

RO4003C 32 mil 0.813mm

|

|

copper ------- 35um(1oz)+PLATE

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

6.98mil/6.28mil

|

|

Minimum

/ Maximum Holes:

|

0.3/1.2mm

|

|

Number

of Different Holes:

|

5

|

|

Number

of Drill Holes:

|

481

|

|

Number

of Milled Slots:

|

0

|

|

Number

of Internal Cutouts:

|

1

|

|

Impedance

Control

|

no

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

RO4003C 32 mil (0.813mm), Tg 288℃

|

|

Final

foil external:

|

1.5oz

|

|

Final

foil internal:

|

0oz

|

|

Final

height of PCB:

|

0.9

mm ±0.1

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

Immersion Gold

|

|

Solder

Mask Apply To:

|

NO

|

|

Solder

Mask Color:

|

NO

|

|

Solder

Mask Type:

|

N/A

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of

Component Legend

|

NO

|

|

Colour

of Component Legend

|

NO

|

|

Manufacturer

Name or Logo:

|

N/A

|

|

VIA

|

Plated

Through Hole(PTH)

|

|

FLAMIBILITY RATING

|

N/A

|

|

DIMENSION TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

(0.15mm)

|

|

Board

plating:

|

0.0030"

(0.076mm)

|

|

Drill

tolerance:

|

0.002"

(0.05mm)

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

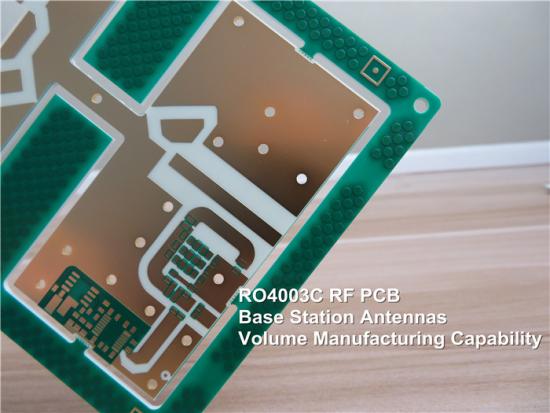

Typical applications are as follows:

Automotive Radar and Sensors

Cellular Base Station Antennas

Direct Broadcast Satellites

Low Noise Block

Power amplifiers

RFID

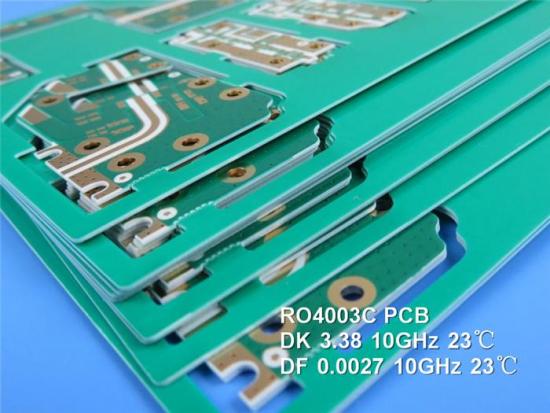

Data Sheet of Rogers 4003C (RO4003C)

|

RO4003C

Typical Value

|

|

Property

|

RO4003C

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric

Constant,εProcess

|

3.38±0.05

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5 Clamped Stripline

|

|

Dielectric Constant,εDesign

|

3.55

|

Z

|

|

8 to 40 GHz

|

Differential

Phase Length Method

|

|

Dissipation Factortan,δ

|

0.0027

0.0021

|

Z

|

|

10

GHz/23℃

2.5 GHz/23℃

|

IPC-TM-650

2.5.5.5

|

|

Thermal Coefficient of ε

|

+40

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650

2.5.5.5

|

|

Volume Resistivity

|

1.7 x 1010

|

|

MΩ.cm

|

COND A

|

IPC-TM-650

2.5.17.1

|

|

Surface Resistivity

|

4.2 x 109

|

|

MΩ

|

COND A

|

IPC-TM-650

2.5.17.1

|

|

Electrical Strength

|

31.2(780)

|

Z

|

Kv/mm(v/mil)

|

0.51mm(0.020")

|

IPC-TM-650

2.5.6.2

|

|

Tensile Modulus

|

19,650(2,850)

19,450(2,821)

|

X

Y

|

MPa(ksi)

|

RT

|

ASTM

D 638

|

|

Tensile Strength

|

139(20.2)

100(14.5)

|

X

Y

|

MPa(ksi)

|

RT

|

ASTM

D 638

|

|

Flexural Strength

|

276

(40)

|

|

MPa

(kpsi)

|

|

IPC-TM-650

2.4.4

|

|

Dimensional Stability

|

<0.3

|

X,Y

|

mm/m

(mil/inch)

|

after etch+E2/150℃

|

IPC-TM-650

2.4.39A

|

|

Coefficient of Thermal Expansion

|

11

14

46

|

X

Y

Z

|

ppm/℃

|

-55℃to288℃

|

IPC-TM-650

2.4.41

|

|

Tg

|

>280

|

|

℃TMA

|

A

|

IPC-TM-650

2.4.24.3

|

|

Td

|

425

|

|

℃TGA

|

|

ASTM

D 3850

|

|

Thermal Conductivity

|

0.71

|

|

W/M/oK

|

80℃

|

ASTM

C518

|

|

Moisture Absorption

|

0.06

|

|

%

|

48hrs

immersion 0.060"

sample Temperature 50℃

|

ASTM

D 570

|

|

Density

|

1.79

|

|

gm/cm3

|

23℃

|

ASTM

D 792

|

|

Copper Peel Stength

|

1.05

(6.0)

|

|

N/mm

(pli)

|

after

solder float 1 oz.

EDC Foil

|

IPC-TM-650

2.4.8

|

|

Flammability

|

N/A

|

|

|

|

UL

94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com