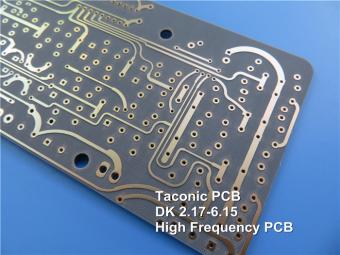

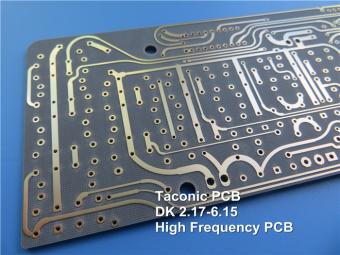

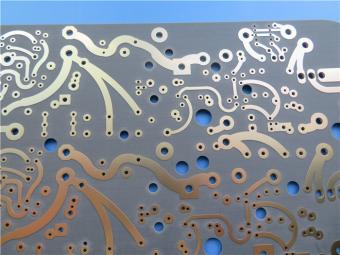

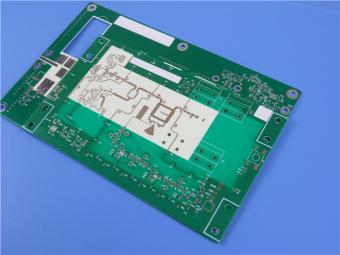

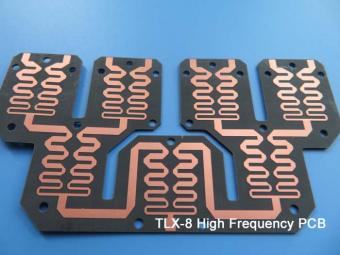

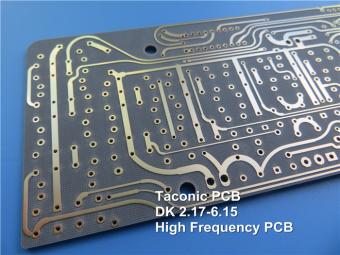

Taconic High Frequency PCB Built On TLY-3 30mil 0.762mm With Immersion Gold for Satellite / Cellular Communications

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Taconic TLY laminates are a type of low loss laminates. The woven matrix yields a more mechanically stable laminate that is suitable for high volume manufacturing. The low dissipation factor enables successful deployment for automotive radar applications designed at 77 GHz as well as other antennas in millimeter wave frequencies.

The dielectric constant is as low as 2.17-2.20 +/-0.02, and dissipation factor is as low as 0.0009.

Benefits:

Dimensionally stable

Lowest DF

Low moisture absorption

High copper peel strength

Uniform & consistent DK

Laser ablatable

Applications:

Automotive radar

Satellite/cellular communications

Power amplifiers

LNBs, LNAs, LNCs

Aerospace

Ka, E and W band applications

PCB Specifications:

|

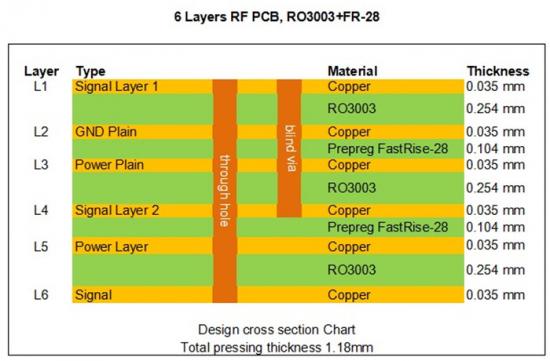

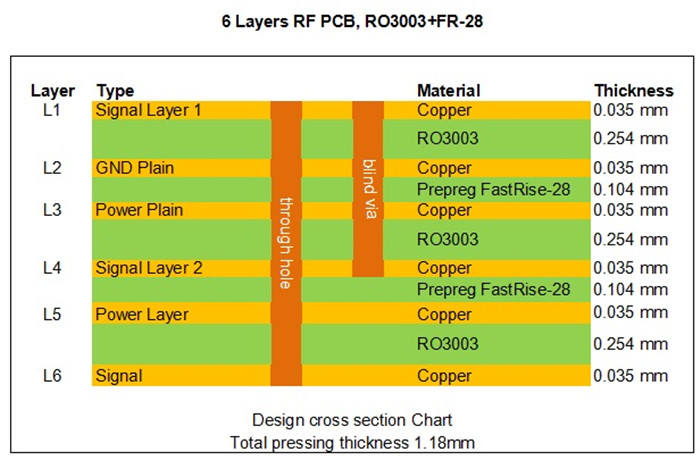

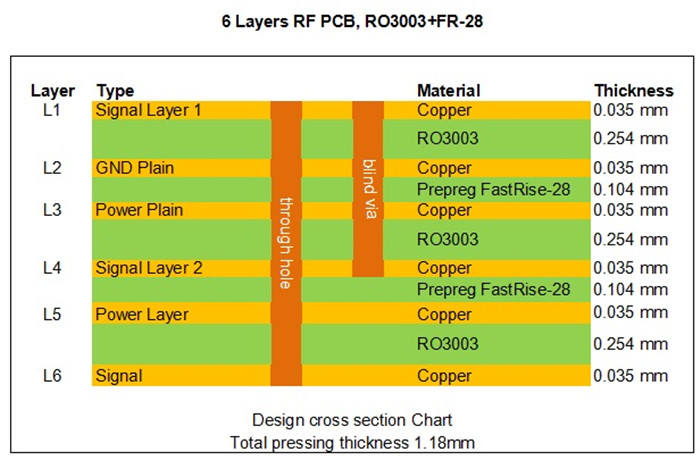

FastRise-28

(FR-28) Typical Value

|

|

Property

|

Value

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric

Constant,ε

|

2.78

|

-

|

-

|

10 GHz

|

IPC-TM-650

2.5.5.5.1

|

|

Dissipation Factor,tanδ

|

0.0015

|

-

|

-

|

10 GHz

|

IPC-TM-650 2.5.5.5.1

|

|

Water Absorption

|

0.08

|

|

%

|

|

IPC TM-650 2.6.2.1

|

|

Dielectric breakdown voltage

|

49

|

|

KV

|

|

IPC TM-650 2.5.6

|

|

Dielectric strength

|

1090

|

|

V/mil

|

|

ASTM D 149

|

|

Volume Resistivity

|

8.00

x 108

|

|

MΩ/cm

|

|

IPC-TM-650 2.5.17.1

|

|

Surface Resistivity

|

3.48

x 108

|

|

MΩ

|

|

IPC-TM-650 2.5.17.1

|

|

Tg

|

188

|

|

℃

|

|

ASTM E 1640

|

|

Tensil strength

|

1690

|

X

|

psi

|

|

ASTM D 882

|

|

1480

|

Y

|

psi

|

|

Tensil modulus

|

304

|

X

|

psi

|

|

ASTM D 882

|

|

295

|

Y

|

psi

|

|

Density

|

1.82

|

|

gm/cm³

|

|

ASTM D-792 Method A

|

|

Td

|

709

|

|

°F

|

|

IPC TM-650 2.4.24.6

|

|

Peel Strength

|

7

|

|

lbs/in

|

|

IPC-TM-650 2.4.8

|

|

Thermal Conductivity

|

0.25

|

|

W/mk

|

|

ASTM F433

|

Coefficient of Thermal Expansion

|

59

70

72

|

X

Y

Z

|

ppm/℃

|

|

IPC-TM-650

2.4.41

|

|

Hardness

|

68

|

|

Shore D

|

|

ASTM D 2240

|

|

RO3003 Typical Value

|

|

Property

|

RO3003

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.0±0.04

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5 Clamped Stripline

|

|

Dielectric

Constant,εDesign

|

3

|

Z

|

|

8GHz to 40 GHz

|

Differential Phase

Length Method

|

|

Dissipation

Factor,tanδ

|

0.001

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal

Coefficient of ε

|

-3

|

Z

|

ppm/℃

|

10

GHz -50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Dimensional

Stability

|

0.06

0.07

|

X

Y

|

mm/m

|

COND A

|

IPC-TM-650 2.2.4

|

|

Volume

Resistivity

|

107

|

|

MΩ.cm

|

COND A

|

IPC 2.5.17.1

|

|

Surface

Resistivity

|

107

|

|

MΩ

|

COND A

|

IPC 2.5.17.1

|

|

Tensile

Modulus

|

930

823

|

X

Y

|

MPa

|

23℃

|

ASTM D 638

|

|

Moisture

Absorption

|

0.04

|

|

%

|

D48/50

|

IPC-TM-650 2.6.2.1

|

|

Specific Heat

|

0.9

|

|

j/g/k

|

|

Calculated

|

|

Thermal

Conductivity

|

0.5

|

|

W/M/K

|

50℃

|

ASTM D 5470

|

Coefficient of Thermal Expansion

(-55 to 288℃)

|

17

16

25

|

X

Y

Z

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650 2.4.4.1

|

|

Td

|

500

|

|

℃TGA

|

|

ASTM D 3850

|

|

Density

|

2.1

|

|

gm/cm3

|

23℃

|

ASTM D 792

|

|

Copper Peel

Stength

|

12.7

|

|

Ib/in.

|

1oz,EDC After Solder

Float

|

IPC-TM 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free

Process Compatible

|

Yes

|

|

|

|

|

|

FastRise Prepreg

|

|

|

|

|

|

|

|

|

|

|

Product

|

Carrier

film (mil)

|

Film

Elognation (%)

|

Pressed

Thickness (mil)

|

Pressed

Thickness (mil)

|

Pressed

Thickness (mil)

|

Nominal DK (Min. / Max.) (10 GHz)

|

Typical Flow (%)

|

|

FR-26-0025-60

|

1

|

200-300

|

2.7

|

1.3

|

1

|

2.58

|

17

|

|

FR-27-0030-25

|

2.3

|

30-60

|

3.5

|

2.1

|

Not

recommended

|

2.74 (2.71 / 2.78)

|

4

|

|

FR-27-0035-66

|

1

|

200-300

|

3.7

|

2.5

|

2.1

|

2.7

|

36

|

|

FR-27-0040-25

|

3

|

30-60

|

4.9

|

3.7

|

Not

recommended

|

2.74

|

4

|

|

FR-28-0040-50

|

1

|

200-300

|

4.9

|

3.7

|

3.5

|

2.81 (2.80 / 2.82)

|

23

|

|

FR-27-0042-75

|

2.3

|

30-60

|

5.16

|

3.96

|

3.5

|

2.73

|

35

|

|

FR-27-0045-35

|

3

|

30-60

|

5.8

|

4.6

|

4.2

|

2.75 (2.73 / 2.77)

|

13

|

|

FR-27-0050-40

|

3

|

30-60

|

6.1

|

5.5

|

4.9

|

2.76 (2.71 /

2.80)

|

23

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 oz Cu. 50%

removal

|

1 oz. Cu. 50%

removal

|

|

|

|

|

|

|

|

|

|

|

|

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com