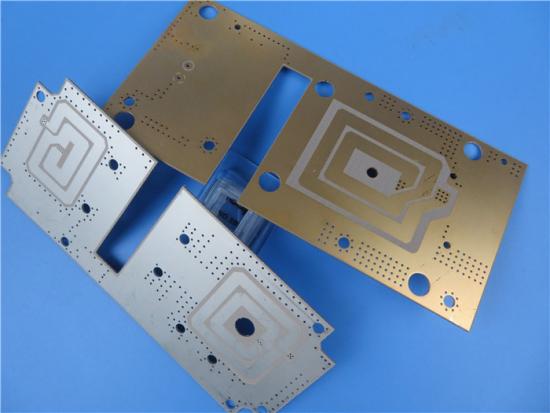

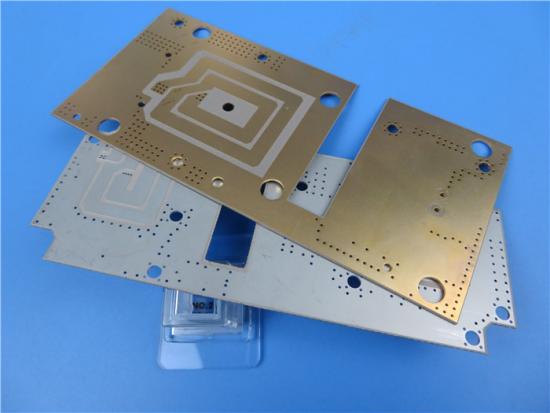

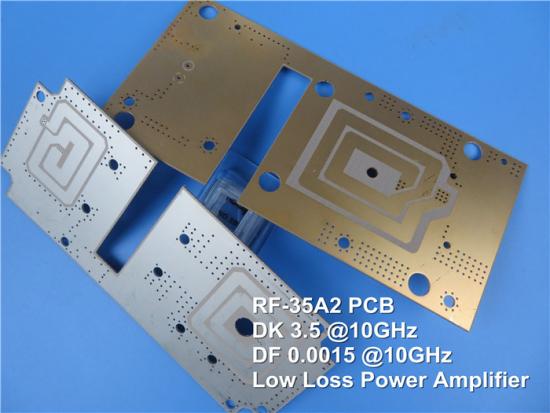

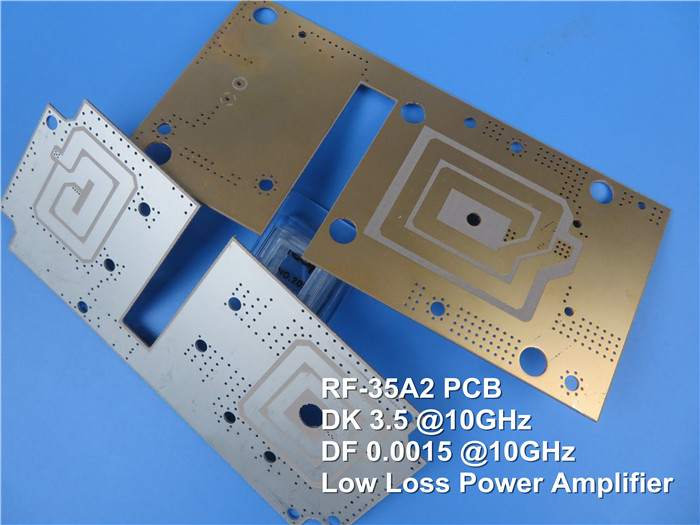

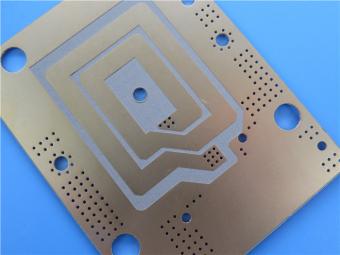

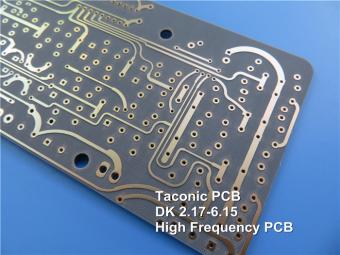

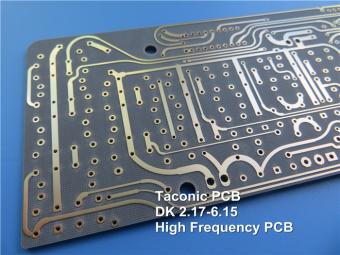

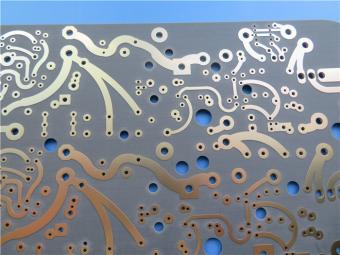

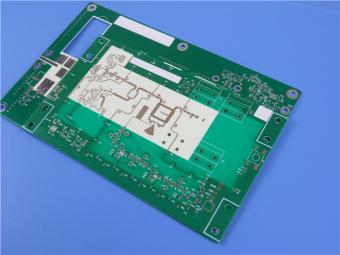

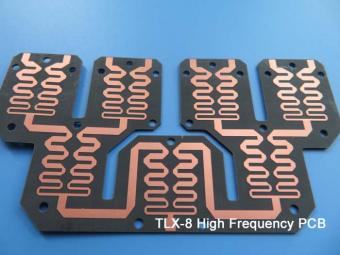

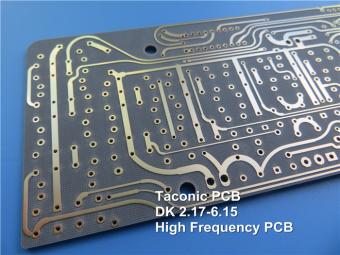

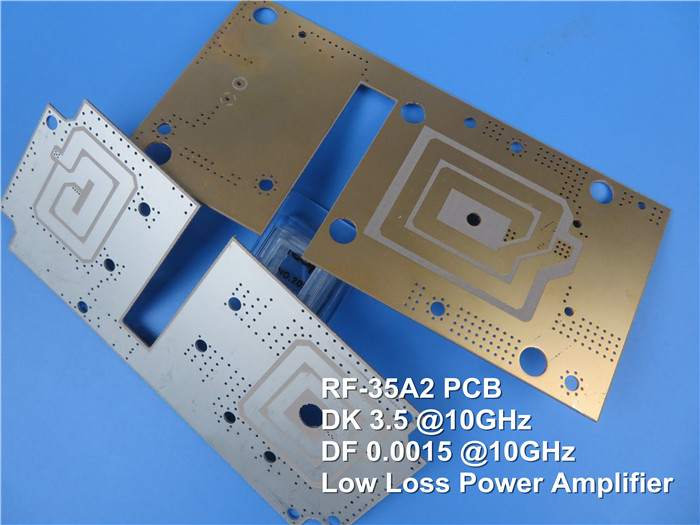

Taconic RF-35A2 PCB 20mil (0.508 mm) 30mil(0.762mm) 60mil (1.524mm) With Immersion Gold Immersion Silver and Blue Mask

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Taconic’s RF-35A2 substrate is designed to have ultra-low fiberglass content to achieve "best in class" insertion loss properties and the uniform dielectric constant 3.5 +/-0.05 throughout the laminate. It is a type of ultra low loss power amplifier material.

RF-35A2 is manufactured with a proprietary multi-step process with excellent dielectric performance and excellent copper peel adhesion.The low 0.0015 dissipation factor at 10 GHz allows for maximum power transfer resulting in low heat generation.

Benefits:

Low loss properties

DK tolerance of +/- 0.05

Homogeneous DK

Excellent peel strength

Low moisture absorption

Our PCB Capability (RF-35A2):

|

PCB Capability (RF-35A2)

|

|

PCB Material:

|

PTFE Ceramic

Fiberglass

|

|

Designation:

|

RF-35A2

|

|

Dielectric constant:

|

3.15

|

|

Dissipation Factor

|

0.0015

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm)

|

|

PCB thickness:

|

10mil (0.254mm); 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, Immersion silver, Immersion tin, OSP etc..

|

Applications:

Power amplifiers

Filters / couplers

High speed digital

Passive components

Wireless antennas

RF-35A2 Typical Values:

|

RF-35A2

Typical Values

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

Dk @ 10 GHz

|

IPC-650 2.5.5.5.1(Modified)

|

|

3.5

|

|

3.5

|

|

Df @ 10 GHz

|

IPC-650 2.5.5.5.1(Modified)

|

|

0.0015

|

|

0.0015

|

|

Moisture Absorption

|

IPC-650 2.6.2.1

|

%

|

0.03

|

%

|

0.03

|

|

Dielectric Breakdown

|

IPC-650 2.5.6/ASTM D

149

|

kV

|

59

|

kV

|

59

|

|

Dielectric Strength

|

ASTM D 149

|

V/mil

|

1000

|

V/mm

|

39,370

|

|

Volume Resistivity

|

IPC-650 2.5.17.1 Sec.

5.2.1(Humidity Cond.)

|

Mohm/cm

|

10^9

|

Mohm/cm

|

10^9

|

|

Surface Resistivity

|

IPC-650 2.5.17.1 Sec.

5.2.1(Humidity Cond.)

|

Mohm

|

10^8

|

Mohm

|

10^8

|

|

Arc Resistance

|

IPC-650 2.5.1

|

Seconds

|

242

|

Seconds

|

242

|

|

Flexural Strength(MD)

|

IPC-650 2.4.4

|

kpsi

|

24

|

N/mm2

|

165

|

|

Flexural Strength(CD)

|

IPC-650 2.4.4

|

kpsi

|

15

|

N/mm2

|

103

|

|

Tensile Strength(MD)

|

ASTM D 3039

|

psi

|

16,800

|

N/mm2

|

116

|

|

Tensile Strength(CD)

|

ASTM D 3039

|

psi

|

11,000

|

N/mm2

|

75.8

|

|

Young’s Modulus(MD)

|

ASTM D 3039

|

psi

|

106

|

N/mm2

|

8,343

|

|

Young’s Modulus(CD)

|

ASTM D 3039

|

psi

|

106

|

N/mm2

|

7,171

|

|

Poisson’s Ratio(MD)

|

ASTM D 3039

|

|

0.14

|

|

0.14

|

|

Poisson’s Ratio(CD)

|

ASTM D 3039

|

|

0.1

|

|

0.1

|

|

Strain at Break(MD)

|

ASTM D 3039

|

%

|

1.6

|

%

|

1.6

|

|

Strain at Break(CD)

|

ASTM D 3039

|

%

|

1.4

|

%

|

1.4

|

|

Compressive Modulus (Z

axis)

|

ASTM D 695(23°C)

|

kpsi

|

385

|

N/mm2

|

2,650

|

|

Peel Strength(1 oz. VLP)

|

IPC-650 2.4.8(Thermal Stress)

|

lbs/in

|

12

|

N/mm

|

2.1

|

|

Peel Strength(1 oz. VLP)

|

IPC-650 2.4.8.3 (150°C )(Elevated

Temp.)

|

lbs/in

|

14

|

N/mm

|

2.5

|

|

Peel Strength(1 oz. VLP)

|

IPC-650 2.4.8 Sec.

5.2.3(Proc. Chemicals)

|

lbs/in

|

11

|

N/mm

|

2

|

|

Density(Specific Gravity)

|

|

gm/cm3

|

2.28

|

gm/cm3

|

2.28

|

|

Specific Heat

|

ASTM E 1269 (DSC)(100°C)

|

J/g/K

|

0.99

|

J/g/K

|

0.99

|

|

Thermal Conductivity

|

ASTM F 433

|

W/M*K

|

0.29

|

W/M*K

|

0.29

|

|

Td

|

IPC-650 2.4.24.6 2% Weight Loss

|

°C

|

528

|

°C

|

528

|

|

Td

|

IPC-650 2.4.24.65% Weight Loss

|

°C

|

547

|

°C

|

547

|

|

CTE (x)

|

IPC-650 2.4.41 (>RT - 125°C)

|

ppm/°C

|

10

|

ppm/°C

|

10

|

|

CTE (y)

|

IPC-650 2.4.41(>RT - 125°C)

|

ppm/°C

|

13

|

ppm/°C

|

13

|

|

CTE (z)

|

IPC-650 2.4.41(>RT - 125°C)

|

ppm/°C

|

108

|

ppm/°C

|

108

|

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com