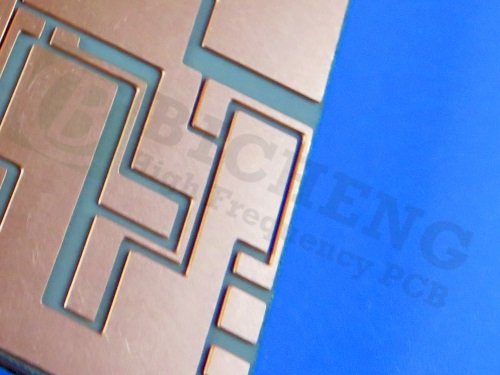

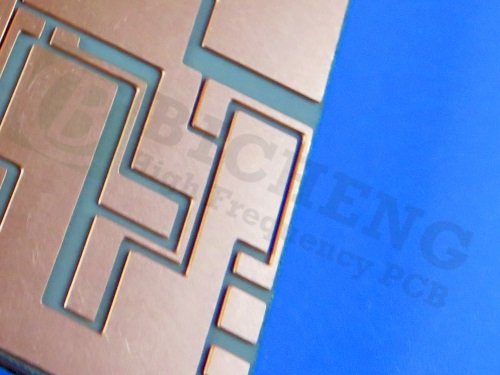

10 OZ Heavy Copper TU-865 High TG Material Double Sided PCB with ENIG

The TU-865 PCB is a state-of-the-art, 2-layer printed circuit board designed to meet the rigorous demands of modern electronics. Built with TU-865 material, a high-performance, halogen-free laminate, this PCB is engineered for applications requiring exceptional thermal stability, electrical performance, and environmental resilience. Whether you're working on automotive systems, telecommunications infrastructure, or industrial equipment, the TU-865 PCB delivers unmatched reliability and performance.

Key Specifications

|

Category

|

Specification

|

|

Board Type

|

2 layers

|

|

Material Type

|

TU-865

|

|

Solder Mask

|

Both sides, Green

|

|

Silkscreen Print

|

Top side, White

|

|

Surface Finish

|

ENIG

|

|

Total Board Thickness

|

3.0mm +/- 10%

|

|

Board Size

|

120mm x 210mm = 1 PCS

|

|

Minimum Hole Size

|

0.4mm

|

|

Solder Mask Thickness

|

100um

|

|

Minimum Trace Width

|

600um

|

|

Minimum Spacing

|

600um

|

TU-865 Material: The Foundation of Excellence

The TU-865 PCB is constructed using TU-865 Tg200 material, a high-performance PCB laminate made from epoxy resin and E-glass fabric. Thishigh tgmaterial is specifically designed for applications requiring high reliability, superior electrical performance, and resistance to harsh environments. Key features of TU-865 material include:

1. High Glass Transition Temperature (Tg):

Tg (DSC): 200°C

Tg (TMA): 185°C

This ensures excellent thermal stability, making the PCB suitable for high-temperature applications.

2. Low Dielectric Constant and Dissipation Factor:

Dielectric Constant: 4.4 @ 10GHz

Dissipation Factor: 0.014 @ 10GHz

These properties ensure superior signal integrity, making the TU-865 substrate PCB ideal for high-frequency applications.

3. Environmental and Safety Compliance:

Halogen-free material, compliant with UL94V-0 flammability standards.

Lead-free processing compatible, aligning with RoHS and WEEE directives.

4. Exceptional Durability:

Low coefficient of thermal expansion (CTE) for reduced stress during thermal cycling.

Moisture resistance of 0.13%, ensuring reliability in humid environments.

Anti-CAF (Conductive Anodic Filament) capability, preventing electrical failures.

PCB Stack-Up and Construction

The TU-865 PCB features a robust 2-layer stack-up designed for optimal performance:

|

Material

|

Copper Layer

|

Thickness (µm)

|

Specification

|

|

COPPER

|

1

|

350

|

-

|

|

TU-865

|

Core

|

3000

|

IPC-4101/24

|

|

COPPER

|

2

|

350

|

-

|

PCB Statistics and Design Features

|

Category

|

Count

|

|

Components

|

38

|

|

Total Pads

|

98

|

|

Thru Hole Pads

|

35

|

|

Top SMT Pads

|

26

|

|

Bottom SMT Pads

|

12

|

|

Vias

|

52

|

|

Nets

|

2

|

The TU-865 laminate PCB is designed with precision, offering a balance of functionality and manufacturability. Its ENIG surface finish provides excellent solderability and corrosion resistance, while the green solder mask and white silkscreen ensure clear component placement and identification.

Key Features of the TU-865 PCB

1.High Thermal Stability:

With a Tg of 200°C, the TU-865 PCB can withstand extreme temperatures, making it ideal for automotive and industrial applications.

2.Superior Electrical Performance:

The low dielectric constant and dissipation factor ensure minimal signal loss, even at high frequencies.

3.Environmental Resilience:

Halogen-free and lead-free, the TU-865 PCB is environmentally friendly and complies with global regulations.

4.Moisture and Chemical Resistance:

The material's low moisture absorption and chemical resistance make it suitable for harsh environments.

5.Anti-CAF Capability:

Prevents electrical failures caused by conductive anodic filament formation, enhancing long-term reliability.

6.Dimensional Stability:

The low CTE ensures minimal expansion and contraction during thermal cycling, reducing stress on components.

Typical Applications

The TU-865 PCB is versatile and well-suited for a wide range of demanding applications, including:

1.Automotive Electronics:

Engine control units, sensors, and infotainment systems that require high reliability and thermal stability.

2.Telecommunications:

Base stations, servers, and networking equipment that demand superior signal integrity and durability.

3.Industrial Equipment:

Control systems, power supplies, and automation devices operating in harsh environments.

4.Harsh Environment Applications:

Aerospace, military, and outdoor electronics that require resistance to extreme temperatures, moisture, and chemicals.

Why Choose the TU-865 PCB?

1.Reliability:

Designed for high-reliability applications, the TU-865 PCB ensures consistent performance under challenging conditions.

2.Performance:

With excellent electrical and thermal properties, this PCB is ideal for high-frequency and high-temperature applications.

3.Sustainability:

The halogen-free, lead-free construction aligns with environmental regulations and reduces hazardous waste.

4.Global Availability:

The TU-865 PCB is available worldwide, ensuring quick delivery and support for your projects.

Conclusion

The 10oz heavy copper TU-865 PCB is a premium solution for engineers and designers seeking a high-performance, reliable, and environmentally friendly PCB. With its advanced material properties, robust construction, and versatility, the TU-865 PCB is the ideal choice for automotive, telecommunications, industrial, and harsh environment applications. Whether you're developing cutting-edge technology or upgrading existing systems, the TU-865 10oz heavy copper PCB delivers the performance and reliability you need to succeed.

Explore the possibilities with the TU-865 PCB–your partner in innovation and reliability. Contact us today to learn more or place your order!

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com