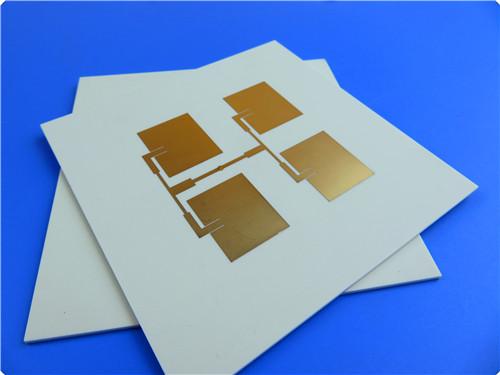

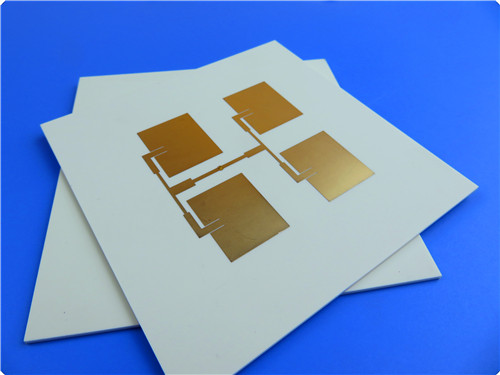

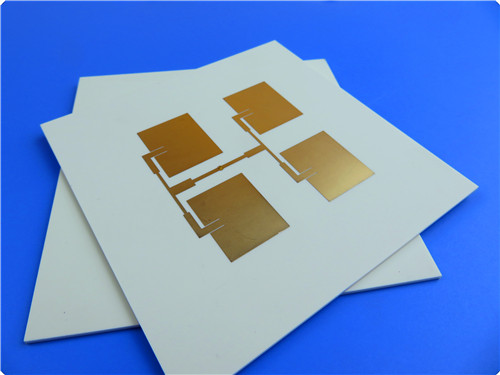

Alumina AL2O3 96% Ceramic PCB - Double-Layer Board-1mm Thickness-Immersion Gold

Introduction

In the ever-evolving world of electronics, the demand for high-performance, durable, and reliable printed circuit boards (PCBs) is on the rise. The AL2O3 96% Ceramic PCB is a cutting-edge solution designed to meet the rigorous demands of modern electronic applications. This double-layer, 1mm thick ceramic PCB with immersion gold surface finish is engineered to deliver exceptional performance in high-temperature, high-frequency, and high-power environments. Whether you're in aerospace, automotive, energy, IoT, or medical industries, this ceramic PCB is your go-to solution for ensuring stability, efficiency, and longevity in your electronic devices.

PCB Construction details

|

Parameter

|

Details

|

|

Base Material

|

AL2O3 (96%) Ceramic Substrate

|

|

Layer Count

|

Double-Sided

|

|

Board Dimensions

|

100mm x 100mm = 1PCS, ±0.15mm

|

|

Minimum Trace/Space

|

5/6 mils

|

|

Minimum Hole Size

|

0.4mm

|

|

Blind Vias

|

No

|

|

Finished Board Thickness

|

1.1mm

|

|

Finished Cu Weight

|

1oz (1.4 mils) outer layers

|

|

Via Plating Thickness

|

20µm

|

|

Surface Finish

|

Immersion Gold

|

|

Top Silkscreen

|

No

|

|

Bottom Silkscreen

|

No

|

|

Top Solder Mask

|

No

|

|

Bottom Solder Mask

|

No

|

|

Electrical Test

|

100% tested prior to shipment

|

PCB Stackup

Copper Layer 1: 35µm

Ceramic AL2O3 96%: 1.0mm

Copper Layer 2: 35µm

PCB Statistics

|

PCB Statistic

|

Count

|

|

Components

|

16

|

|

Total Pads

|

33

|

|

Thru Hole Pads

|

25

|

|

Top SMT Pads

|

17

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

22

|

|

Nets

|

2

|

Accepted Standards

Artwork Supplied: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability

This product is available worldwide, ensuring that no matter where you are, you can access this high-quality ceramic PCB for your projects.

Typical Applications

1.Aerospace:

The AL2O3 96% Ceramic PCB is the preferred choice for spacecraft, satellites, and aviation electronic devices due to its outstanding high-temperature resistance and radiation tolerance. These characteristics ensure the stable operation of electronic equipment in extreme environments, providing solid technical support for aerospace exploration.

2.Automotive Electronics:

In the automotive sector, ceramic PCBs demonstrate their high-temperature resistance, shock resistance, and corrosion resistance. They are widely applied in automotive electronic control units, engine control systems, and safety systems. This stability ensures that automotive electronic devices can operate efficiently even in harsh conditions, significantly enhancing the safety and reliability of vehicles.

3.Energy Sector:

The energy sector also relies heavily on ceramic PCBs. In energy devices such as solar panels, wind power generation equipment, and power inverters, ceramic PCBs provide stable electronic support, ensuring the efficient operation and long-term stability of energy devices. This provides robust technical support for the development and utilization of sustainable energy sources.

4.IoT Devices:

With the rapid development of IoT technology, the demand for miniaturization, high performance, and durability of IoT devices is increasing. Ceramic PCBs, with their unique advantages, have become the ideal choice for IoT devices. Applied in smart homes, smart health, smart transportation, and other fields, they drive the further popularization and development of IoT technology.

5.High-Power Electronic Devices:

Ceramic PCBs play a crucial role in high-power electronic devices, RF and microwave circuits, industrial applications in high-temperature environments, medical equipment, LED lighting modules, the chemical industry, and more. They provide stable electronic support for electronic devices in these sectors, driving the development and progress of related industries.

Introduction of AL2O3 96% Ceramic Material

AL2O3 ceramic laminates PCB mainly consist of aluminum oxide (Al2O3), typically comprising over 96% of the composition. Additionally, small quantities of other elements such as yttrium oxide (Y2O3), magnesium oxide (MgO), among others, are incorporated to enhance the ceramic laminates' performance.

-Density: 3.5-3.9 g/cm³

-Hardness: Exceeds 9 on the Mohs scale

-Thermal Conductivity: 20-30 W/(m·K)

-Coefficient of Linear Expansion: 6-8×10^-6/°C

Features

Density: 3.7 g/cm³

Warpage: ≤2

Surface Roughness: 0.2-0.75 µm

Thermal Conductivity: 24 W/m·K

Coefficient of Linear Expansion: 6.5-8.0 × 10^-6/K

Dielectric Constant at 1MHz: 9-10

Breaking Voltage: 17 KV/mm

Volume Resistivity: 10^14 Ω·cm

Flexural Strength: 350 MPa

Benefits

1.High Resistance: Reduces current loss and heat generation.

2.Outstanding High-Frequency Performance: Suitable for high-frequency communication and signal processing applications.

3.High Thermal Conductivity: Effective heat dissipation to prevent overheating.

4.Excellent Chemical Stability: Resistant to chemical corrosion, ensuring long-term stability.

5.Mechanical Strength: Resistant to vibration, high temperatures, and high pressure.

6.Precision of Internal Circuits: Maintains high precision and stability during manufacturing.

7.High Current-Carrying Capacity: Handles large currents with minimal temperature rise.

8.Excellent Heat Dissipation: Low thermal expansion coefficient and shape stability enhance heat dissipation.

9.Outstanding Insulation Performance: Provides high voltage resistance, ensuring safety.

10.Strong Bonding: Firm bonding between copper foil and ceramic substrate prevents delamination.

Conclusion

The AL2O3 96% Alumina Ceramic substrate PCB is a versatile and robust solution designed to meet the demanding requirements of various high-performance applications. Its exceptional thermal conductivity, mechanical strength, and chemical stability make it an ideal choice for industries ranging from aerospace to IoT. With its high resistance, precision, and durability, this Alumina oxide PCB ensures the reliable operation of your electronic devices in even the most challenging environments. Choose the AL2O3 96% Ceramic PCB for your next project and experience the difference in performance and reliability.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com