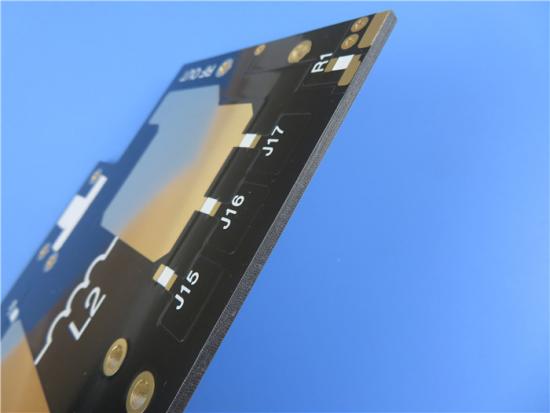

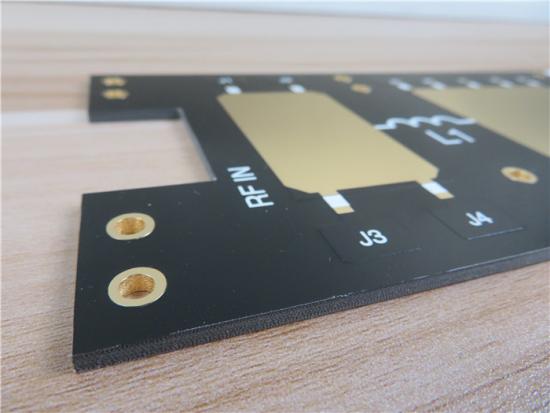

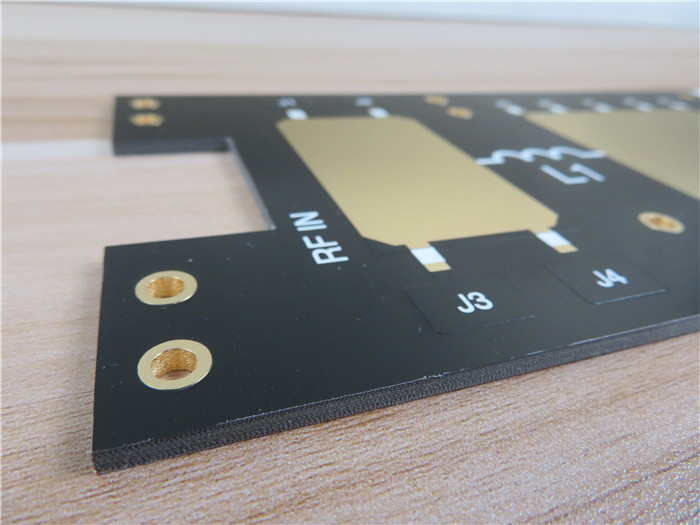

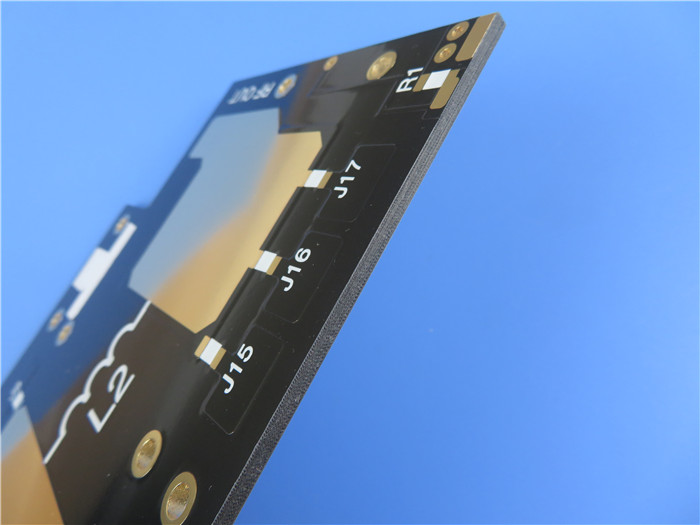

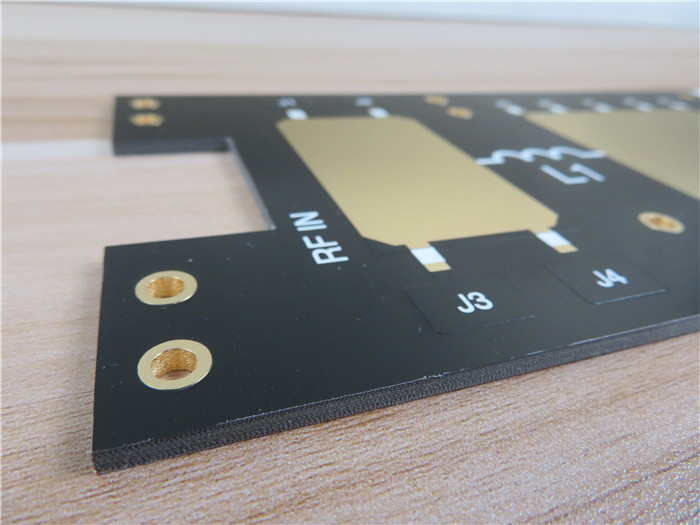

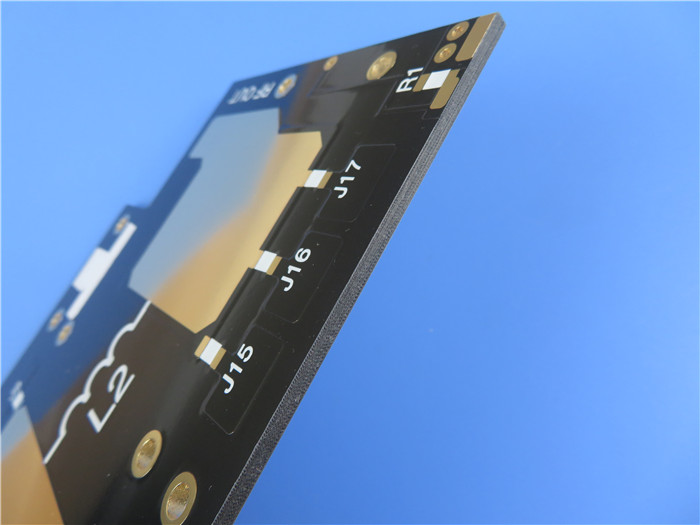

F4BTMS1000 High Frequency PCB High DK10.2 PTFE 3.2mm F4BTMS Series Substrates with Immersion Gold

(PCB's are custom-made products, the picture and parameters shown are just for reference)

Brief Introduction

This Double-sided F4BTMS1000 PCB features circuitry on both the top and bottom layers, each with a copper weight of 2oz. The middle layer consists of an F4BTMS1000 core material, measuring 3.175 mm in thickness. The High DK10.2 PTFE PCB size is 215mm x 145mm, with a single unit in the panel. It is equipped with surface mount components and does not include any through-hole components. The surface finish is Immersion Gold, and a black solder mask is applied to the top side of the F4BTMS PCB. Prior to shipment, a comprehensive 100% Electrical Test is carried out to ensure functionality and uphold quality standards.

Here are the details in table below.

|

PCB SIZE

|

215 x 145mm=1PCS

|

|

BOARD TYPE

|

Double sided PCB

|

|

Number of Layers

|

2 layers

|

|

Surface Mount Components

|

YES

|

|

Through Hole Components

|

NO

|

|

LAYER STACKUP

|

copper ------- 70 um(1 oz+plate) TOP layer

|

|

F4BTMS1000 -3.175 mm

|

|

copper ------- 70 um(1 oz + plate) BOT Layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

12 mil / 12 mil

|

|

Minimum / Maximum Holes:

|

0.6 mm / 3.0 mm

|

|

Number of Different Holes:

|

6

|

|

Number of Drill Holes:

|

36

|

|

Number of Milled Slots:

|

1

|

|

Number of Internal Cutouts:

|

0

|

|

Impedance Control:

|

no

|

|

Number of Gold finger:

|

0

|

|

BOARD MATERIAL

|

|

|

Glass Epoxy:

|

F4BTMS1000 Dk10.2

|

|

Final foil external:

|

2oz

|

|

Final foil internal:

|

N/A

|

|

Final height of PCB:

|

3.2 mm ±10%

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

Immersion Gold

|

|

Solder Mask Apply To:

|

Top, Black

|

|

Solder Mask Color:

|

no

|

|

Solder Mask Type:

|

no

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of Component Legend

|

Top

|

|

Colour of Component Legend

|

White

|

|

Manufacturer Name or Logo:

|

Marked on the board in a conductor and leged FREE AREA

|

|

VIA

|

Plated through hole(PTH), minimum size 0.6mm.

|

|

FLAMIBILITY RATING

|

UL 94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline dimension:

|

0.0059"

|

|

Board plating:

|

0.0029"

|

|

Drill tolerance:

|

0.002"

|

|

TEST

|

100% Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide, Globally.

|

F4BTMS High Frequency Laminate

The F4BTMS series materials are upgraded version of the F4BTM series materials. Building upon its foundation, significant technological advancements have been made in material formulation and manufacturing processes. The F4B material now incorporates a large amount of ceramics and utilizes ultra-thin and ultra-fine fiberglass cloth reinforcement. These enhancements have greatly improved the material's performance, resulting in a wider range of dielectric constants. It is a high-reliability material suitable for aerospace applications, capable of replacing similar foreign products.

By incorporating a small amount of ultra-thin and ultra-fine fiberglass cloth reinforcement, along with a significant and uniform mixture of special nanoceramics and polytetrafluoroethylene resin, the fiberglass effect during the propagation of electromagnetic waves is minimized, reducing dielectric loss and enhancing dimensional stability. The F4B substrate exhibits reduced anisotropy in the X/Y/Z directions, allowing for higher frequency usage, increased electrical strength, and improved thermal conductivity. The material also possesses excellent low coefficient of thermal expansion and stable dielectric temperature characteristics.

The F4BTMS series comes standard with RTF low roughness copper foil, which not only reduces conductor loss but also provides excellent peel strength. It can be paired with copper-based or aluminum-based options.

Features

◆ Small dielectric constant tolerance and good consistency between batches;

◆ Ultra-low dielectric loss;

◆ It has stable dielectric constant and low loss value when the operating frequency is within 40G, which can meet the phase-sensitive application;

◆ The change coefficient of dielectric constant and dielectric loss with temperature is excellent, maintaining excellent frequency stability and phase stability between - 55 ℃ and 150 ℃;

◆ Excellent radiation resistance. After the dose irradiation treatment, it still maintains stable dielectric and physical properties.

◆ Low exhaust performance, tested according to the standard method of material volatilization performance under vacuum conditions, meets the requirements of vacuum exhaust for aerospace;

◆ The thermal expansion coefficient of material in X/Y/Z direction is small; The dimensional thermal stability and the reliability of pore copper are guaranteed;

◆ Better thermal conductivity, suitable for high-power applications.

◆ Excellent dimensional stability;

◆ Low water absorption.

Typical Applications

-Aerospace equipment, space and cabin equipment

- Microwave and RF

- Radar and military radar

- Feed network

- Phase-sensitive antenna and phased array antenna

- Satellite communication, etc

Data Sheet(F4BTMS)

|

Product Technical Parameters

|

Product Models & Data Sheet

|

|

Product Features

|

Test Conditions

|

Unit

|

F4BTMS220

|

F4BTMS233

|

F4BTMS255

|

F4BTMS265

|

F4BTMS294

|

F4BTMS300

|

F4BTMS350

|

F4BTMS430

|

F4BTMS450

|

F4BTMS615

|

F4BTMS1000

|

|

Dielectric Constant (Typical)

|

10GHz

|

/

|

2.2

|

2.33

|

2.55

|

2.65

|

2.94

|

3.00

|

3.50

|

4.30

|

4.50

|

6.15

|

10.20

|

|

Dielectric Constant Tolerance

|

/

|

/

|

±0.02

|

±0.03

|

±0.04

|

±0.04

|

±0.04

|

±0.04

|

±0.05

|

±0.09

|

±0.09

|

±0.12

|

±0.2

|

|

Dielectric Constant (Design)

|

10GHz

|

/

|

2.2

|

2.33

|

2.55

|

2.65

|

2.94

|

3.0

|

3.50

|

4.3

|

4.5

|

6.15

|

10.2

|

|

Loss Tangent (Typical)

|

10GHz

|

/

|

0.0009

|

0.0010

|

0.0012

|

0.0012

|

0.0012

|

0.0013

|

0.0016

|

0.0015

|

0.0015

|

0.0020

|

0.0020

|

|

20GHz

|

/

|

0.0010

|

0.0011

|

0.0013

|

0.0014

|

0.0014

|

0.0015

|

0.0019

|

0.0019

|

0.0019

|

0.0023

|

0.0023

|

|

40GHz

|

/

|

0.0013

|

0.0015

|

0.0016

|

0.0018

|

0.0018

|

0.0019

|

0.0024

|

0.0024

|

0.0024

|

/

|

/

|

|

Dielectric Constant Temperature Coefficient

|

-55 º~150ºC

|

PPM/℃

|

-130

|

-122

|

-92

|

-88

|

-20

|

-20

|

-39

|

-60

|

-58

|

-96

|

-320

|

|

Peel Strength

|

1 OZ RTF copper

|

N/mm

|

>2.4

|

>2.4

|

>1.8

|

>1.8

|

>1.2

|

>1.2

|

>1.2

|

>1.2

|

>1.2

|

>1.2

|

>1.2

|

|

Volume Resistivity

|

Standard Condition

|

MΩ.cm

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

|

Surface Resistivity

|

Standard Condition

|

MΩ

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

≥1×10^8

|

|

Electrical Strength (Z direction)

|

5KW,500V/s

|

KV/mm

|

>26

|

>30

|

>32

|

>34

|

>40

|

>40

|

>42

|

>44

|

>45

|

>48

|

>23

|

|

Breakdown Voltage (XY direction)

|

5KW,500V/s

|

KV

|

>35

|

>38

|

>40

|

>42

|

>48

|

>52

|

>55

|

>52

|

>54

|

>55

|

>42

|

|

Coefficientof Thermal Expansion (X, Y direction)

|

-55 º~288ºC

|

ppm/ºC

|

40, 50

|

35, 40

|

15, 20

|

15, 20

|

10, 12

|

10, 11

|

10, 12

|

13, 12

|

12, 12

|

10, 12

|

16, 18

|

|

Coefficientof Thermal Expansion (Z direction)

|

-55 º~288ºC

|

ppm/ºC

|

290

|

220

|

80

|

72

|

22

|

22

|

20

|

47

|

45

|

40

|

32

|

|

Thermal Stress

|

260℃, 10s,3 times

|

/

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

0.02

|

0.02

|

0.025

|

0.025

|

0.02

|

0.025

|

0.03

|

0.08

|

0.08

|

0.1

|

0.03

|

|

Density

|

Room Temperature

|

g/cm3

|

2.18

|

2.22

|

2.26

|

2.26

|

2.25

|

2.28

|

2.3

|

2.51

|

2.53

|

2.75

|

3.2

|

|

Long-Term Operating Temperature

|

High-Low Temperature Chamber

|

℃

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

|

Thermal Conductivity

|

Z direction

|

W/(M.K)

|

0.26

|

0.28

|

0.31

|

0.36

|

0.58

|

0.58

|

0.6

|

0.63

|

0.64

|

0.67

|

0.81

|

|

Flammability

|

/

|

UL-94

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

|

Material Composition

|

/

|

/

|

PTFE,Ultra-thin and ultra-fine (quartz) fiberglass.

|

PTFE,Ultra-thin and ultra-fine fiberglass, ceramics.

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com