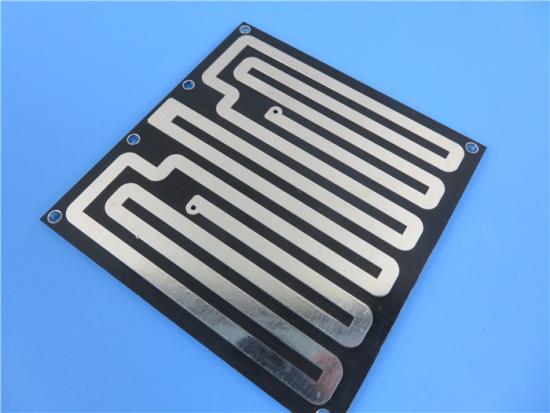

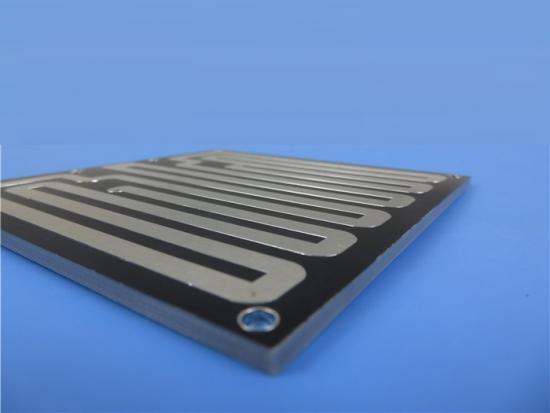

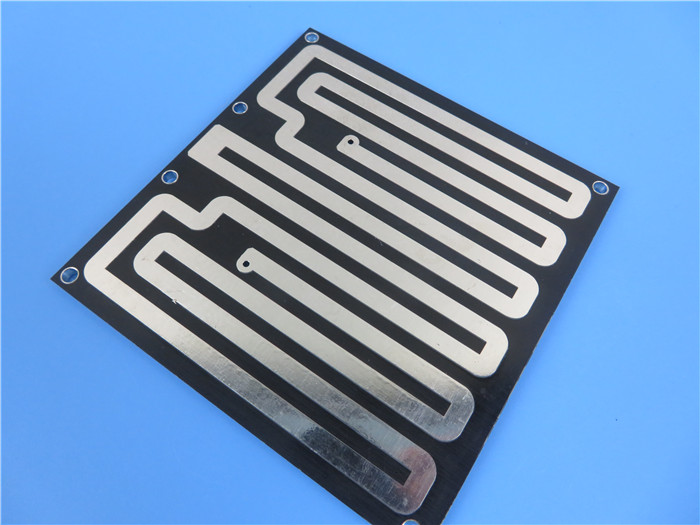

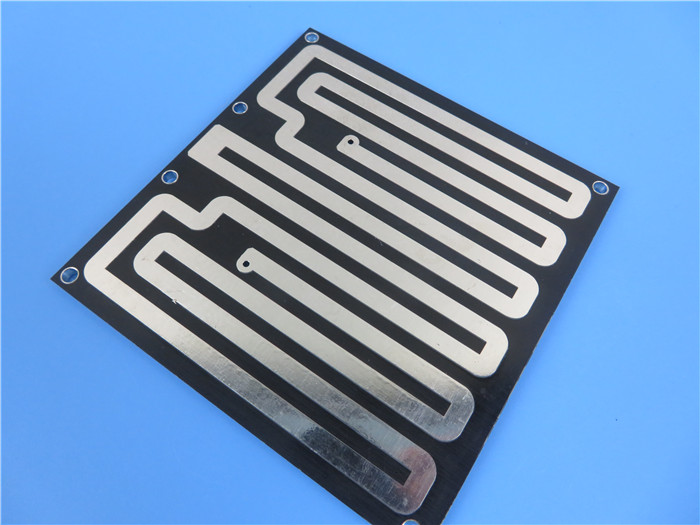

Wangling TP1020 High Frequency Printed Circuit Board DK10.2 5.0mm Alternative High DK RF PCB

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

General Description

This is a type of high frequency PCB which is built on TP1020 Wangling substrate (DK10.2 PCB). It is a double layer build up on 5.0mm laminate PCB. Surface finish is hot air soldering level (HASL) with black solder mask. Both layers are 1 oz copper finished.The boards are fabricated per IPC 6012 Class 2 using supplied Gerber data. Every 20 boards are packed for shipment.

PCB Specifications

|

PCB SIZE

|

50 x 61mm=1up

|

|

BOARD TYPE

|

Double sided PCB

|

|

Number of Layers

|

2 layers

|

|

Surface Mount Components

|

YES

|

|

Through Hole Components

|

NO

|

|

LAYER STACKUP

|

copper ------- 35um(0.5 oz+plate) TOP layer

|

|

TP1020 - 5.0mm

|

|

copper ------- 35um(0.5 oz + plate) BOT Layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

197 mil / 118 mil

|

|

Minimum / Maximum Holes:

|

2.0 mm / 6.0 mm

|

|

Number of Different Holes:

|

2

|

|

Number of Drill Holes:

|

8

|

|

Number of Milled Slots:

|

0

|

|

Number of Internal Cutouts:

|

0

|

|

Impedance Control:

|

no

|

|

Number of Gold finger:

|

0

|

|

BOARD MATERIAL

|

|

|

Glass Epoxy:

|

TP1020 DK 10.2

|

|

Final foil external:

|

1.0 oz

|

|

Final foil internal:

|

N/A

|

|

Final height of PCB:

|

5.1 mm ±0.12

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

HASL Lead free

|

|

Solder Mask Apply To:

|

Top layer

|

|

Solder Mask Color:

|

Black

|

|

Solder Mask Type:

|

LPI

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of Component Legend

|

N/A

|

|

Colour of Component Legend

|

N/A

|

|

Manufacturer Name or Logo:

|

N/A

|

|

VIA

|

Plated through hole(PTH), minimum size 2.0mm.

|

|

FLAMIBILITY RATING

|

94V-0

|

|

DIMENSION TOLERANCE

|

|

|

Outline dimension:

|

0.0059"

|

|

Board plating:

|

0.0029"

|

|

Drill tolerance:

|

0.002"

|

|

TEST

|

100% Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide, Globally.

|

TypicalApplications

1.Aircraft Collision Avoidance Systems

2.GPS Antennas

3.Microstrip Patch Antennas

4.Passive Components (filters, couplers, power dividers)

5.Satellite Components

TP-1/2 High Frequency Laminates

TP material PCB is a unique high-frequency thermoplastic material in the industry. The dielectric layer of TP-type laminates PCB consists of ceramics and polyphenylene Oxide resin (PPO), without fiberglass reinforcement. The dielectric constant can be precisely adjusted by adjusting the ratio between ceramics and PPO resin. The production process is special, and it has excellent dielectric performance and high reliability.TP PCB refers to the smooth surface material without copper cladding,TP-1 PCB refers to the material with copper cladding on one side, and TP-2 PCB refers to the material with copper cladding on both sides.

Data Sheet (TP Laminates)

|

Product Technical Parameter

|

Product Models & Data Sheet

|

|

Product Features

|

Test Conditions

|

Unit

|

TP TP-1 TP-2

|

|

Dielectric Constant

|

When the dielectric constant is ≤11, the test condition is 10GHz.

When the dielectric constant is >11, the test condition is 5GHz.

|

/

|

3.0±0.06

|

4.4±0.09

|

6.0±0.12

|

|

6.15±0.12

|

9.2±0.18

|

9.6±0.19

|

|

10.2±0.2

|

11.0±0.022

|

16.0±0.4

|

|

20.0±0.8

|

22.0±0.88

|

25.0±1.0

|

|

The dielectric constant can be customized within the range of 3.0 to 25.

|

|

Dielectric Constant Tolerance

|

Dielectric Constant 3.0~11.0

|

/

|

±2%

|

|

Dielectric Constant 11.1~16.0

|

/

|

±2.5%

|

|

Dielectric Constant 16.1~25.0

|

/

|

±4%

|

|

Loss Tangent

|

Loss Tangent 3.0~9.5

|

10GHz

|

/

|

0.0010

|

|

Loss Tangent 9.6~11.0

|

10GHz

|

/

|

0.0012

|

|

Loss Tangent 11.1~16.0

|

5GHz

|

/

|

0.0015

|

|

Loss Tangent 16.1~25.0

|

5GHz

|

/

|

0.0020~0.0025

|

|

Dielectric Constant Temperature Coefficient

|

Dielectric Constant 3.0~9.5

|

-55 º~150ºC

|

PPM/℃

|

-50

|

|

Dielectric Constant 9.6~16.0

|

-55 º~150ºC

|

PPM/℃

|

-40

|

|

Dielectric Constant 16.1~25.0

|

-55 º~150ºC

|

PPM/℃

|

-55

|

|

Peel Strength

|

1 OZ Normal State

|

N/mm

|

>0.6

|

|

1 OZ After AC Humidity Test

|

N/mm

|

>0.4

|

|

Volume Resistivity

|

Normal State at 500V

|

MΩ.cm

|

>1×109

|

|

Surface Resistivity

|

Normal State at 500V

|

MΩ

|

>1×107

|

Coefficient of Thermal Expansion

(XY Z)

|

Dielectric Constant 3.00~4.40

|

-55 º~150ºC

|

PPM/℃

|

60,60,70

|

|

Dielectric Constant 4.60~6.15

|

-55 º~150ºC

|

PPM/℃

|

50,50,60

|

|

Dielectric Constant 6.16~11.0

|

-55 º~150ºC

|

PPM/℃

|

40,40,55

|

|

Dielectric Constant 11.1~16.0

|

-55 º~150ºC

|

PPM/℃

|

40,40,50

|

|

Dielectric Constant 16.1~25.0

|

-55 º~150ºC

|

PPM/℃

|

35,35,40

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.01

|

|

Long-Term Operating Temperature

|

High-Low Temperature Chamber

|

℃

|

-100º~150ºC

|

|

Material Composition

|

Polyphenylene ether, ceramic, paired with ED copper foil.

|

|

The density and thermal conductivity data for materials with different dielectric constants are as follows:

|

|

Product Features

|

Unit

|

Dielectric Constanct

|

|

3.0

|

4.4

|

6.0

|

6.15

|

9.6

|

10.2

|

11.0

|

16.0

|

20.0

|

22.0

|

25.0

|

|

Density

|

g/cm3

|

1.69

|

1.89

|

2.1

|

2.12

|

2.26

|

2.33

|

2.40

|

2.76

|

2.73

|

2.77

|

2.94

|

|

Thermal Conductivity

|

W/(M.K)

|

0.40

|

0.44

|

0.55

|

0.55

|

0.65

|

0.67

|

0.70

|

0.80

|

0.85

|

0.90

|

1.0

|

Other Available High Frequency Materials

Rogers RO4350B, RO4003C, RO4730G3, RO4360G2,RO4533, RO4534, RO4535,RO3003, RO3035, RO3006, RO3010, RO3210, RO3203, etc.

Rogers RT/duroid 5880, RT/duroid 5870, RT/duroid 6002, RT/duroid 6010, RT/duroid 6035HTC etc.

Rogers TMM4, TMM10, Kappa 438 etc.

PTFE F4B DK2.2, DK2.65

Taconic TLX-0, TLX-9, TLX-8, TLX-7, TLX-6, TLY-5, TLY-3, RF-35TC, RF-35,TLF-35, RF-60A, RF-60TC, RF-35, RF-35A2, RF-45, TRF-45, RF-10 etc.

AD450, AD600, AD1000, TC350 etc.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com