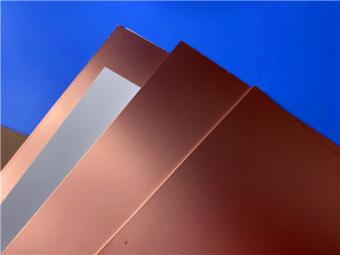

F4BM217 PTFE Glass ClothF4B DK2.17Copper Clad Laminate

Product Overview

Wangling F4BM217 is a high-performance PTFE glass cloth copper clad laminate belonging to the F4BM series, developed by Taizhou Wangling Insulation Materials Factory. It is crafted through scientific formulation and rigorous manufacturing processes, combining glass fiber cloth, polytetrafluoroethylene (PTFE) resin, and PTFE film as core raw materials.

Compared with conventional F4B materials, F4BM217 laminate boasts enhanced electrical performance, featuring a stable dielectric constant, low dielectric loss, and increased insulation resistance. It can serve as a reliable alternative to similar foreign products. Specifically designed for applications without PIM requirement, this laminate is paired with ED copper foil, which ensures excellent process compatibility and meets the performance needs of various high-frequency and high-reliability electronic devices.

A key advantage of F4BM217 DK2.17 substrate lies in its precisely adjustable dielectric properties. By optimizing the ratio of PTFE to glass fiber cloth, it achieves both low loss and outstanding dimensional stability. With a fixed dielectric constant of 2.17, it strikes a perfect balance between signal transmission efficiency and structural stability.

Core Features

1) Fixed dielectric constant (DK) of 2.17, with a tight tolerance of±0.04, ensuring consistent electrical performance.

2) Ultra-low dielectric loss: 0.001 at 10GHz and 0.0014 at 20GHz, enabling efficient high-frequency signal transmission.

3) Equipped with ED copper foil, ideal for applications that do not require PIM indicators.

4) Diverse size and thickness options, supporting cost optimization through customized specifications.

5) Excellent resistance to radiation and low outgassing, suitable for harsh operating environments.

6) Commercialized mass production, offering high cost-effectiveness without compromising quality.

Technical Specifications of F4BM217

|

Product Characteristics

|

Test Conditions

|

Unit

|

F4BM217 Value

|

|

Dielectric Constant (Typical Value)

|

10GHz (Z-direction)

|

-

|

2.17

|

|

Dielectric Constant Tolerance

|

-

|

-

|

±0.04

|

|

Dissipation Factor (Typical Value)

|

10GHz

|

-

|

0.001

|

|

Dissipation Factor (Typical Value)

|

20GHz

|

-

|

0.0014

|

|

Temperature Coefficient of Dielectric Constant

|

-55℃~150℃

|

PPM/℃

|

-150

|

|

Peel Strength (1 OZ)

|

-

|

N/mm

|

>1.8

|

|

Volume Resistivity

|

Normal State

|

MΩ.cm

|

≥6×10⁶

|

|

Surface Resistivity

|

Normal State

|

MΩ

|

≥1×10⁶

|

|

Electrical Strength (Z-direction)

|

5KW, 500V/s

|

KV/mm

|

>23

|

|

Breakdown Voltage (XY-direction)

|

5KW, 500V/s

|

KV

|

>30

|

|

Coefficient of Thermal Expansion (CTE)

|

XY-direction, -55℃~288℃

|

ppm/℃

|

25-34

|

|

Coefficient of Thermal Expansion (CTE)

|

Z-direction, -55℃~288℃

|

ppm/℃

|

240

|

|

Thermal Stress

|

260℃, 10s, 3 cycles

|

-

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm³

|

2.17

|

|

Continuous Operating Temperature

|

-

|

℃

|

-55~+260

|

|

Thermal Conductivity

|

Z-direction

|

W/(M.K)

|

0.24

|

|

Flame Retardancy

|

-

|

UL-94

|

V-0

|

|

Material Composition

|

-

|

-

|

PTFE, glass fiber cloth, ED copper foil

|

Optional Copper Foil (ED Copper Foil for F4BM217)

|

Copper Foil Thickness

|

Specification (mm)

|

|

0.5OZ

|

0.018

|

|

1OZ

|

0.035

|

|

1.5OZ

|

0.05

|

|

2OZ

|

0.07

|

Standard Sizes

460×610mm

500×600mm

850×1200mm

914×1220mm

1000×1200mm

Custom Sizes (Contact us for special requirements)

300×250mm

350×380mm

500×500mm

840×840mm

1000×1500mm

Note: For thickness≥4.0mm or≤0.2mm, the maximum size is limited to 500×610mm.

Thickness & Tolerance

F4BM217 copper clad laminate has a dielectric constant of 2.17 (≤2.65), so the minimum available dielectric thickness is 0.1mm. Below are the conventional thickness options (specify "total thickness including copper" or "dielectric thickness" when ordering):

|

Dielectric Thickness (mm)

|

Tolerance (mm)

|

|

0.1

|

±0.01

|

|

0.127

|

±0.01

|

|

0.2

|

±0.02

|

|

0.25

|

±0.02

|

|

0.5

|

±0.04

|

|

0.508

|

±0.04

|

|

0.762

|

±0.05

|

|

0.8

|

±0.05

|

|

1

|

±0.05

|

|

1.5

|

±0.06

|

|

1.524

|

±0.06

|

|

1.575

|

±0.06

|

|

2

|

±0.08

|

|

2.5

|

±0.08

|

|

3

|

±0.09

|

|

4

|

±0.1

|

|

5

|

±0.1

|

|

6

|

±0.12

|

|

8

|

±0.15

|

|

10

|

±0.18

|

|

12

|

±0.2

|

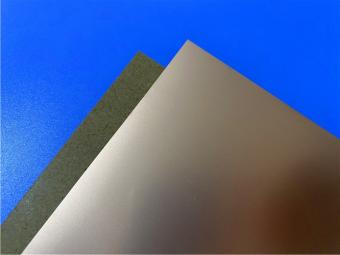

Metal-Based Variant (Optional)

F4BM217 is also available in aluminum-based or copper-based versions, designed for shielding or heat dissipation purposes. The metal layer is applied to one side of the dielectric layer (the other side is copper foil), with the following specifications:

|

Model

|

Metal Base

|

Specific Gravity

|

Thermal Conductivity (W/(M.K))

|

Available Metal Base Thickness (mm)

|

Metal Base Tolerance (mm)

|

Available Sizes (mm)

|

|

F4BM217-CU

|

Red Copper/Brass

|

8.9

|

380

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (customizable)

|

+0.02, -0.05

|

460×610, 460×305 (customizable)

|

|

F4BM217-AL

|

Aluminum

|

2.7

|

180

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (customizable)

|

+0.02, -0.05

|

460×610, 460×305 (customizable)

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com