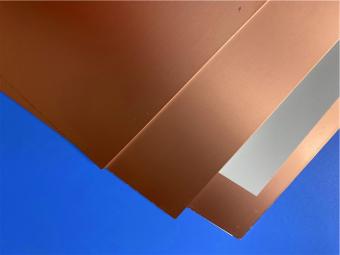

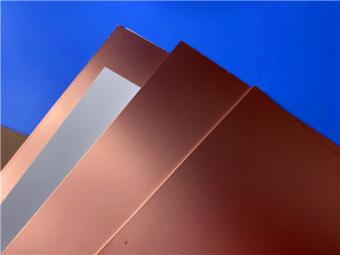

Rogers DiClad 527 DK2.4-2.6 DiClad Series Copper Clad Laminate

Product Overview

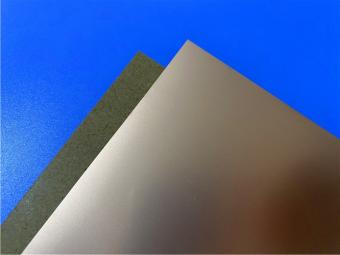

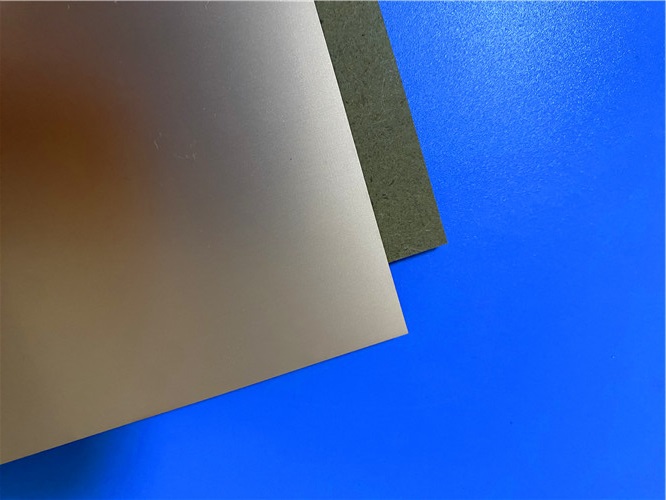

DiClad 527 is a high-performance laminate belonging to Rogers DiClad Series, which is composed of a woven fiberglass and PTFE (polytetrafluoroethylene) composite. Specifically engineered for use as a printed circuit board (PCB) substrate, this material stands out due to its precisely controlled fiberglass-to-PTFE ratio. This careful formulation not only delivers a well-balanced set of properties but also ensures exceptional dimensional stability, a key advantage over non-woven fiberglass-reinforced PTFE laminates with similar dielectric constants.

The woven fiberglass reinforcement in DiClad 527 laminate contributes to its robust mechanical performance, including superior dimensional stability and lower thermal expansion across all directions—characteristics that closely approach those of conventional PCB substrates. Additionally, the consistent quality of its PTFE-coated fiberglass cloth ensures excellent uniformity in dielectric constant, making it a reliable choice for applications where signal integrity and performance consistency are critical.

DiClad 527 substrates are particularly well-suited for scenarios demanding precise dielectric constant uniformity and low signal loss. Typical applications include filters, couplers, low-noise amplifiers (LNAs), power dividers, and combiners. They are also widely used in high-performance systems such as military radar feed networks, commercial phased array networks, low-loss base station antennas, missile guidance systems, and digital radio antennas.

The electrical properties of Rogers DiClad 527 are rigorously tested at two key frequencies: 1 MHz and 10 GHz, ensuring its performance is verified across a broad spectrum of operational conditions.

Key Features & Benefits

1)Extremely low loss tangent, minimizing signal attenuation in high-frequency applications.

2)Excellent dimensional stability, supported by woven fiberglass reinforcement for reliable performance in varying environments.

3)Consistent product performance, with uniform electrical and mechanical properties across the material.

4)Highly uniform electrical characteristics across a wide frequency range, simplifying design processes for multi-frequency systems.

5)Reliable mechanical performance, including balanced tensile strength, modulus, and copper peel strength.

6)Strong chemical resistance, enhancing durability in harsh operating conditions.

7)Low thermal expansion in all directions, reducing the risk of warping or damage during temperature fluctuations.

Technical Specifications Table

|

Property Category

|

Specific Property

|

Typical Value

|

Unit

|

Test Conditions

|

Test Method

|

|

Electrical Properties

|

Dielectric Constant

|

2.40 - 2.60

|

-

|

23˚C @ 50% RH, 10 GHz

|

IPC TM-650 2.5.5.5

|

|

Electrical Properties

|

Dielectric Constant

|

2.40 - 2.60

|

-

|

23˚C @ 50% RH, 1 MHz

|

IPC TM-650 2.5.5.3

|

|

Electrical Properties

|

Dissipation Factor

|

0.0017

|

-

|

23˚C @ 50% RH, 10 GHz

|

IPC TM-650 2.5.5.5

|

|

Electrical Properties

|

Dissipation Factor

|

0.001

|

-

|

23˚C @ 50% RH, 1 MHz

|

IPC TM-650 2.5.5.3

|

|

Electrical Properties

|

Thermal Coefficient of Dielectric Constant

|

-153

|

ppm/˚C

|

-10 to 140˚C, 10 GHz

|

IPC TM-650 2.5.5.5

|

|

Electrical Properties

|

Volume Resistivity

|

1.2 x 10⁹

|

MΩ-cm

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Electrical Properties

|

Surface Resistivity

|

4.5 x 10⁷

|

MΩ

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Electrical Properties

|

Dielectric Breakdown

|

>45

|

kV

|

D48/50

|

ASTM D-149

|

|

Electrical Properties

|

Arc Resistance

|

>180

|

-

|

-

|

ASTM D-495

|

|

Thermal Properties

|

Coefficient of Thermal Expansion (x-axis)

|

14

|

ppm/˚C

|

50˚C to 150˚C

|

IPC TM-650 2.4.41

|

|

Thermal Properties

|

Coefficient of Thermal Expansion (y-axis)

|

21

|

ppm/˚C

|

50˚C to 150˚C

|

IPC TM-650 2.4.41

|

|

Thermal Properties

|

Coefficient of Thermal Expansion (z-axis)

|

173

|

ppm/˚C

|

50˚C to 150˚C

|

IPC TM-650 2.4.24

|

|

Thermal Properties

|

Thermal Conductivity

|

0.26

|

W/(m.K)

|

-

|

ASTM E1461

|

|

Mechanical Properties

|

Copper Peel Strength

|

14

|

Lbs/in

|

10s @ 288˚C, 35 μm foil

|

IPC TM-650 2.4.8

|

|

Mechanical Properties

|

Young’s Modulus

|

517, 706

|

kpsi

|

23˚C @ 50% RH

|

ASTM D-638

|

|

Mechanical Properties

|

Tensile Strength (MD, CMD)

|

19.0, 15.0

|

kpsi

|

23˚C @ 50% RH

|

ASTM D-882

|

|

Mechanical Properties

|

Compressive Modulus

|

359

|

kpsi

|

23˚C @ 50% RH

|

ASTM D-695

|

|

Mechanical Properties

|

Flex Modulus

|

537

|

kpsi

|

23˚C @ 50% RH

|

ASTM D-3039

|

|

Physical Properties

|

Flammability Rating

|

V-0

|

-

|

C48/23/50 & C168/70

|

UL 94

|

|

Physical Properties

|

Moisture Absorption

|

0.03

|

%

|

E1/105 + D24/23

|

IPC TM-650 2.6.2.2

|

|

Physical Properties

|

Density

|

2.31

|

g/cm³

|

C24/23/50, Method A

|

ASTM D792

|

|

NASA Outgassing

|

Total Mass Lost

|

0.02

|

%

|

125°C, ≤ 10⁻⁶ torr

|

NASA SP-R-0022A

|

|

NASA Outgassing

|

Collected Volatiles

|

0

|

%

|

125°C, ≤ 10⁻⁶ torr

|

NASA SP-R-0022A

|

|

NASA Outgassing

|

Water Vapor Recovered

|

0.01

|

%

|

125°C, ≤ 10⁻⁶ torr

|

NASA SP-R-0022A

|

Standard Offerings

|

Specification Type

|

Details

|

|

Standard Thicknesses

|

- 0.020” (0.508mm) ± 0.0020”

|

|

- 0.030” (0.762mm) ± 0.0020”

|

|

- 0.060” (1.524mm) ± 0.0020”

|

|

Standard Panel Sizes

|

- 12” x 18” (305mm x 457mm)

|

|

- 18” x 12” (457mm x 305mm)

|

|

- 18” x 24” (457mm x 610mm)

|

|

- 24” x 18” (610mm x 457mm)

|

|

Standard Claddings

|

Electrodeposited Copper Foil: 1/2 oz. (18µm), 1 oz. (35µm)

|

Disclaimer: The information provided herein is derived from Rogers Corporation's original data sheet and is intended to assist in PCB design and material selection. It does not create any express or implied warranties, including warranties of merchantability or fitness for a particular purpose. Users should verify the suitability of DiClad 527 for their specific applications.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com