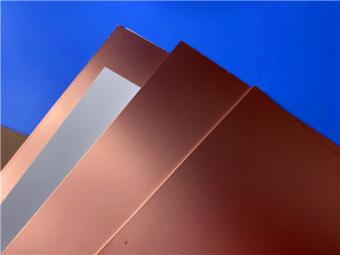

Rogers CuClad 217 PCB Copper Clad Laminates DK2.17 Double-Sided Raw Material

Product Overview

Rogers CuClad 217 is a high-performance printed circuit board (PCB) substrate belonging to Rogers Corporation CuClad series, crafted from a composite of woven fiberglass and PTFE (polytetrafluoroethylene). It is engineered with a low fiberglass-to-PTFE ratio, enabling it to deliver the lowest dielectric constant and dissipation factor among fiberglass-reinforced PTFE-based laminates. These exceptional electrical properties translate to faster signal propagation and superior signal-to-noise ratios, making it a top choice for applications where signal integrity is non-negotiable.

A key structural advantage of CuClad 217 substrate is its crossplied design—alternating layers of PTFE-coated fiberglass plies are oriented at 90°to one another. This unique construction ensures true electrical and mechanical isotropy in the X-Y plane, a distinguishing feature exclusive toCuClad laminates. Designers have recognized this level of isotropy as critical for specialized applications such as phased array antennas.

For mission-critical applications requiring rigorous performance validation, CuClad 217 laminates can be specified with the“LX”testing grade. Products marked with“LX”undergo individual testing for each sheet, and a comprehensive test report is provided with the order. It is important to note that“LX”grade products come at a higher cost, as a portion of each sheet is used for destructive testing to verify performance consistency.

Core Features

1) Crossplied woven fiberglass structure, with alternating plies oriented at 90°to one another

2) High PTFE-to-glass ratio, optimizing electrical performance

3) Superior dielectric constant uniformity compared to comparable non-woven fiberglass-reinforced PTFE laminates

Key Benefits

1) Electrical and mechanical isotropy in the X-Y plane, ensuring consistent performance across the substrate

2) Extremely low signal loss, preserving signal integrity even in high-frequency applications

3) Well-suited for circuits sensitive to dielectric constant (Er) variations, supporting reliable design outcomes

Typical Applications

Military electronics: Radars, Electronic Countermeasures (ECM), Electronic Support Measures (ESM)

Microwave components: Low Noise Amplifiers (LNAs), filters, couplers, and other high-frequency devices

Typical Performance Parameters

|

Property

|

Test Method

|

Condition

|

CuClad 217 Value

|

|

Dielectric Constant @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

2.17, 2.20

|

|

Dielectric Constant @ 1 MHz

|

IPC TM-650 2.5.5.3

|

C23/50

|

2.17, 2.20

|

|

Dissipation Factor @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

0.0009

|

|

Thermal Coefficient of Er (ppm/°C)

|

IPC TM-650 2.5.5.5 Adapted

|

-10°C to +140°C

|

-160

|

|

Peel Strength (lbs. per inch)

|

IPC TM-650 2.4.8

|

After Thermal Stress

|

14

|

|

Volume Resistivity (MΩ-cm)

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

2.3 x 10⁸

|

|

Surface Resistivity (MΩ)

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

3.4 x 10⁶

|

|

Arc Resistance (seconds)

|

ASTM D-495

|

D48/50

|

> 180

|

|

Tensile Modulus (kpsi)

|

ASTM D-638

|

A, 23°C

|

275, 219

|

|

Tensile Strength (kpsi)

|

ASTM D-882

|

A, 23°C

|

8.8, 6.6

|

|

Compressive Modulus (kpsi)

|

ASTM D-695

|

A, 23°C

|

237

|

|

Flexural Modulus (kpsi)

|

ASTM D-790

|

A, 23°C

|

357

|

|

Dielectric Breakdown (kV)

|

ASTM D-149

|

D48/50

|

> 45

|

|

Specific Gravity (g/cm³)

|

ASTM D-792 Method A

|

A, 23°C

|

2.23

|

|

Water Absorption (%)

|

MIL-S-13949H 3.7.7 / IPC TM-650 2.6.2.2

|

E1/105 + D24/23

|

0.02

|

|

Coefficient of Thermal Expansion (ppm/°C) X Axis, Y Axis, Z Axis

|

IPC TM-650 2.4.24 / Mettler 3000 Thermomechanical Analyzer

|

0°C to 100°C

|

29, 28, 246

|

|

Thermal Conductivity

|

ASTM E-1225

|

100°C

|

0.26

|

|

Outgassing

Total Mass Loss (%)

Collected Volatile

Condensable Material (%) Water Vapor Regain (%) Visible Condensate (±)

|

NASA SP-R-0022A

Maximum 1.00%

Maximum 0.10%

|

125°C, ≤ 10-6 torr

|

0.01

0.01

0.00

NO

|

|

Flammability

|

UL 94 Vertical Burn IPC TM-650 2.3.10

|

C48/23/50, E24/125

|

Meets requirements of UL94-V0

|

4. Standard Specifications

|

Category

|

Details

|

Tolerance

|

|

Standard Thicknesses

|

0.010" (0.25mm)

|

±0.0010"

|

|

0.020" (0.51mm)

|

±0.0020"

|

|

0.031" (0.79mm)

|

±0.0020"

|

|

0.062" (1.57mm)

|

±0.0020"

|

|

Standard Panel Sizes

|

18" × 12" (457×305mm)

|

-

|

|

18" × 24" (457×610mm)

|

|

Standard Cladding

|

Electrodeposited Copper Foil

|

-

|

|

- ½ oz. (18μm) HH/HH

|

|

- 1 oz. (35μm) H1/H1

|

Additional Options:

Non-standard thicknesses: Available from 0.005" to 0.250" in custom increments.

Custom panel sizes: Contact customer service for tailored dimensions.

Special claddings: Heavy metal ground planes, resistive foil, or unclad configurations (inquire with sales engineering).

Disclaimer: This data is derived from typical properties of CuClad 217 and is not intended as specification limits. Rogers Corporation does not warrant merchantability or fitness for specific applications. Users must verify suitability for their intended use.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com