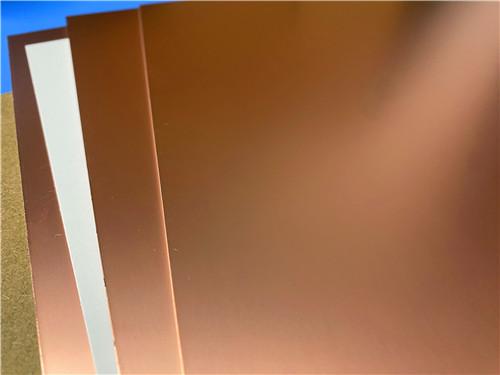

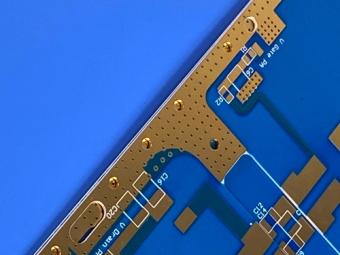

Wangling F4BTMS220 DK2.2 F4B 0.09mm-6.35mm Copper Clad Laminates

The F4BTMS220 substrate is a core model within the F4BTMS series, which represents an upgraded iteration of the F4BTM series with pivotal technological breakthroughs in material formulation and manufacturing processes. This laminate is reinforced with ultra-thin and ultra-fine (quartz) glass fiber cloth, and its material system incorporates a homogeneous mixture of a large quantity of special nano-ceramics and polytetrafluoroethylene (PTFE) resin. This unique composition effectively minimizes the glass fiber effect and dielectric loss during electromagnetic wave propagation, while significantly enhancing dimensional stability, reducing anisotropy in the X/Y/Z directions, and optimizing operating frequency, electrical strength, and thermal conductivity. It also boasts excellent low coefficient of thermal expansion and stable dielectric temperature characteristics.

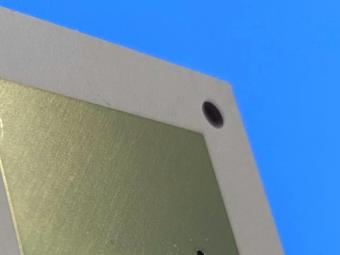

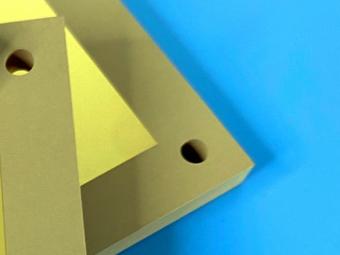

Standard-equipped with RTF low-roughness copper foil, the F4BTMS220 laminate reduces conductor loss while ensuring outstanding peel strength, and can be flexibly paired with copper or aluminum substrates. Circuit board processing can adopt standard PTFE laminate process technology; its superior mechanical and physical properties make it suitable for the fabrication of multi-layer,high-multi-layer PCBs and backplanes, and it also demonstrates excellent processability in scenarios involving dense holes and fine circuits. As an aerospace-grade high-reliability material, the F4BTMS220 Wangling laminate is capable of substituting for comparable foreign-manufactured products, and is widely applied in high-end fields such as aerospace equipment, space and in-cabin devices, microwave/RF equipment, radars (including military radars), feed networks, phase-sensitive antennas, phased array antennas, and satellite communications.

Product Features

-

Narrow dielectric constant tolerance with superior batch-to-batch consistency;

-

Features ultra-low dielectric loss;

-

Maintains stable dielectric constant and loss value within the operating frequency of up to 40GHz, meeting the requirements of phase-sensitive applications;

-

Excellent temperature coefficient of dielectric constant and dielectric loss, retaining reliable frequency and phase stability within the range of -55℃to 150℃;

-

Outstanding radiation resistance, maintaining stable dielectric and physical properties even after radiation exposure;

-

Low outgassing performance, complying with aerospace vacuum outgassing requirements when tested in accordance with standard methods for material volatility under vacuum conditions;

-

Small coefficient of thermal expansion in X/Y/Z directions, ensuring dimensional thermal stability and hole copper reliability;

-

Superior thermal conductivity, suitable for high-power application scenarios;

-

Excellent dimensional stability;

-

Low water absorption.

Technical Specifications Table

|

Product Characteristic

|

Test Condition

|

Unit

|

F4BTMS220

|

|

Dielectric Constant (Typ.)

|

10GHz

|

–

|

2.2

|

|

Dielectric Constant Tolerance

|

–

|

–

|

±0.02

|

|

Dielectric Constant (Design)

|

10GHz

|

–

|

2.2

|

|

Loss Tangent (Typ.)

|

10GHz

|

–

|

0.0009

|

|

20GHz

|

–

|

0.001

|

|

40GHz

|

–

|

0.0013

|

|

TCDK

|

–55℃~150℃

|

ppm/℃

|

–130

|

|

Peel Strength

|

1 oz RTF Cu

|

N/mm

|

>2.4

|

|

Volume Resistivity

|

Normal

|

MΩ·cm

|

≥1×10⁸

|

|

Surface Resistance

|

Normal

|

MΩ

|

≥1×10⁸

|

|

Electric Strength (Z)

|

5kV, 500V/s

|

kV/mm

|

>26

|

|

Breakdown Voltage (XY)

|

5kV, 500V/s

|

kV

|

>35

|

|

CTE (X, Y)

|

–55℃~288℃

|

ppm/℃

|

40–50

|

|

CTE (Z)

|

–55℃~288℃

|

ppm/℃

|

290

|

|

Thermal Stress

|

260℃, 10s, 3 cycles

|

–

|

No delamination

|

|

Water Absorption

|

20±2℃, 24h

|

%

|

0.02

|

|

Density

|

Room temp.

|

g/cm³

|

2.18

|

|

Long-term Use Temp.

|

–

|

℃

|

–55~+260

|

|

Thermal Conductivity

|

Z-direction

|

W/(m·K)

|

0.26

|

|

Flammability Rating

|

–

|

UL-94

|

V-0

|

|

Material Composition

|

–

|

–

|

PTFE, ultra-thin ultra-fine (quartz) glass fiber

|

Test Method Notes

The dielectric constant (typical value) is tested in the Z direction of the material, using the strip line method specified in GB/T 12636-1990 or IPC-TM650 2.5.5.5;

Other performance tests are conducted in accordance with or with reference to the test methods specified in IPC-TM-650 or GBT4722-2017;

All test data are typical measurement values, intended to assist customers in material selection. They do not constitute any express or implied warranties, nor do they guarantee that customers will achieve all the performance indicated in this data sheet in specific applications. Customers are responsible for verifying the suitability ofWangling materials in each application.

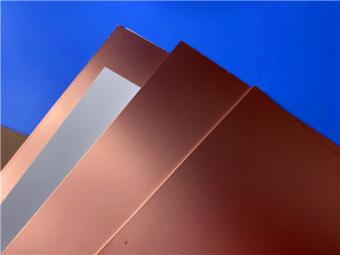

Optional Copper Foil

-

Copper Foil Thickness: 0.5OZ (0.018mm), 1OZ (0.035mm); other thicknesses can be customized upon request;

-

Copper Foil Type: Standard RTF low-roughness copper foil;

-

Optional Types: 50Ωembedded resistor copper foil, aluminum substrate, copper substrate;

50Ω Embedded Resistor Copper Foil Description: The resistor film is made of nickel-phosphorus alloy, with a thickness of 0.2 microns and a sheet resistance of 50±5Ωper square centimeter.

AvailableSize

305×460 mm, 460×610 mm, 610×920 mm (custom sizes available)

Dielectric Layer Thickness and Tolerance

Minimum Thickness: 0.09mm;

Available Thicknesses: Products with multiples of 0.09mm or 0.127mm are provided.

|

Thickness (mm)

|

Tolerance (mm)

|

|

0.09

|

±0.010

|

|

0.127

|

±0.0127

|

|

0.254

|

±0.02

|

|

0.508

|

±0.03

|

|

0.635

|

±0.04

|

|

0.762

|

±0.04

|

|

0.787

|

±0.04

|

|

1.016

|

±0.05

|

|

1.27

|

±0.05

|

|

1.5

|

±0.06

|

|

1.524

|

±0.06

|

|

1.575

|

±0.06

|

|

2.03

|

±0.08

|

|

2.54

|

±0.10

|

|

3.175

|

±0.13

|

|

4.06

|

±0.18

|

|

5.08

|

±0.20

|

|

6.35

|

±0.25

|

Special thicknesses are available through customization; please contact our company for details.

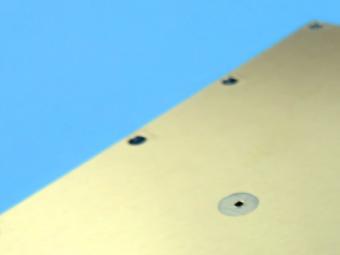

Aluminum/Copper Base Substrates (F4BTMS220-AL / F4BTMS220-CU)

The series can be supplied with aluminum or copper backing for shielding or heat dissipation.

|

Model

|

Metal Base

|

Specific Gravity

|

Thermal Conductivity (W/m·K)

|

CTE (ppm/℃)

|

Available Metal Thickness (mm)

|

Thickness Tolerance (mm)

|

Available Size (mm)

|

|

F4BTMS220-CU

|

Copper

|

8.9

|

380

|

17

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (custom available)

|

+0.02, –0.05

|

460×610, 460×305

|

|

F4BTMS220-AL

|

Aluminum

|

2.7

|

180

|

24

|

Same as above

|

Same as above

|

Same as above

|

Electrical Performance Explanation

Frequency variations are based on the median dielectric constant and median loss at 10GHz, while temperature variations are referenced to the median dielectric constant and median loss at room temperature (23℃). These are approximate values of variation trends derived from cumulative data statistics. This explanation aims to illustrate the variation trend of the F4BTMS220 material and does not represent the specific data of each individual product; however, the variation trend of all products is consistent with the following rules:

Excellent frequency stability: Within the frequency range of 0.5~40GHz, the material maintains stable dielectric constant and loss, retaining ultra-low loss values to meet design requirements under different frequencies;

Within the temperature range of -55~150℃, the temperature coefficient of dielectric constant (TCDK) is approximately -130PPM/℃, providing reference data for designs in various temperature environments. The actual usable temperature of the material is far beyond this range.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com