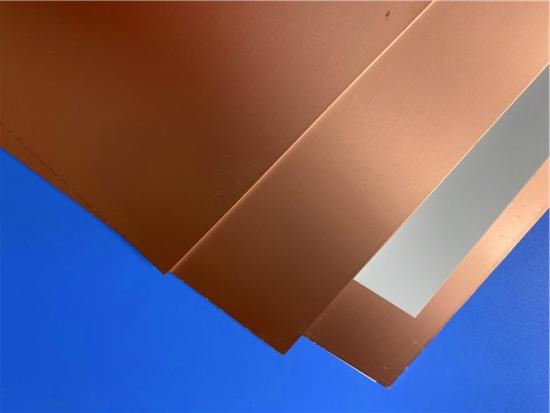

Rogers DiClad 870 DiClad Series DK2.33 PTFE Woven Fiberglass Laminates

DiClad 870 is a high-performance laminate belonging to Rogers Corporation’s DiClad substrate Series, which is composed of a woven fiberglass and PTFE (polytetrafluoroethylene) composite. Designed specifically for use as a printed circuit board (PCB) substrate, this DiClad 870 material is engineered with precise control over the fiberglass-to-PTFE ratio, delivering a balanced combination of electrical, thermal, mechanical, and physical properties tailored for demanding high-frequency applications.

Core Characteristics & Advantages

1)Exceptional Electrical Performance: Boasts a low and stable dielectric constant, paired with an ultra-low dissipation factor. These properties remain highly uniform across a broad frequency range, ensuring reliable signal integrity—critical for high-frequency applications where signal loss and consistency are paramount.

2)Superior Dimensional Stability: The woven fiberglass reinforcement within the laminate provides enhanced dimensional stability compared to non-woven fiberglass-reinforced PTFE-based laminates with similar dielectric constants. This stability minimizes dimensional variations under different environmental conditions, supporting precise PCB manufacturing and performance.

3)Consistent Overall Performance: Offers uniform product performance, including reliable mechanical properties and consistent electrical behavior. This consistency simplifies design processes and ensures scalability across different project requirements.

4)Strong Chemical Resistance: Exhibits excellent resistance to various chemicals, enhancing its durability and suitability for use in harsh operating environments.

Key Application Areas

Rogers DiClad 870 laminates are ideally suited for applications that demand low signal loss, stable dielectric properties, and reliable mechanical performance, such as:

-

Military radar feed networks

-

Commercial phased array networks

-

Low-loss base station antennas

-

Missile guidance systems

-

Digital radio antennas

-

Filters, couplers, and low-noise amplifiers (LNAs)

-

Power dividers and combiners (where low loss is a critical requirement)

DiClad 870 Technical Specifications

|

Property

|

DiClad 870

|

Condition

|

Test Method

|

|

Electrical Properties

|

|

Dielectric Constant @ 10 GHz

|

2.33

|

C23/50

|

IPC TM-650 2.5.5.5

|

|

Dielectric Constant @ 1 MHz

|

2.33

|

C23/50

|

IPC TM-650 2.5.5.3

|

|

Dissipation Factor @ 10 GHz

|

0.0013

|

C23/50

|

IPC TM-650 2.5.5.5

|

|

Dissipation Factor @ 1 MHz

|

0.0009

|

C23/50

|

IPC TM-650 2.5.5.3

|

|

Thermal Coefficient of Er (ppm/°C)

|

-161

|

-10°C to +140°C

|

IPC TM-650 2.5.5.5

Adapted

|

|

Volume Resistivity (MΩ-cm)

|

1.5 x 109

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity (MΩ)

|

3.4 x 107

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Arc Resistance

|

>180

|

D48/50

|

ASTM D-495

|

|

Dielectric Breakdown (kV)

|

>45

|

D48/50

|

ASTM D-149

|

|

Mechanical Properties

|

|

Peel Strength (lbs.per inch)

|

14

|

After Thermal Stress

|

IPC TM-650 2.4.8

|

|

Tensile Modulus (kpsi)

|

485(MD), 346(CD)

|

A, 23°C

|

ASTM D-638

|

|

Tensile Strength (kpsi)

|

14.9(MD), 11.2 (CD)

|

A, 23°C

|

ASTM D-882

|

|

Compressive Modulus (kpsi)

|

327

|

A, 23°C

|

ASTM D-695

|

|

Flexural Modulus (kpsi)

|

437

|

A, 23°C

|

ASTM D-790

|

|

Thermal Properties

|

|

Coefficient of Thermal Expansion (ppm/°C) X Axis Y Axis Z Axis

|

17 29 217

|

0°C to 100°C

|

IPC TM-650 2.4.24 Mettler 3000 Thermomechanical Analyzer

|

|

Thermal Conductivity (W/mK)

|

0.257

|

100°C

|

ASTM E-1225

|

|

Flammability UL

|

Meets requirements of UL94-V0

|

C48/23/50, E24/125

|

UL 94 Vertical Burn IPC TM-650 2.3.10

|

|

Physical Properties

|

|

Density (g/cm3)

|

2.26

|

A, 23°C

|

ASTM D-792 Method A

|

|

Water Absorption (%)

|

0.02

|

E1/105 + D24/23

|

MIL-S-13949H 3.7.7

IPC TM-650 2.6.2.2

|

|

Outgassing Total Mass Loss (%) Collected Volatile Condensable Material (%) Water Vapor Regain (%) Visible Condensate (±)

|

0.02 0.00 0.01 NO

|

125°C, ≤ 10-6torr

|

NASA SP-R-0022A Maximum 1.00% Maximum 0.10%

|

Standard Offerings

Standard Thicknesses

-

0.031”(0.79mm) with a tolerance of +/- 0.0020”

-

0.093”(2.36mm) with a tolerance of +/- 0.0030”

-

0.125”(3.18mm) with a tolerance of +/- 0.0060”

-

0.020”(0.508mm) with a tolerance of +/- 0.0020”

-

0.030”(0.762mm) with a tolerance of +/- 0.0020”

-

0.060”(1.524mm) with a tolerance of +/- 0.0020”

Standard Panel Sizes

-

8”X 12”(203 X 305mm)

-

18”X 24”(475 X 610mm)

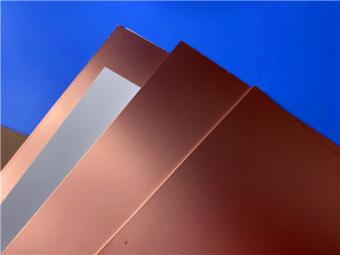

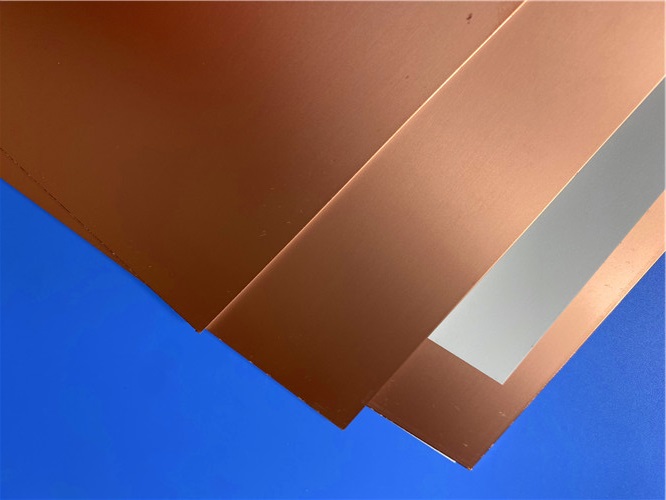

Standard Claddings

|

Cladding Type

|

Thickness Options

|

|

Electrodeposited Copper Foil

|

1/2 oz. (18µm), 1 oz. (35µm)

|

|

Rolled Copper Foil

|

1/2 oz. (18µm), 1 oz. (35µm)

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com