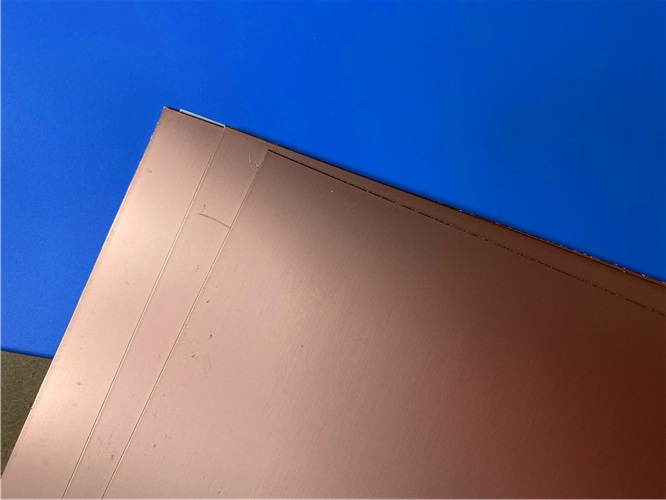

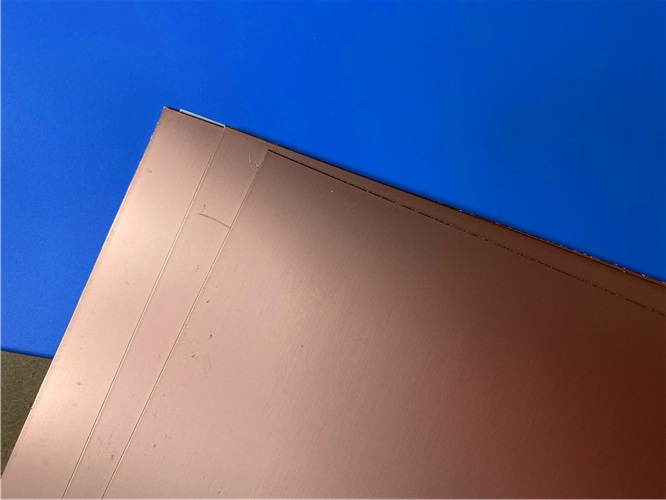

Rogers CuClad 233 CuClad Series DK2.33 WovenFiberglass/PTFEComposite Laminate

Product Overview

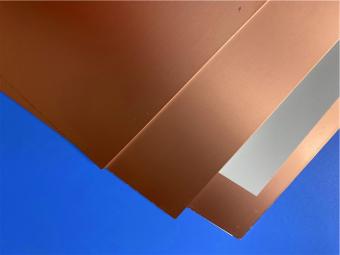

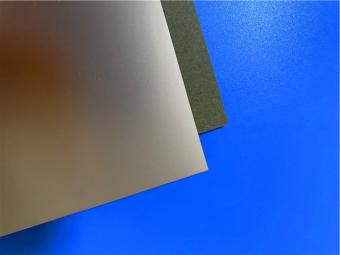

CuClad 233 is a member of Rogers Corporation’s CuClad CCLseries, a line ofwoven fiberglass/PTFE composite laminates designed specifically for printed circuit board (PCB) substrates. ThisRogersmaterial is engineered with a medium fiberglass-to-PTFE ratio, striking an optimal balance between low dielectric constant, improved dissipation factor, and reliable mechanical performance—without compromising on either electrical or structural integrity.

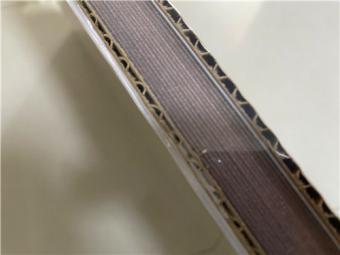

Like all CuClad laminates, CuClad 233 features a crossplied construction, where alternating layers of PTFE-coated fiberglass plies are oriented at 90°to one another. This unique design delivers true electrical and mechanical isotropy in the X-Y plane, a key advantage that sets CuClad products apart from other woven or non-woven fiberglass-reinforced PTFE laminates. This isotropy is particularly critical for applications like phased array antennas, where consistent performance across the circuit board is essential.

The woven fiberglass reinforcement in Rogers CuClad 233 ensures superior dimensional stability compared to non-woven fiberglass-reinforced PTFE laminates with similar dielectric constants. Additionally, the precise control of the PTFE-coated fiberglass cloth guarantees excellent dielectric constant uniformity, makingCuClad 233substrate well-suited for circuits sensitive to dielectric constant (Er) variations.

For critical performance applications, CuClad 233 high frequency laminate can be specified with an“LX”testing grade. Products designated as“LX”undergo individual testing for each sheet, with a detailed test report provided with the order. Note that“LX”grade products are priced higher, as a portion of each sheet is used for destructive testing to verify performance.

Key Features

-

Crossplied woven fiberglass construction (alternating plies oriented at 90°)

-

Medium fiberglass-to-PTFE ratio for balanced electrical and mechanical properties

-

Superior dielectric constant uniformity compared to comparable non-woven fiberglass-reinforced PTFE laminates

-

True electrical and mechanical isotropy in the X-Y plane

-

Extremely low signal loss

-

Ideal for Er-sensitive circuits

Core Benefits

-

Consistent electrical performance across the circuit board due to isotropy

-

Reliable mechanical stability for demanding applications

-

Low dissipation factor supports high signal integrity, especially in high-frequency use cases

-

Balanced dielectric properties enable versatile design integration

-

Typical Applications

-

Military electronics (radars, electronic countermeasures/ECM, electronic support measures/ESM)

-

Microwave components (low noise amplifiers/LNAs, filters, couplers, etc.)

Technical Properties Table

|

Property

|

Test Method

|

Test Condition

|

CuClad 233 Typical Value

|

|

Dielectric Constant @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

2.33

|

|

Dielectric Constant @ 1 MHz

|

IPC TM-650 2.5.5.3

|

C23/50

|

2.33

|

|

Dissipation Factor @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

0.0013

|

|

Thermal Coefficient of Er

|

IPC TM-650 2.5.5.5 (Adapted)

|

-10°C to +140°C

|

-161 ppm/°C

|

|

Peel Strength

|

IPC TM-650 2.4.8

|

After Thermal Stress

|

14 lbs. per inch

|

|

Volume Resistivity

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

8.0 x 10⁸ MΩ-cm

|

|

Surface Resistivity

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

2.4 x 10⁶ MΩ

|

|

Arc Resistance

|

ASTM D-495

|

D48/50

|

> 180 seconds

|

|

Tensile Modulus

|

ASTM D-638

|

A, 23°C

|

510, 414 kpsi

|

|

Tensile Strength

|

ASTM D-882

|

A, 23°C

|

10.3, 9.8 kpsi

|

|

Compressive Modulus

|

ASTM D-695

|

A, 23°C

|

276 kpsi

|

|

Flexural Modulus

|

ASTM D-790

|

A, 23°C

|

371 kpsi

|

|

Dielectric Breakdown

|

ASTM D-149

|

D48/50

|

> 45 kv

|

|

Specific Gravity

|

ASTM D-792 Method A

|

A, 23°C

|

2.26 g/cm³

|

|

Water Absorption

|

MIL-S-13949H 3.7.7 / IPC TM-650 2.6.2.2

|

E1/105 + D24/23

|

0.02%

|

|

Coefficient of Thermal Expansion (CTE)

|

IPC TM-650 2.4.24 (Mettler 3000 Thermomechanical Analyzer)

|

0°C to 100°C

|

X Axis: 23 ppm/°C

|

|

Y Axis: 24 ppm/°C

|

|

Z Axis: 194 ppm/°C

|

|

Thermal Conductivity

|

ASTM E-1225

|

100°C

|

0.26

|

|

Outgassing (Total Mass Loss)

|

NASA SP-R-0022A (Max 1.00%)

|

125°C, ≤ 10⁻⁶ torr

|

0.01%

|

|

Outgassing (Collected Volatile Condensable Material)

|

NASA SP-R-0022A (Max 0.10%)

|

0.01%

|

|

Outgassing (Water Vapor Regain)

|

NASA SP-R-0022A

|

0.00%

|

|

Outgassing (Visible Condensate)

|

NO

|

|

Flammability

|

UL 94 Vertical Burn / IPC TM-650 2.3.10

|

Meets requirements of UL94-V0

|

Standard Specifications

|

Category

|

Details

|

|

Cladding

|

Electrodeposited copper foil (1 oz. / 35 µm, HH/HH; 2 oz. / 70 µm, HH/HH)

|

|

Standard Thicknesses

|

0.010” (0.25 mm) ± 0.0010”

|

|

0.020” (0.51 mm) ± 0.0020”

|

|

0.020” (0.51 mm) ± 0.0020”

|

|

0.062” (1.57 mm) ± 0.0020”

|

|

Standard Panel Sizes

|

18” × 12” (457 × 305 mm)

|

|

18” × 24” (457 × 610 mm)

|

Custom Options

Non-standard thicknesses (available from 0.005” to 0.250” in varying increments)

Custom panel sizes

Alternative claddings (heavy metal ground planes, resistive foil, unclad)

For inquiries about custom configurations, contact customer service or sales engineering.

Disclaimer: The data provided above reflects typical properties of CuClad 233 and is not intended as specification limits. Rogers Corporation makes no express or implied warranties (including merchantability or fitness for a specific purpose) regarding the performance of this material. Users must verify the suitability of CuClad 233 for their specific application. Export of this commodity, technology, or software is subject to U.S. Export Administration Regulations; diversion contrary to U.S. law is prohibited.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com