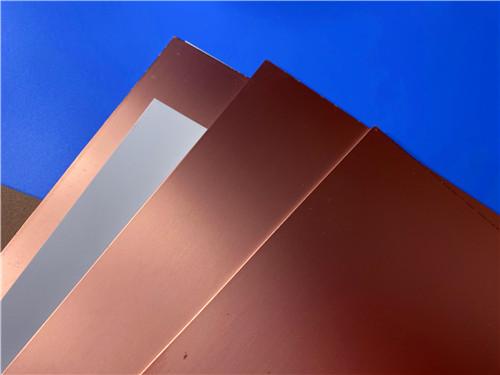

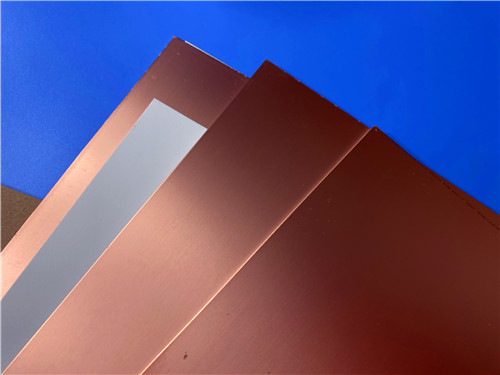

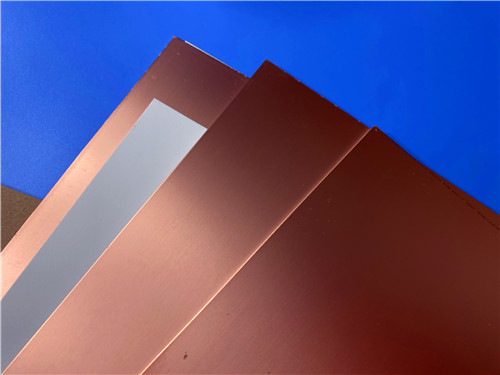

F4BME217 F4BME Series 0.2mm-12mm ThickCopper Clad Laminate Reversed RTF Copper Foil

1.Product Description

Wangling F4BME217 is a high-performance PTFE glass fiber cloth copper-clad laminate developed by Taizhou Wangling Insulation Material Factory. It is fabricated through scientific formulation and rigorous process compression using glass fiber cloth, polytetrafluoroethylene (PTFE) resin, and PTFE film. Compared with conventional F4B laminates, F4BME217 substrate offers enhanced electrical performance, featuring a wider dielectric constant range, lower dielectric loss, higher insulation resistance, and superior stability. It is fully capable of replacing equivalent foreign products in various high-end applications.

Distinguished by its matching copper foil, F4BME217 Wangling laminate adopts reversed RTF copper foil, which endows the product with excellent PIM (Passive Intermodulation) performance, more precise circuit control capabilities, and reduced conductor loss. This design makes it particularly suitable for scenarios requiring strict PIM index control. Additionally, the dielectric constant of F4BME217 material is precisely adjusted by optimizing the ratio between PTFE and glass fiber cloth, achieving both low loss and improved dimensional stability.

2. Product Features

Dielectric constant (DK) of 2.17 (typical value at 10GHz), with customizable options available

Exceptional low-loss performance, ensuring reliable signal transmission

Equipped with reversed RTF copper foil, delivering outstanding PIM indicators

Diversified size options to meet specific application needs and optimize cost efficiency

Radiation resistance and low outgassing properties, adapting to harsh operating environments

Commercialized, mass-produced, and cost-effective, suitable for large-scale applications

3. Technical Parameters Table

|

Product Characteristic

|

Test Condition

|

Unit

|

F4BME217 Specification

|

|

Dielectric Constant (Typical Value)

|

10GHz

|

/

|

2.17

|

|

Dielectric Constant Tolerance

|

/

|

/

|

±0.04

|

|

Loss Factor (Typical Value)

|

10GHz

|

/

|

0.001

|

|

Loss Factor (Typical Value)

|

20GHz

|

/

|

0.0014

|

|

Dielectric Constant Temperature Coefficient

|

-55℃~150℃

|

PPM/℃

|

-150

|

|

Peel Strength (1 OZ)

|

/

|

N/mm

|

>1.6

|

|

Volume Resistivity

|

Normal Condition

|

MΩ.cm

|

≥6×10⁶

|

|

Surface Resistivity

|

Normal Condition

|

MΩ

|

≥1×10⁶

|

|

Electrical Strength (Z-direction)

|

5KW, 500V/s

|

KV/mm

|

>23

|

|

Breakdown Voltage (XY-direction)

|

5KW, 500V/s

|

KV

|

>30

|

|

Coefficient of Thermal Expansion (CTE) - XY Direction

|

-55℃~288℃

|

ppm/℃

|

25-34

|

|

Coefficient of Thermal Expansion (CTE) - Z Direction

|

-55℃~288℃

|

ppm/℃

|

240

|

|

Thermal Stress

|

260℃, 10s, 3 cycles

|

/

|

No Delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm³

|

2.17

|

|

Long-term Operating Temperature

|

/

|

℃

|

-55~+260

|

|

Thermal Conductivity (Z-direction)

|

/

|

W/(M.K)

|

0.24

|

|

PIM Value

|

Applicable for F4BME Series

|

dBc

|

≤-159

|

|

Flame Retardancy

|

/

|

UL-94

|

V-0

|

|

Material Composition

|

/

|

/

|

PTFE, glass fiber cloth

F4BM is paired with ED copper foil, and F4BME is paired with reversed RTF copper foil

|

4. Optional Copper Foil

F4BME217 is exclusively paired with reversed RTF copper foil, with the following optional thicknesses:

0.5OZ (0.018mm)

1OZ (0.035mm)

5. Available Sizes

5.1 Standard Sizes

460×610mm, 500×600mm, 850×1200mm, 914×1220mm, 1000×1200mm

5.2 Custom Sizes

300×250mm, 350×380mm, 500×500mm, 840×840mm, 1000×1500mm (contact us for other special sizes)

5.3 Note

When the thickness is≥4.0mm or≤0.2mm, the maximum size shall not exceed 500×610mm.

6. Thickness and Tolerance

|

Thickness Type

|

Thickness (mm)

|

Tolerance (mm)

|

|

Dielectric Thickness (Minimum)

|

0.1 (since DK≤2.65)

|

±0.01

|

|

Standard Thickness (Including Copper)

|

0.2

|

±0.02

|

|

Standard Thickness (Including Copper)

|

0.25

|

±0.02

|

|

Standard Thickness (Including Copper)

|

0.5

|

±0.04

|

|

Standard Thickness (Including Copper)

|

0.508

|

±0.04

|

|

Standard Thickness (Including Copper)

|

0.762

|

±0.05

|

|

Standard Thickness (Including Copper)

|

0.8

|

±0.05

|

|

Standard Thickness (Including Copper)

|

1

|

±0.05

|

|

Standard Thickness (Including Copper)

|

1.5

|

±0.06

|

|

Standard Thickness (Including Copper)

|

1.524

|

±0.06

|

|

Standard Thickness (Including Copper)

|

1.575

|

±0.06

|

|

Standard Thickness (Including Copper)

|

2

|

±0.08

|

|

Standard Thickness (Including Copper)

|

2.5

|

±0.08

|

|

Standard Thickness (Including Copper)

|

3

|

±0.09

|

|

Standard Thickness (Including Copper)

|

4

|

±0.1

|

|

Standard Thickness (Including Copper)

|

5

|

±0.1

|

|

Standard Thickness (Including Copper)

|

6

|

±0.12

|

|

Standard Thickness (Including Copper)

|

8

|

±0.15

|

|

Standard Thickness (Including Copper)

|

10

|

±0.18

|

|

Standard Thickness (Including Copper)

|

12

|

±0.2

|

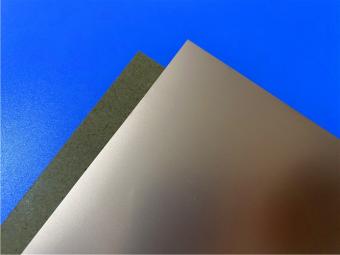

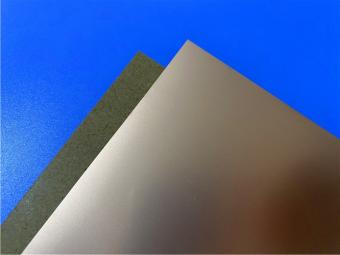

7. Aluminum/Copper Clad Substrates (Optional)

F4BME217 is available in aluminum-clad or copper-clad versions, designed with one side of the dielectric layer covered with copper foil and the other side with aluminum or copper base for shielding or heat dissipation purposes.

|

Model

|

Metal Base Material

|

Specific Gravity

|

Thermal Conductivity (W/(M.K))

|

Available Metal Base Thickness (mm)

|

Metal Base Thickness Tolerance (mm)

|

Available Sizes (mm)

|

|

F4BME217-AL

|

Aluminum

|

2.7

|

180

|

Customizable (contact for details)

|

/

|

460×610, 460×305 (custom sizes available)

|

|

F4BME217-CU

|

Red Copper/Brass

|

8.9

|

380

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (other thicknesses customizable)

|

+0.02, -0.05

|

460×610, 460×305 (custom sizes available)

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com