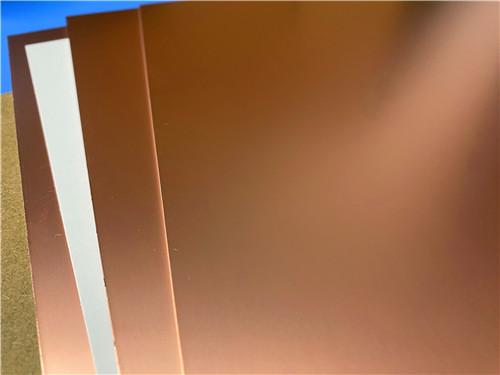

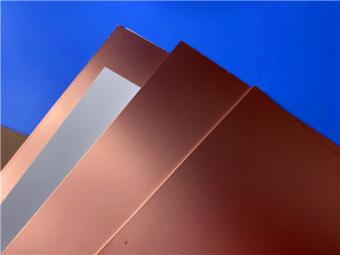

Rogers DiClad 880 0.508mm 0.762mm 1.524 mm PTFE Woven Fiberglass Copper Clad Laminate

DiClad 880 Laminate is a high-performance woven fiberglass/PTFE composite laminate designed for use as a printed circuit board substrate. It offers an excellent balance of electrical and mechanical properties, making it suitable for demanding high-frequency applications. The woven fiberglass reinforcement provides superior dimensional stability and uniform dielectric properties compared to non-woven reinforced PTFE laminates of similar dielectric constant.

With its controlled PTFE-to-fiberglass ratio, DiClad 880 substrate delivers consistent electrical performance across a wide frequency range, along with excellent chemical resistance and mechanical reliability. It is particularly well-suited for applications where low loss, signal integrity, and stable electrical characteristics are critical.

Key Features & Benefits:

1) Extremely Low Loss Tangent–Minimizes signal attenuation in high-frequency circuits.

2) Excellent Dimensional Stability–Maintains shape and alignment under thermal and mechanical stress.

3) High Uniformity of Dielectric Constant–Consistent electrical behavior across the substrate and over frequency.

4) Stable Dissipation Factor vs. Frequency–Ensures reliable performance in broadband and multi-band designs.

5) Strong Mechanical Performance–Good tensile and flexural strength for reliable assembly and use.

6) Superior Chemical Resistance–Withstands harsh processing and operating environments.

Typical Applications

Military Radar Feed Networks

Commercial Phased Array Antennas

Low-Loss Base Station Antennas

Missile Guidance Systems

Digital Radio Antennas

Filters, Couplers, and Low-Noise Amplifiers (LNAs)

Standard Properties of DiClad 880

|

Properties

|

Typical Value

|

Units

|

Test Conditions

|

Test Method

|

|

Electrical Properties

|

|

Dielectric Constant @ 10 GHz

|

2.17, 2.20

|

–

|

23°C @ 50% RH

|

IPC TM-650 2.5.5.5

|

|

Dielectric Constant @ 1 MHz

|

2.17, 2.20

|

–

|

23°C @ 50% RH

|

IPC TM-650 2.5.5.3

|

|

Dissipation Factor @ 10 GHz

|

0.0009

|

–

|

23°C @ 50% RH

|

IPC TM-650 2.5.5.5

|

|

Dissipation Factor @ 1 MHz

|

0.0008

|

–

|

23°C @ 50% RH

|

IPC TM-650 2.5.5.3

|

|

Thermal Coefficient of Dielectric Constant

|

-160

|

ppm/°C

|

-10 to 140°C @ 10 GHz

|

IPC TM-650 2.5.5.5

|

|

Volume Resistivity

|

1.4 × 10⁹

|

MΩ·cm

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity

|

2.9 × 10⁸

|

MΩ

|

C96/35/90

|

IPC TM-650 2.5.17.1

|

|

Dielectric Breakdown

|

>45

|

kV

|

D48/50

|

ASTM D-149

|

|

Arc Resistance

|

>180

|

s

|

–

|

ASTM D-495

|

|

Thermal Properties

|

|

CTE – x

|

25

|

ppm/°C

|

50°C to 150°C

|

IPC TM-650 2.4.4.1

|

|

CTE – y

|

34

|

ppm/°C

|

50°C to 150°C

|

IPC TM-650 2.4.4.1

|

|

CTE – z

|

252

|

ppm/°C

|

50°C to 150°C

|

IPC TM-650 2.4.4.2

|

|

Thermal Conductivity

|

0.25

|

W/(m·K)

|

–

|

ASTM E1461

|

|

Mechanical Properties

|

|

Copper Peel Strength

|

14

|

lbs/in

|

10s @ 288°C, 35µm foil

|

IPC TM-650 2.4.8

|

|

Young's Modulus (MD, CMD)

|

267, 202

|

kpsi

|

23°C @ 50% RH

|

ASTM D-638

|

|

Tensile Strength (MD, CMD)

|

8.1, 7.5

|

kpsi

|

23°C @ 50% RH

|

ASTM D-882

|

|

Compressive Modulus

|

237

|

kpsi

|

23°C @ 50% RH

|

ASTM D-695

|

|

Flexural Modulus

|

357

|

kpsi

|

23°C @ 50% RH

|

ASTM D-3039

|

|

Physical Properties

|

|

Flammability

|

V-0

|

–

|

C48/23/50 & C168/70

|

UL 94

|

|

Moisture Absorption

|

0.02

|

%

|

E1/105 + D24/23

|

IPC TM-650 2.6.2.2

|

|

Density

|

2.23

|

g/cm³

|

C24/23/50

|

ASTM D792

|

|

Total Mass Lost (TML)

|

0.01

|

%

|

125°C, ≤10⁻⁶ torr

|

NASA SP-R-0022A

|

|

Collected Volatiles (CV)

|

0.01

|

%

|

125°C, ≤10⁻⁶ torr

|

NASA SP-R-0022A

|

|

Water Vapor Recovered (WVR)

|

0

|

%

|

125°C, ≤10⁻⁶ torr

|

NASA SP-R-0022A

|

Standard Offerings–DiClad 880

|

Standard Thickness

|

Tolerance

|

Standard Panel Sizes

|

Standard Claddings

|

|

|

0.020″ (0.508 mm)

|

±0.0020″

|

12″ × 18″ (305 × 457 mm)

|

Electrodeposited Copper Foil

|

|

|

0.030″ (0.762 mm)

|

±0.0020″

|

18″ × 12″ (457 × 305 mm)

|

½ oz (18 µm)

|

|

|

0.060″ (1.524 mm)

|

±0.0020″

|

18″ × 24″ (457 × 610 mm)

|

1 oz (35 µm)

|

|

|

|

|

24″ × 18″ (610 × 457 mm)

|

|

Other thicknesses, panel sizes, and cladding options are available upon request.

Note:All data is based on controlled laboratory testing and is subject to normal manufacturing variances. Specifications may be updated without prior notice.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com