Wangling F4BM220 DK2.2 PTFE Glass Fiber Reinforced Copper Clad Laminate

Product Overview:

The F4BM220 copper clad laminate is a high-performance PTFE glass fiber reinforced copper clad laminate engineered for advanced microwave and RF applications. It is fabricated through a precise formulation and strict manufacturing process utilizing glass fiber cloth, polytetrafluoroethylene (PTFE) resin, and PTFE film. This material offers enhanced electrical properties compared to standard F4B substrates, including a broader range of achievable dielectric constants, lower dissipation factor, increased insulation resistance, and improved stability, making it a suitable alternative to equivalent international products.

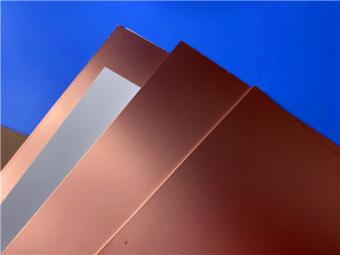

The F4BM series laminates utilizes ED (Electrodeposited) copper foil, making it an optimal choice for applications where Passive Intermodulation (PIM) performance is not a critical specification.

A key feature of the F4BM series substrate is the ability to precisely tune the dielectric constant by adjusting the ratio of PTFE to glass fiber. This allows for optimal balancing of low signal loss and enhanced dimensional stability. For the F4BM220 , a higher glass fiber content contributes to its excellent dimensional stability, lower coefficient of thermal expansion (CTE), improved temperature stability, and a marginally higher dissipation factor compared to lower-Dk variants.

Product Features:

Dielectric Constant (Dk): 2.20 (Typical, @ 10 GHz)

Low Loss: Excellent signal integrity for high-frequency designs.

Cost-Effective Sizing: Available in multiple standard and custom panel sizes to minimize waste.

Environmental Resistance: Features low outgassing and resistance to radiation.

High Volume & Commercial Grade: Produced reliably in large quantities offering excellent cost-performance ratio.

Application Fields

F4BM220 DK2.2 laminate is widely utilized in high-frequency and high-speed electronic systems, including but not limited to:

Microwave, radio frequency (RF), and radar systems

Phase shifters and passive components

Power dividers, couplers, and combiners

Feeding networks and phased array antennas

Satellite communications and base station antennas

F4BM220 Technical Specifications

|

Product Characteristic

|

Test Condition

|

Unit

|

F4BM220 Data

|

|

Dielectric Constant (Typ.)

|

10 GHz

|

-

|

2.2

|

|

Dk Tolerance

|

-

|

-

|

±0.04

|

|

Dissipation Factor (Typ.)

|

10 GHz

|

-

|

0.001

|

|

20 GHz

|

-

|

0.0014

|

|

|

Temperature Coefficient of Dk

|

-55°C ~ 150°C

|

ppm/°C

|

-142

|

|

Peel Strength

|

1 oz ED Copper

|

N/mm

|

>1.8

|

|

Volume Resistivity

|

Ambient

|

MΩ·cm

|

≥6 x 10⁶

|

|

Surface Resistance

|

Ambient

|

MΩ

|

≥1 x 10⁶

|

|

Dielectric Strength (Z-axis)

|

5kV, 500V/s

|

kV/mm

|

>23

|

|

Breakdown Voltage (XY-plane)

|

5kV, 500V/s

|

kV

|

>30

|

|

Coeff. of Thermal Expansion (CTE)

|

XY, -55°C~288°C

|

ppm/°C

|

25~34

|

|

Z, -55°C~288°C

|

ppm/°C

|

240

|

|

|

Thermal Stress

|

260°C, 10s, 3 cycles

|

-

|

No Delamination

|

|

Water Absorption

|

20±2°C, 24 hours

|

%

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm³

|

2.18

|

|

Long-term Operating Temp

|

High-Low Temperature Chamber

|

°C

|

-55 to +260

|

|

Thermal Conductivity (Z-axis)

|

Z direction

|

W/(m·K)

|

0.24

|

|

Flame Retardancy

|

-

|

UL-94

|

V-0

|

|

Material Composition

|

-

|

-

|

PTFE, Woven Glass Fiber, ED Copper Foil

|

Copper Foil Thickness

F4BM220 is available with ED copper foil in the following thicknesses:

0.5OZ (0.018mm)

1OZ (0.035mm)

1.5OZ (0.05mm)

2OZ (0.07mm)

Panel Sizes

Standard Sizes

460x610mm, 500x600mm, 850x1200mm, 914x1220mm, 1000x1200mm

Custom Sizes

300x250mm, 350x380mm, 500x500mm, 840x840mm, 1000x1500mm (contact us for other custom dimensions)

Remark: For panels with thickness≥4.0mm or≤0.2mm, the maximum size is limited to 500x610mm.

Thickness & Tolerance (Dielectric or Total Thickness with Copper)

|

Thickness (mm)

|

Tolerance (mm)

|

Thickness (mm)

|

Tolerance (mm)

|

Thickness (mm)

|

Tolerance (mm)

|

|

0.1 (Dielectric)

|

±0.01

|

0.8

|

±0.05

|

3

|

±0.09

|

|

0.127 (Dielectric)

|

±0.01

|

1

|

±0.05

|

4

|

±0.1

|

|

0.2

|

±0.02

|

1.5

|

±0.06

|

5

|

±0.1

|

|

0.25

|

±0.02

|

1.524

|

±0.06

|

6

|

±0.12

|

|

0.5

|

±0.04

|

1.575

|

±0.06

|

8

|

±0.15

|

|

0.508

|

±0.04

|

2

|

±0.08

|

10

|

±0.18

|

|

0.762

|

±0.05

|

2.5

|

±0.08

|

12

|

±0.2

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com