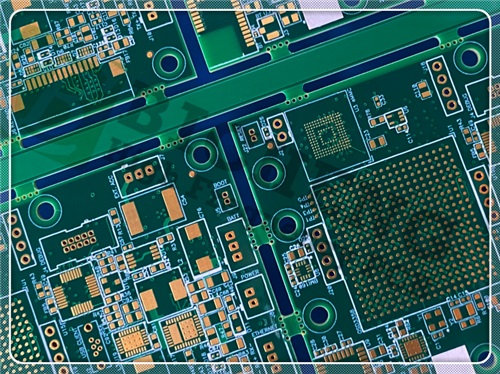

HDI Hybrid PCB Blind Via 8-Layer 1.5mm RO4003C Shengyi S10002M Material Circuit Board

Introduction

Introducing our HDI Hybrid PCB 8-Layer 1.5mm RO4003C S10002M, a cutting-edge printed circuit board designed to meet the demands of high-frequency applications. This exceptional PCB combines the performance advantages of Rogers RO4003C material and FR-4 S1000-2M, offering superior electrical properties and cost-effective fabrication. With its advanced features and top-notch specifications, our HDI Hybrid PCB is poised to revolutionize the world of RF microwave circuits, matching networks, and controlled impedance transmission lines.

Basic PCB Specifications

|

Specifications

|

Values

|

|

Board type

|

8 layers

|

|

Material type

|

RO4003C + FR-4 Tg170 'C

|

|

Solder mask

|

Both sides, Green

|

|

Silkscreen print

|

Top side, white

|

|

Surface finish

|

ENIG

|

|

Total board thickness

|

1.5mm +/- 10%

|

|

Board size

|

87.5mm x 40.6mm (1 PCS)

|

|

Minimum hole size

|

0.2mm

|

|

Solder mask thickness

|

10um

|

|

Minimum dielectric thickness

|

100um

|

|

Minimum trace line width

|

115um

|

|

Minimum spacing

|

135um

|

|

Blind via

|

L1-L2, L7-L8

|

|

Buried via

|

L2-L7

|

|

Back drilled via

|

L1-L6

|

|

All 0.3mm vias are filled and capped

|

According to IPC 4761 Type VII

|

|

Edge plating is required

|

|

Impedance Controlled:

|

Impedance

|

Type

|

Trace Width/Gap (mil)

|

Reference Layer

|

|

50 ohm

|

Differential pairs, Top layer

|

4/4

|

Layer 2

|

|

100 ohm

|

Differential pairs, Top layer

|

5/6

|

Layer 2

|

|

50 ohm

|

Single end, Top layer

|

6

|

Layer 2

|

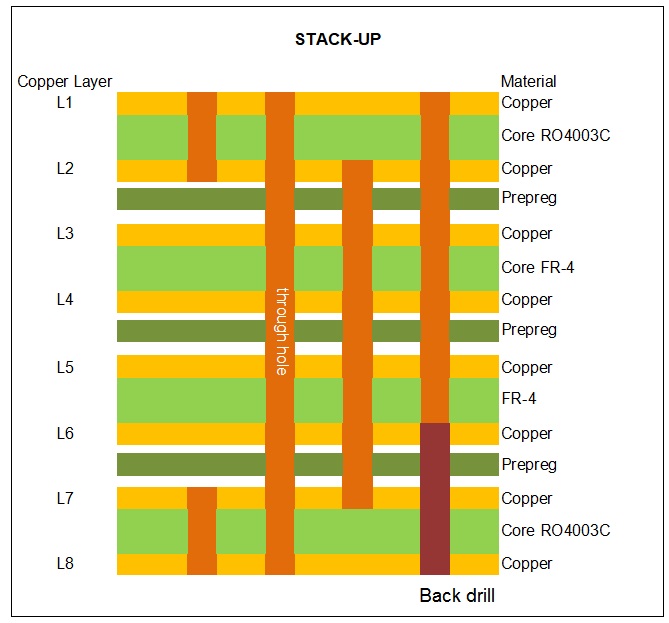

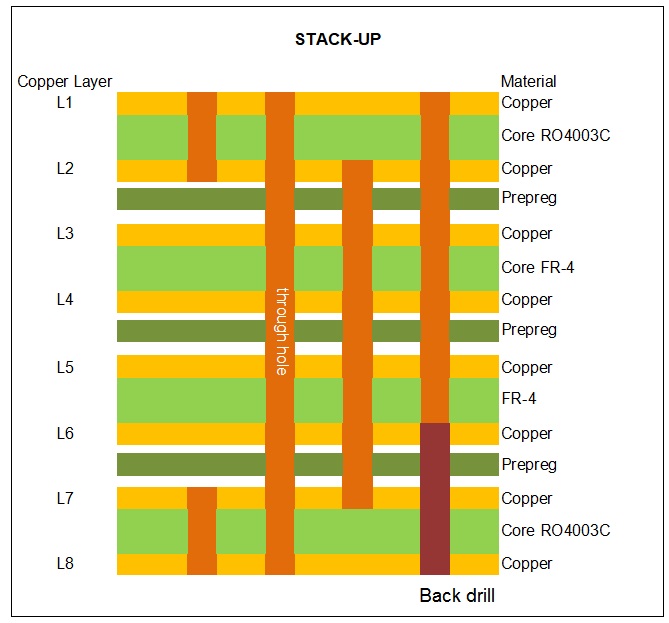

PCB Stack-Up

This HDI Hybrid PCB features a carefully designed stack-up that optimizes signal integrity and thermal management. The board consists of copper layers, Rogers 4003C and FR-4 materials that offer excellent electrical performance and stability. The stack-up is listed as follows:

|

TYPE

|

LAYER NO.

|

THICKNESS(um)

|

SPECIFICATION

|

|

COPPER

|

1

|

45

|

18um BASE COPPER + 25um PLATING

|

|

RO4003C CORE

|

|

203

|

IPC-4101/24

|

|

COPPER

|

2

|

38

|

|

|

FR-4 PP

|

|

100

|

IPC-4101/24

|

|

COPPER

|

3

|

17

|

|

|

FR-4 S1000-2M

|

|

240

|

IPC-4101/24

|

|

COPPER

|

4

|

35

|

|

|

FR-4 PP

|

|

100

|

IPC-4101/24

|

|

COPPER

|

5

|

35

|

|

|

FR-4 S1000-2M

|

|

240

|

IPC-4101/24

|

|

COPPER

|

6

|

17

|

|

|

FR-4 PP

|

|

100

|

IPC-4101/24

|

|

COPPER

|

7

|

38

|

|

|

RO4003C CORE

|

|

200

|

IPC-4101/24

|

|

COPPER

|

8

|

45

|

18um BASE COPPER + 25um PLATING

|

This carefully engineered 8 layer stack-up delivers optimal performance, ensuring efficient signal transmission and heat dissipation.

PCB Statistics

This HDI material Hybrid PCB boasts impressive statistics displaying its capabilities.

|

PCB Statistics

|

Count

|

|

Components

|

41

|

|

Total Pads

|

73

|

|

Thru Hole Pads

|

35

|

|

Top SMT Pads

|

26

|

|

Bottom SMT Pads

|

12

|

|

Vias

|

57

|

|

Nets

|

6

|

Artwork and Quality Standard

We provide Gerber RS-274-X files as the standard artwork for HDI hybrid circuit board. These files contain the necessary information for fabrication and assembly, ensuring seamless integration with your manufacturing processes. Furthermore, our PCB adheres to the IPC-Class-2 quality standard, guaranteeing reliable performance and durability.

Availability

HDI Hybrid PCB Material is available for worldwide distribution, allowing customers from around the globe to access this cutting-edge technology for their projects. Whether you're located in North America, Europe, Asia, or any other region, our PCB can be shipped and delivered to your doorstep.

Introduction to RO4003C

RO4003C, a proprietary material from Rogers, combines woven glass reinforcement with hydrocarbon/ceramics, harnessing the benefits of PTFE/woven glass and epoxy/glass laminates. This unique composition offers superior high-frequency performance while maintaining cost-effective fabrication processes. The result is a low-loss material capable of meeting the demands of RF microwave circuits, matching networks, and controlled impedance transmission lines.

RO4003C Substrate are available in various configurations, all featuring outstanding electrical performance according to IPC-4101/24 standards. By utilizing non-brominated materials and exempting UL 94 V-0 rating, RO4003C ensures enhanced safety and compliance.

RO4003C Features

Rogers RO4003C High Frequency PCB comes with a range of exceptional features that make it the material of choice for high-frequency applications:

1.Dielectric Constant (DK) of 3.38 +/- 0.05 at 10GHz:

RO4003C possesses a stable and predictable dielectric constant, enabling precise signal propagation, impedance control, and minimized signal distortion.

2.Dissipation Factor of 0.0027 at 10GHz:

This low dissipation factor ensures efficient power transmission while minimizing energy loss and signal degradation.

3.Thermal Conductivity of 0.71 W/m/°K:

Ideal for high-power applications, RO4003C effectively dissipates heat, providing excellent thermal management.

4.Thermal Coefficient of Dielectric Constant at +40 ppm/°C (ranging from -50°C to 150°C):

RO4003C exhibits excellent thermal stability, ensuring consistent performance across a wide temperature range.

5.CTE (Coefficient of Thermal Expansion) matched to copper with an X-axis of 11ppm/°C and Y-axis of 14ppm/°C:

This matching coefficient mitigates stress and thermal expansion mismatches, minimizing the risk of via failure and ensuring long-term reliability.

6.Low Z-axis CTE of 46 ppm/°C:

The low coefficient of thermal expansion in the Z-axis direction enhances dimensional stability and reliability.

7.Tg (Glass Transition Temperature) >280°C:

RO4003C can withstand high-temperature environments, making it suitable for demanding applications where heat dissipation is critical.

8.Low Moisture Absorption of 0.06%:

With minimal moisture absorption, RO4003C maintains electrical and mechanical stability, ensuring consistent performance over time.

Introduction to S1000-2M

FR-4 S1000-2M is a high-performance material known for its exceptional thermal and electrical properties. It boasts a low Z-axis coefficient of thermal expansion (CTE), high-temperature resistance, and flame retardancy. These characteristics make it a reliable choice for circuit boards that require high reliability and resilience.

S1000-2M Features

FR-4 S1000-2M offers several features that make it an ideal material for our HDI Hybrid PCB:

1.Low Z-axis CTE of 2.4 ppm/℃:

The low coefficient of thermal expansion ensures stable performance and prevents issues related to differential expansion between materials, such as via barrel cracking and delamination.

2.High Tg (Glass Transition Temperature) of 185℃:

Shengyi S1000-2M can withstand elevated temperatures, providing excellent heat resistance and dimensional stability in demanding applications.

3.Low Water Absorption of 0.08%:

With minimal water absorption, FR-4 S1000-2M maintains its electrical properties even in humid environments, ensuring reliable performance.

4.T260 of 60 minutes, T288 of 30 minutes:

The material's ability to withstand high temperatures for extended periods allows it to endure the rigorous demands of modern assembly processes.

5.UL 94-V0 Flammability Rating:

FR-4 S1000-2M is a flame-retardant material that offers enhanced safety and complies with industry standards.

Typical Applications

The HDI Hybrid multilayer printed circuit board finds numerous applications in various industries that require high-frequency performance, reliability, and advanced PCB technologies, including:

- Cellular Base Station Antennas and Power Amplifiers

- RF Identification Tags

- Automotive Radar and Sensors

- LNB's for Direct Broadcast Satellites

- Computing, communication, automotive electronics

Conclusion

In conclusion,The HDI Hybrid PCB 8-Layer 1.5mm RO4003C S10002M combines advanced technologies and materials to provide exceptional electrical performance, reliability, and cost-effectiveness. With its innovative stack-up and impressive features, this HDI board meets the demands of high-frequency applications.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com