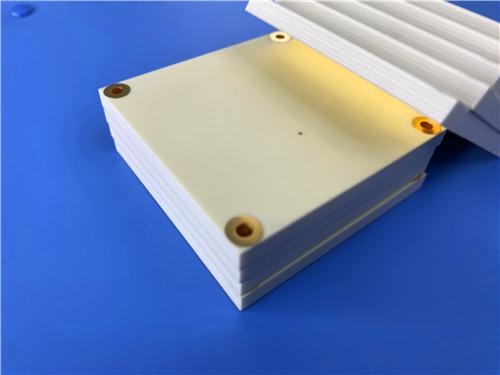

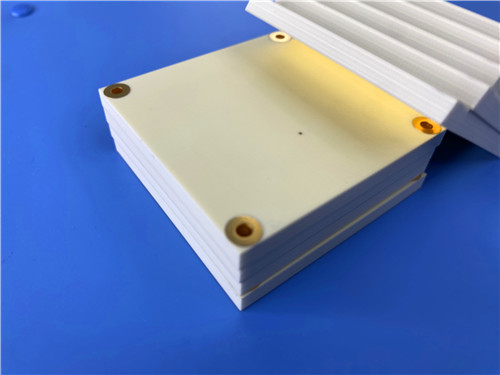

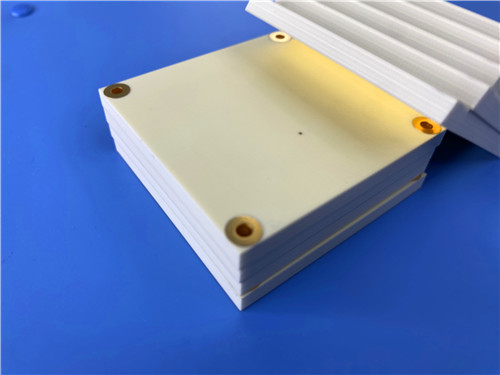

RO4003C PCB 4-layerRogers 4003C Multi-layerENIG CountersunkHoles and Filled Resin

Introduction

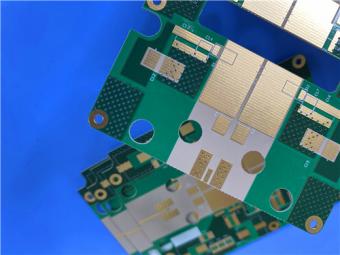

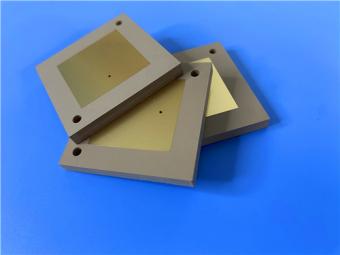

The RO4003C 4-Layer ENIG PCB with Countersunk Holes is engineered to meet the demands of performance-sensitive RF, microwave, and high-frequency applications. Built with Rogers’proprietaryRO4003C laminate—a woven glass-reinforced hydrocarbon/ceramic material—it delivers PTFE-level electrical performance (low loss, stable dielectric constant) while matching the manufacturability and cost-efficiency of standard epoxy/glass (FR-4) PCBs. This combination makes it ideal for high-volume projects like cellular base stations, automotive radar, and RFID tags, where signal integrity, thermal stability, and cost control are critical. Below is a details of its specifications, construction, and benefits.

Rogers RO4003C Material: The Foundation of Performance

At the core of this PCB is Rogers RO4003C, a non-brominated laminate designed to solve common pain points in microwave PCBs. Unlike PTFE-based materials, it requires no special through-hole treatments or handling, reducing fabrication complexity and cost. Key material advantages include:

1)Stable Electrical Performance:

Tight dielectric constant (Dk = 3.38±0.05 at 10GHz) and ultra-low dissipation factor (0.0027 at 10GHz, 0.0021 at 2.5GHz) ensure minimal signal loss—critical for high-frequency applications.

2)Thermal Reliability:

A glass transition temperature (Tg) >280°C maintains stability through all circuit processing steps, while a Z-axis coefficient of thermal expansion (CTE) of 46ppm/°C (similar to copper) guarantees reliable plated through-holes, even in severe thermal shock.

3)Dimensional Stability:

X/Y-axis CTE (11ppm/°C, 14ppm/°C) matches copper, preventing warpage in multi-layer constructions.

4)Low Moisture Absorption:

0.06% absorption minimizes performance degradation in humid environments.

1. PCB Construction Details

The table below outlines the core physical and manufacturing specifications, ensuring consistency and compatibility with end-use designs:

|

Feature

|

Specification

|

|

Base Material

|

Rogers RO4003C

|

|

Layer Count

|

4-Layer

|

|

Board Dimensions

|

60mm x 60mm (±0.15mm)

|

|

Min. Trace/Spacing

|

4 mil / 5 mil

|

|

Min. Hole Size

|

0.4mm

|

|

Blind/Buried Vias

|

No

|

|

Finished Thickness

|

4.8mm

|

|

Cu Weight (Inner/Outer)

|

1 oz (35 μm / 1.4 mils)

|

|

Via Plating Thickness

|

20 μm

|

|

Surface Finish

|

ENIG (Electroless Nickel Immersion Gold)

|

|

Top/Bottom Silkscreen

|

Black / None

|

|

Top/Bottom Solder Mask

|

None / None

|

|

Via Treatment

|

Filled with resin and capped

|

|

Countersunk Holes

|

Conical, 90-degree

|

|

Electrical Test

|

100% Tested

|

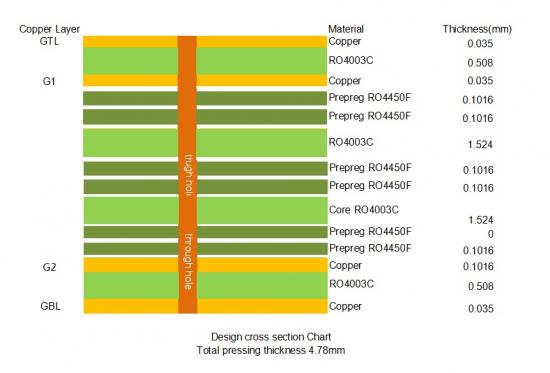

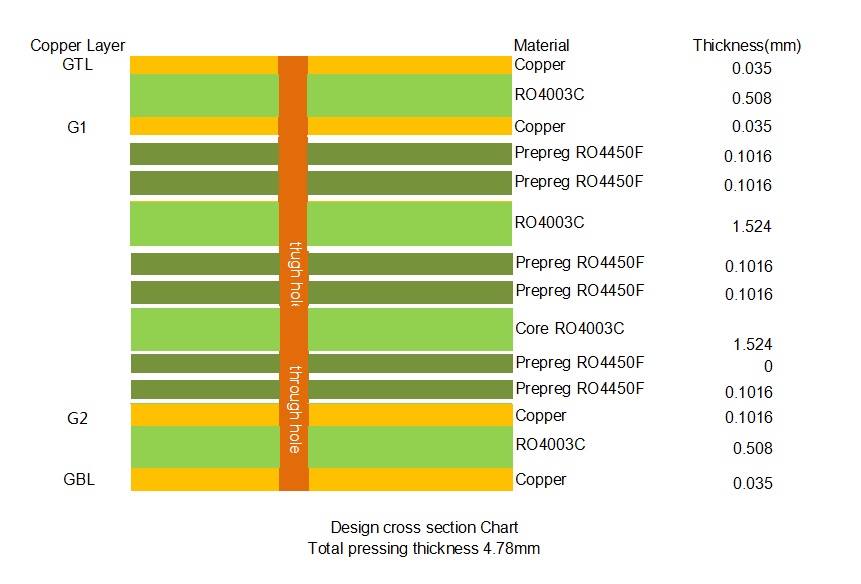

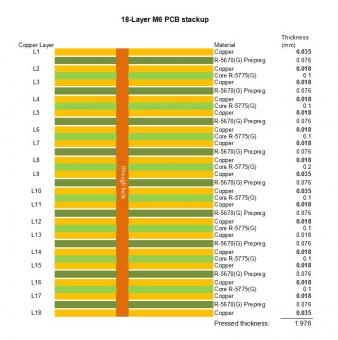

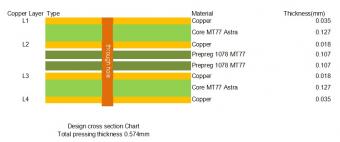

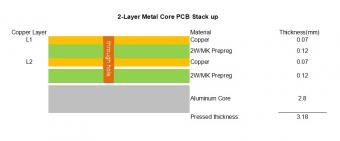

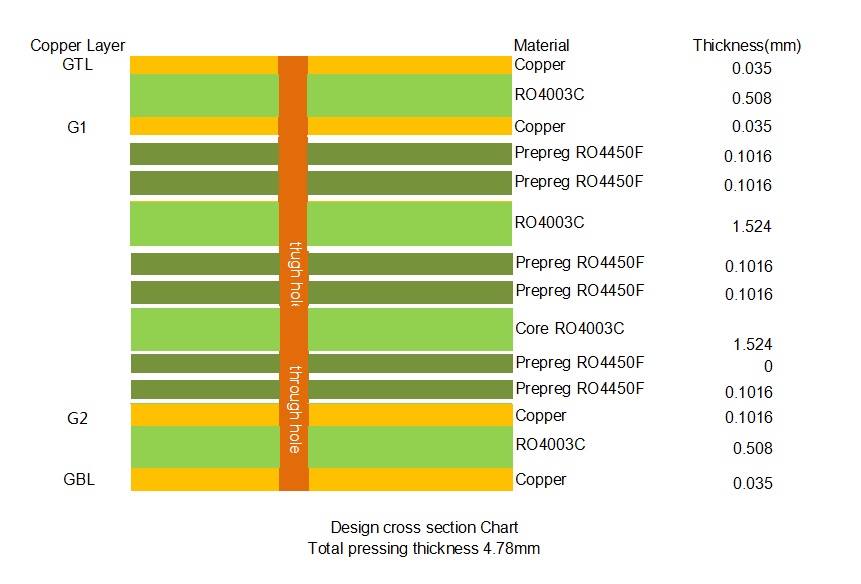

2. PCB Stackup

The 4-layer PCB stackup is precision-engineered to balance signal performance, thermal conductivity, and structural stability. Each layer’s material and thickness are selected to enhance electrical consistency:

|

Layer

|

Material

|

Thickness

|

|

Copper (Layer 1)

|

Foil

|

35 μm

|

|

Core

|

Rogers 4003C

|

0.508 mm (20 mil)

|

|

Copper (Layer 2)

|

Foil

|

35 μm

|

|

Prepreg

|

RO4450F (x2 sheets)

|

0.204 mm

|

|

Core

|

Rogers 4003C

|

1.524 mm (60 mil)

|

|

Prepreg

|

RO4450F (x2 sheets)

|

0.204 mm

|

|

Core

|

Rogers 4003C

|

1.524 mm (60 mil)

|

|

Prepreg

|

RO4450F (x2 sheets)

|

0.204 mm

|

|

Copper (Layer 3)

|

Foil

|

35 μm

|

|

Core

|

Rogers 4003C

|

0.508 mm (20 mil)

|

|

Copper (Layer 4)

|

Foil

|

35 μm

|

3. PCB Statistics

The table below summarizes key component and connection metrics to streamline design integration:

|

Item

|

Quantity

|

|

Components

|

2

|

|

Total Pads

|

7

|

|

Thru-Hole Pads

|

3

|

|

Top-SMT Pads

|

4

|

|

Bottom-SMT Pads

|

0

|

|

Vias

|

5

|

|

Nets

|

7

|

Benefits

1)Multi-Layer Versatility: Ideal for multi-layer board (MLB) constructions, thanks to dimensional stability and CTE matching.

2)Cost Efficiency: Processes like FR-4 (no special handling) at a fraction of conventional microwave PCB costs.

3)High-Volume Readiness: Designed for mass production without compromising performance.

Typical Applications

This 4-layer RO4003C PCB is the ideal solution for:

-

Automotive Radar and Collision Avoidance Systems

-

Cellular Base Station Antennas and Power Amplifiers

-

RF Identification (RFID) Tags

-

LNBs for Direct Broadcast Satellites

Quality & Availability

-

Quality Standard: Complies with IPC-Class 2 (industrial-grade reliability, suitable for most end-use applications).

-

Artwork Format: Accepts Gerber RS-274-X (industry-standard for PCB fabrication).

-

Global Availability: Shipped worldwide, ensuring timely access for international projects.

Conclusion

The Rogers RO4003C High Frequency PCB with Countersunk Holes bridges the gap between high performance and practicality. It leverages Rogers 4003C material to deliver microwave-grade electrical performance while remaining cost-competitive and easy to manufacture. Whether for automotive radar, cellular infrastructure, or RFID, this Rogers Multilayer PCB ensures reliability, signal integrity, and scalability—making it a standout choice for today’s performance-driven industries.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com