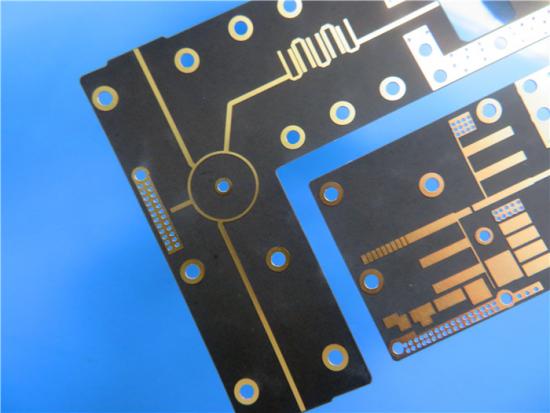

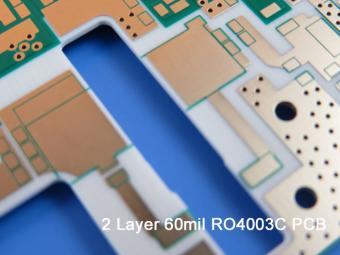

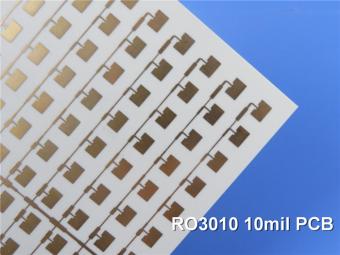

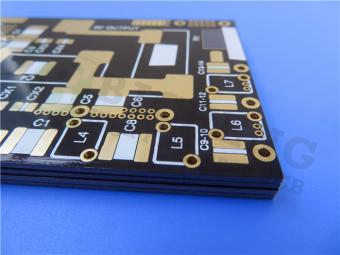

Rogers 3010 PCB RO3010 High Frequency PCB With

5mil, 10mil, 25mil and 50mil Coating Immersion Silver, Gold, Tin and HASL

(PCB's are custom-made products, the picture

and parameters shown are just for reference)

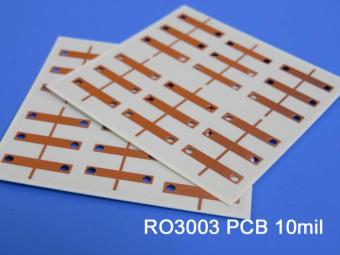

There is about RO3010 high frequency

PCBs.

RO3010 high frequency circuit laminates are

ceramic-filled PTFE composites intended for using in commercial microwave and

RF applications. Its obvious characteristic is that the electrical performance

is exceptional and the mechanical property is stable and consistent. Rogers RO3010 advanced circuit materials are ceramic-filled PTFE composites that offer a higher dielectric constant with excellent stability.

RO3010 laminates are competitively priced products with exceptional mechanical and electrical stability. This stability simplfes the design of broadband components and allows the

materials to be used in a wide range of applications over a very broad range of

frequencies. This material’s characteristics make RO3010 laminates excellent for circuit miniaturization.

More features

and applications are as follows:

1, Excellent

mechanical properties versus temperature, it’s reliable stripline and

multi-layer board constructions.

2, Uniform

mechanical properties, it’s suitable for use with epoxy glass multi-layer board

hybrid designs.

3, Low in-plane

expansion coefficient matches to copper, it allows for more reliable surface

mounted assemblies; ideal for applications sensitive to temperature change and

exhibit excellent dimensional stability.

OurPCB Capability

(RO3010)

|

PCB Material:

|

Ceramic-filled

PTFE composite

|

|

Designation:

|

RO3010

|

|

Dielectric

constant:

|

10. 2 ±0.3 (process)

|

|

11.2 (design)

|

|

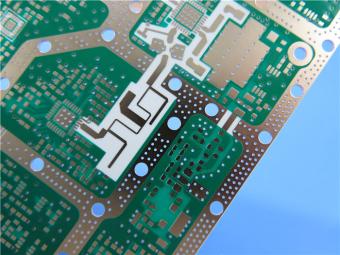

Layer count:

|

2 Layer,

Multilayer, Hybrid PCB

|

|

Copper weight:

|

0.5oz (17 µm),

1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

5mil (0.127mm),

10mil (0.254mm),

|

|

25mil (0.635mm),

50mil (1.27mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black,

Blue, Yellow, Red etc.

|

|

Surface finish:

|

Bare copper,

HASL, ENIG, OSP etc..

|

|

|

|

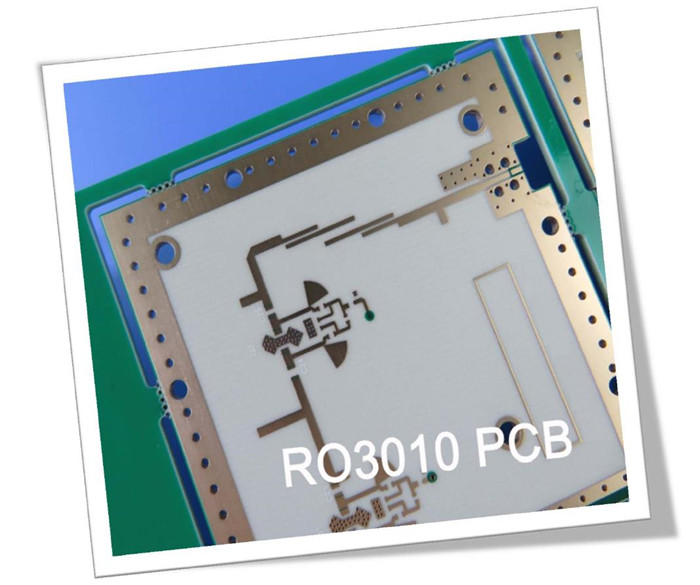

Double sided RO3010 high

frequency PCBs are also available with multi-layer and hybrid

construction, 0.5oz to 2oz finished copper, 0.13 mm to 1.3mm thick, maximum

size 400 mm by 500mm, surface finish with bare copper, hot air leveling,

immersion gold etc.

Typical

applications

1. Automotive

radar applications

2. GPS Antennas

3. Power

amplifiers and antennas

4. Patch

antennas for wireless communications

5. Direct

broadcast satellite

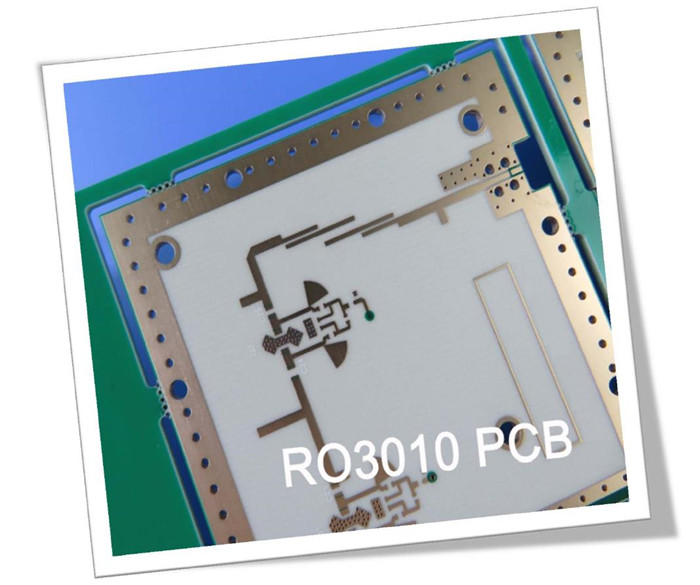

The basic colour of RO3010 PCB is white.

The manufacturing process of RO3010 high

frequency PCB is similar to standard PTFE PCB, so it’s suitable for volume

manufacturing process winning advantageous market.

Appendix: Data Sheet of RO3010

|

RO3010 Typical Value

|

|

Property

|

RO3010

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

10.2±0.05

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5 Clamped Stripline

|

|

Dielectric

Constant,εDesign

|

11.2

|

Z

|

|

8GHz to 40 GHz

|

Differential Phase

Length Method

|

|

Dissipation

Factor,tanδ

|

0.0022

|

Z

|

|

10

GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal

Coefficient of ε

|

-395

|

Z

|

ppm/℃

|

10 GHz -50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Dimensional

Stability

|

0.35

0.31

|

X

Y

|

mm/m

|

COND A

|

IPC-TM-650 2.2.4

|

|

Volume

Resistivity

|

105

|

|

MΩ.cm

|

COND A

|

IPC 2.5.17.1

|

|

Surface

Resistivity

|

105

|

|

MΩ

|

COND A

|

IPC 2.5.17.1

|

|

Tensile

Modulus

|

1902

1934

|

X

Y

|

MPa

|

23℃

|

ASTM D 638

|

|

Moisture

Absorption

|

0.05

|

|

%

|

D48/50

|

IPC-TM-650 2.6.2.1

|

|

Specific Heat

|

0.8

|

|

j/g/k

|

|

Calculated

|

|

Thermal

Conductivity

|

0.95

|

|

W/M/K

|

50℃

|

ASTM D 5470

|

Coefficient of Thermal Expansion

(-55 to 288℃)

|

13

11

16

|

X

Y

Z

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650 2.4.4.1

|

|

Td

|

500

|

|

℃TGA

|

|

ASTM D 3850

|

|

Density

|

2.8

|

|

gm/cm3

|

23℃

|

ASTM D 792

|

|

Copper Peel

Stength

|

9.4

|

|

Ib/in.

|

1oz,EDC After Solder

Float

|

IPC-TM 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free

Process Compatible

|

Yes

|

|

|

|

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com