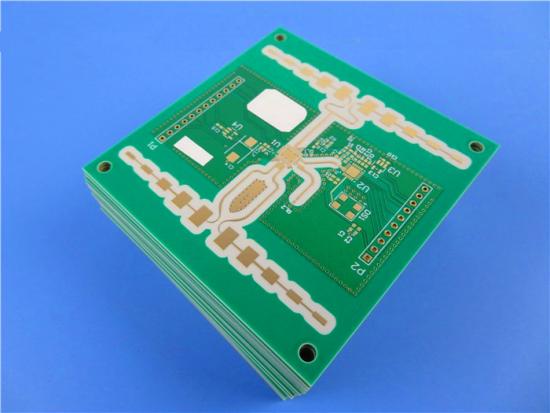

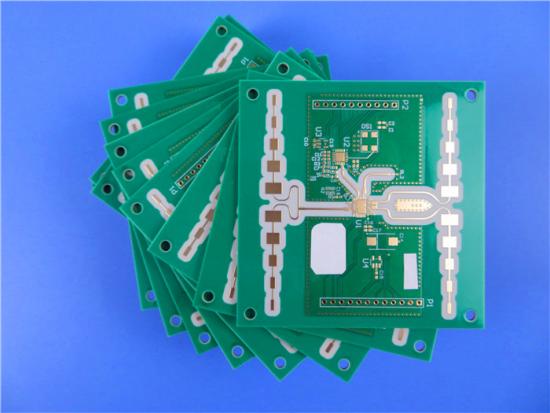

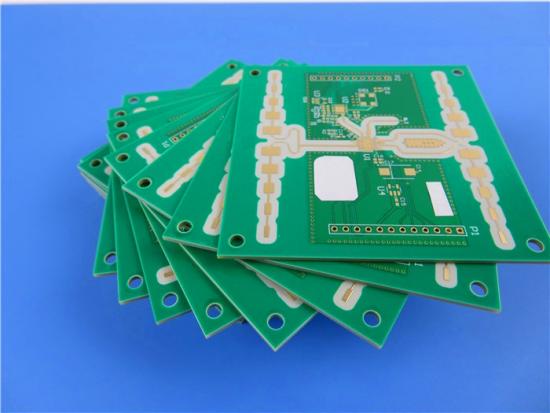

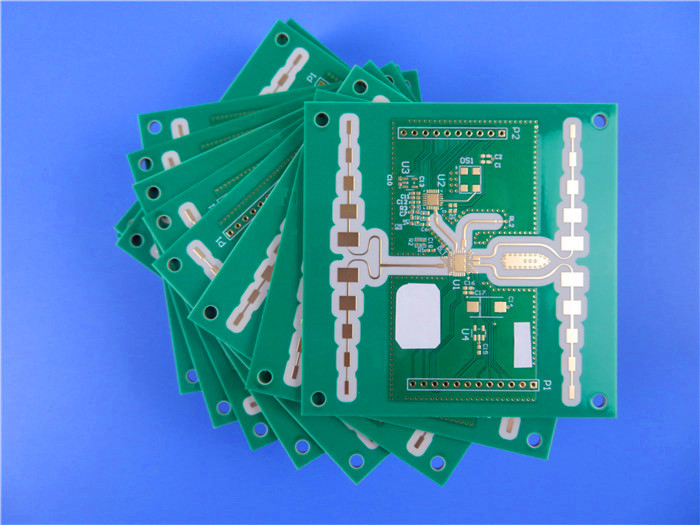

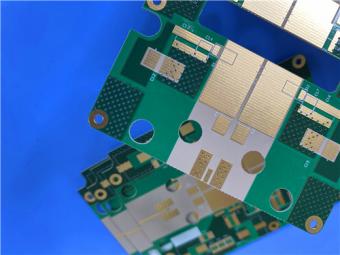

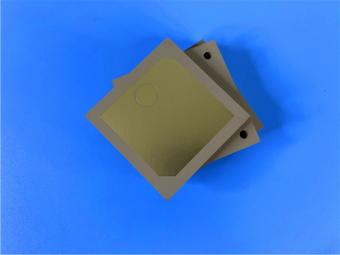

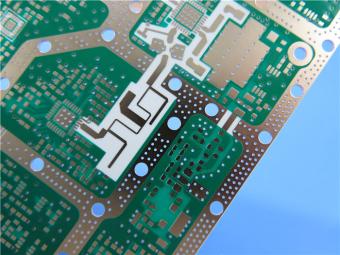

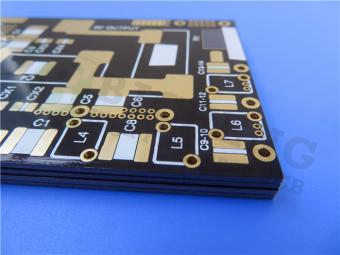

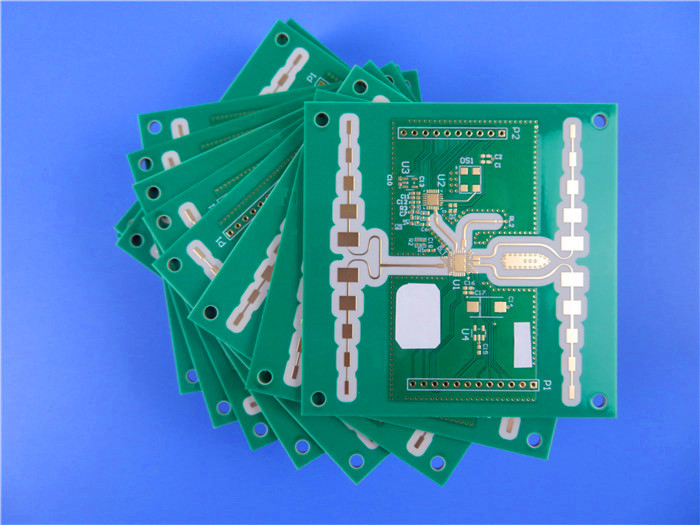

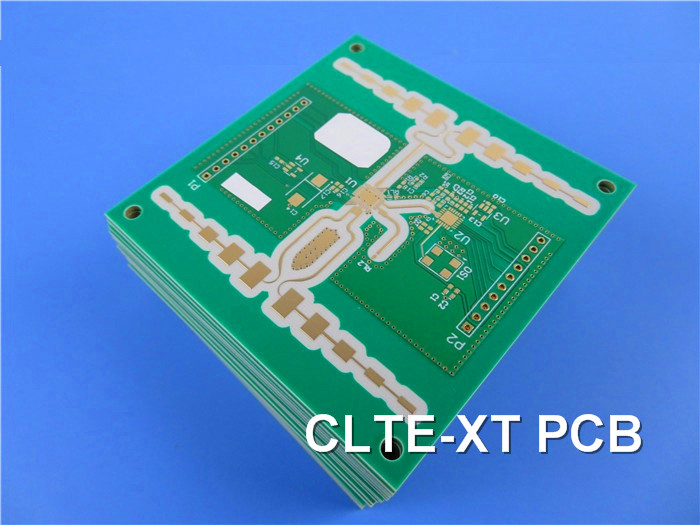

Rogers CLTE-XT High Frequency PCB 9.4mil 25mil 40mil 59mil

ceramic filled woven glass reinforced PTFE Circuit Boards

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

General Description

The CLTE-XT laminates are composites of PTFE, woven fiberglass reinforcement, CLTE-XT PCB and

micro-dispersed ceramic filler that are intended to increase loss tangent while

preserving good dimensional stability and offering excellent thermal

reliability and electrical performance.

Features and Benefits

1.Copper

matched CTE in X and Y axis

2.Low Z-direction

CTE of 20 ppm /°C

3.Low

dissipation factor of 0.0010 at 10 GHz reduced circuit losses without

sacrificing dimensional stability

4.Tightest

dielectric constant tolerance(+/- .03) and DK stability with temperature change

5.High

reliability on plated through holes

6.0.02% low

moisture absorption

7.Great number

of NASA outgassing values.

8.High thermal

conductivity of 0.56 W/m/K

Our PCB Capability (CLTE-XT laminates)

|

PCB Capability (CLTE-XT Laminates)

|

|

PCB material:

|

Ceramic/PTFE

Microwave Composite

|

|

Designation:

|

CLTE-XT

|

|

Dielectric constant:

|

2.94

|

|

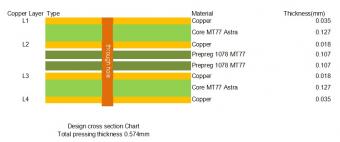

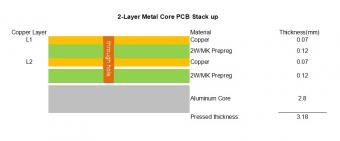

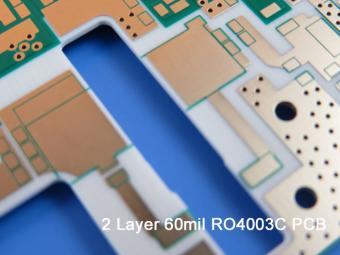

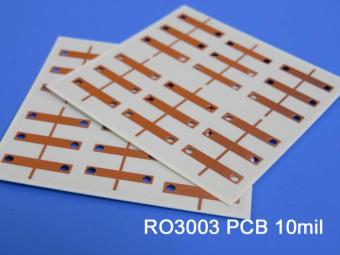

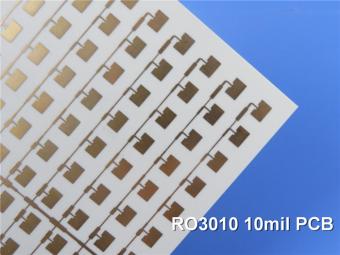

Layer count:

|

Sinlge-sided PCB, Double-sided

PCB, Multi-layer PCB, Hybrid PCB

|

|

Dielectric

thickness:

|

5.1mil(0.130mm),

9.4mil (0.239mm), 20mil (0.508mm), 25mil(0.635mm), 30mil(0.762mm),

40mil(1.016mm), 45mil(1.143mm), 59mil(1.499mm), 60mil(1.524mm)

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Red, Yellow etc.

|

|

Surface

finish:

|

Immersion

gold, HASL, Immersion silver, Immersion tin,Bare copper, OSP, Pure gold

plated etc..

|

The

majority of final finishes, including HASL, Sn, Ag, Ni/Au, OSP, etc., have been

applied to CLTE-XT materials without incident or cause for concern. Individual

circuit board can be routed, punched, or laser cut depending on preference,

tolerances, and edge quality requirements.

Typical Applications

1.

Advanced Driver Assistance Systems (ADAS)

2.

CNI (communication, navigation and identification) Applications

3.

Defense Microwave/RF Applications

4.

Microwave Feed Networks

5.

Phased Array Antennas

6.

Power Amplifiers

7.

Patch Antennas

8.

Radar Manifolds

9.

Satellite & Space Electronics

Data Sheet (CLTE-XT laminates)

|

Properties

|

CLTE-XT PCB

|

Units

|

Test

Conditions

|

Test Method

|

|

Electrical

Properties

|

|

Dielectric Constant

|

2.94

|

-

|

23˚C

@ 50% RH

|

10

GHz

|

IPC

TM-650 2.5.5.5

|

|

Dissipation Factor

|

0.0010

|

-

|

23˚C

@ 50% RH

|

10

GHz

|

IPC

TM-650 2.5.5.5

|

|

Dielectric Constant (design)

|

2.93

|

-

|

C-24/23/50

|

10

GHz

|

Microstrip

Differential Phase Length

|

|

Thermal Coefficient of Dielectric Constant

|

-8

|

ppm/˚C

|

-50°C

to 150°C

|

10

GHz

|

IPC

TM-650 2.5.5.5

|

|

Volume Resistivity

|

4.25x10⁸

|

Mohm-cm

|

C-96/35/90

|

-

|

IPC

TM-650 2.5.17.1

|

|

Surface Resistivity

|

2.49x10⁸

|

Mohm

|

C-96/35/90

|

-

|

IPC

TM-650 2.5.17.1

|

|

Electrical Strength (dielectric strength)

|

1000

|

V/mil

|

-

|

-

|

IPC

TM-650 2.5.6.2

|

|

Dielectric Breakdown

|

58

|

kV

|

D-48/50

|

X/Y

direc- tion

|

IPC

TM-650 2.5.6

|

|

PIM (For antenna only)

|

-

|

dBc

|

-

|

50

ohm

0.060"

|

43dBm 1900 MHz

|

|

Thermal

Properties

|

|

Decomposition Temperature (Td)

|

539

|

˚C

|

2hrs

@ 105˚C

|

5%

Weight Loss

|

IPC

TM-650 2.3.40

|

|

Coefficient of Thermal Expansion - x

|

12.7

|

ppm/˚C

|

-

|

-55˚C

to 288˚C

|

IPC

TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - y

|

13.7

|

ppm/˚C

|

-

|

-55˚C

to 288˚C

|

IPC

TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - z

|

40.8

|

ppm/˚C

|

-

|

-55˚C

to 288˚C

|

IPC

TM-650 2.4.41

|

|

Thermal Conductivity

|

0.56

|

W/(m.K)

|

-

|

z

direction

|

ASTM

D5470

|

|

Time to Delamination

|

>60

|

minutes

|

as-received

|

288˚C

|

IPC

TM-650 2.4.24.1

|

|

Mechanical

Properties

|

|

Copper Peel Strength after Thermal Stress

|

1.7

(9)

|

N/mm

(lbs/ in)

|

10s

@288˚C

|

35

μm foil

|

IPC

TM-650 2.4.8

|

|

Flexural Strength (MD, CMD)

|

40.7,

40.0

(5.9, 5.8)

|

MPa

(ksi )

|

25˚C±3˚C

|

-

|

ASTM

D790

|

|

Tensile Strength (MD, CMD)

|

29.0,

25.5

(4.2, 3.7)

|

MPa

(ksi )

|

23C/50RH

|

-

|

ASTM

D638

|

|

Flex Modulus (MD. CMD)

|

3247,

3261

(471, 473)

|

MPa

(ksi )

|

25C±3C

|

-

|

ASTM

D790

|

|

Dimensional Stability (MD, CMD)

|

-0.37,

-0.67

|

mm/m

|

4

hr at 105˚C

|

-

|

IPC-TM-650

2.4.39a

|

|

Physical

Properties

|

|

Flammability

|

V-0

|

-

|

-

|

C48/23/50

& C168/70

|

UL

94

|

|

Moisture Absorption

|

0.02

|

%

|

E1/105+D24/23

|

-

|

IPC

TM-650 2.6.2.1

|

|

Density

|

2.17

|

g/cm³

|

C-24/23/50

|

-

|

ASTM

D792

|

|

Specifc Heat Capacity

|

0.61

|

J/g˚K

|

2

hours at 105˚C

|

-

|

ASTM

E2716

|

|

NASA Outgassing

|

0.02

/ 0.00

|

%

|

|

TML/CVCM

|

ASTM

E595

|

BICHENG PCB WORKSHOP:

BICHENG PCB EQUIPMENT:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com