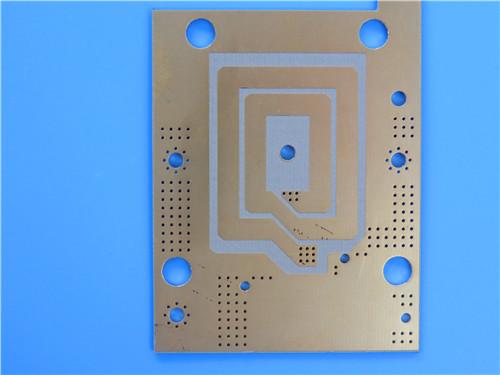

RogersTC600 PCB 2-layer 30mil0.762mm ENEPIG Green Solder Mask White Silkscreen

Designed for demanding RF, microwave, and power electronics scenarios, the TC600 2-layer 30mil ENEPIG PCB stands out as a game-changing substrate that merges Rogers’premium TC600 laminates with precision manufacturing. Engineered to deliver exceptional thermal conductivity, low dielectric loss, and structural stability, this Rogers RF PCB 30mil redefines reliability and efficiency for critical applications—from avionics to portable antennas. Below is a comprehensive breakdown of its specifications, performance, and value proposition.

PCB Construction Details

Precision-engineered manufacturing parameters ensure consistent performance, compatibility with standard assembly processes, and long-term durability:

|

Parameter

|

Specification

|

|

Base Material

|

TC600 (Rogers PTFE-ceramic composite)

|

|

Layer Count

|

Double sided

|

|

Board Dimensions

|

112mm x 60mm (1PCS) ± 0.15mm

|

|

Minimum Trace/Space

|

5/5 mils

|

|

Minimum Hole Size

|

0.3mm

|

|

Blind Vias

|

None

|

|

Finished Board Thickness

|

0.8mm

|

|

Finished Cu Weight (Outer Layers)

|

1oz (1.4 mils)

|

|

Via Plating Thickness

|

20 μm

|

|

Surface Finish

|

Electroless Nickel Electroless Palladium and Immersion Gold (ENEPIG)

|

|

Top Silkscreen

|

White

|

|

Bottom Silkscreen

|

No

|

|

Top Solder Mask

|

Green

|

|

Bottom Solder Mask

|

No

|

|

Quality Control

|

100% Electrical test prior to shipment

|

PCB Stackup

Strategically layered structure maximizes thermal conductivity and signal integrity, leveraging RogersTC600’s core strengths:

|

Layer

|

Material/Composition

|

Thickness

|

|

Top Copper Layer

|

Electrolytic Copper + Plating

|

18 μm (base) + 17 μm (plating)

|

|

Core Substrate

|

Rogers TC600 Laminate

|

0.762mm (30mil)

|

|

Bottom Copper Layer

|

Electrolytic Copper + Plating

|

18 μm (base) + 17 μm (plating)

|

PCB Statistics

Component and connectivity metrics reflect optimized design for high-performance applications:

|

Metric

|

Value

|

|

Total Components

|

32

|

|

Total Pads

|

146

|

|

Thru Hole Pads

|

94

|

|

Top SMT Pads

|

52

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

77

|

|

Nets

|

2

|

Application-Centric Performance Advantages

What sets this TC600 high frequency PCB apart is how its material and design translate to real-world results:

1) RF & Microwave Excellence: TC600’s stable Dk (6.15 at 1.8MHz–10GHz) and ultra-low dissipation factor (0.0017–0.0020) minimize insertion loss, boosting antenna gain and amplifier efficiency—critical for GPS, DAB satellite radio, and RFID readers.

2) Superior Thermal Management: 1.1W/mK thermal conductivity dissipates heat rapidly, eliminating hot spots in power amplifiers and avionics combiners, extending component lifespan by up to 30% compared to standard substrates.

3) Mechanical Reliability: Low CTE (9/9/35 ppm/°C) matches semiconductor components, reducing solder joint stress during temperature cycles (-40°C to 140°C)–ideal for harsh aerospace and industrial environments.

4) Assembly-Friendly Design: ENEPIG finish ensures consistent solder joints, while 5/5 mils trace/space and 0.3mm minimum hole size support high-precision assembly without compromising manufacturability.

Customer-Centric Benefits

This TC600 microwave PCB delivers tangible value by addressing key industry pain points:

1)Size Reduction: Higher thermal conductivity and optimized Dk enable compact PCB designs compared to lower-performance substrates.

2)Heat Management: Reduces transmission line loss and dissipates heat efficiently, extending component lifespan.

3)Enhanced Reliability: Low CTE mismatch, minimal moisture absorption, and 100% electrical testing ensure consistent performance in critical operations.

4)Simplified Processing: Compatible with standard manufacturing workflows while maintaining precision.

Ideal for Target Applications

This 30 mil TC600 PCB is purpose-built to excel in:

- Power Amplifiers, Filters and Couplers

- Microwave Combiner and Power Divider Boards in Avionics Applications

- Small Footprint Antennas

- Digital Audio Broadcasting (DAB) Antennas(Satellite Radio)

- GPS & Hand-held RFID Reader Antennas

For customized quotes, technical support, or sample requests, our global sales team is ready to assist. Partner with us to leverage this high-performance PCB for your critical applications.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com