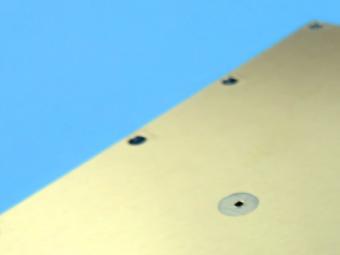

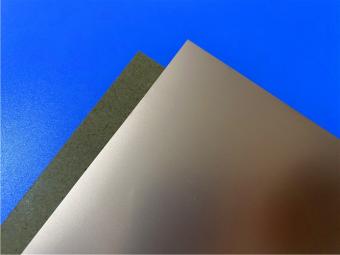

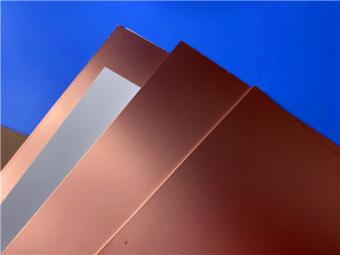

Taconic TLY-5 Avionics & Aerospace Grade Low DK2.2 DF0.0009 Base Material

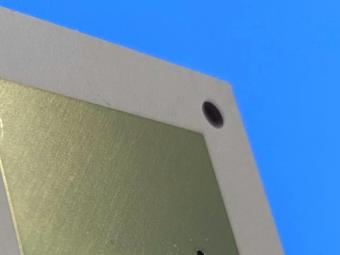

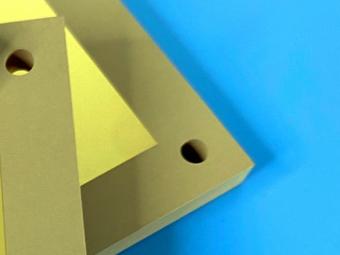

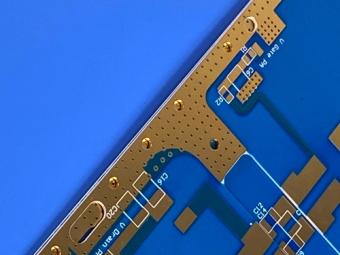

TLY-5 Copper clad laminates are produced using ultra-lightweight woven fiberglass, delivering notably higher dimensional stability than chopped fiber-reinforced PTFE composites. The woven matrix of Taconic TLY-5 laminate creates a mechanically robust laminate, ideal for high-volume manufacturing processes. Its low dissipation factor allows for reliable application in 77 GHz automotive radar systems, as well as other antennas operating at millimeter-wave frequencies.

Comparative OEM testing at 77 GHz between lightly reinforced TLY-5 CCL and its closest chopped fiber-reinforced competitor has demonstrated equivalent insertion losses and dielectric properties, enabling "drop-in" compatibility. A key advantage ofTLY-5 base material is its significantly higher manufacturing yield rate. The dielectric constant of TLY-5 PCB substrate ranges from 2.17 to 2.40, and for most thicknesses, it can be specified to any value within this range with a tolerance of±0.02. At 10 GHz, the dissipation factor is approximately 0.0009.

Typical applications include satellite communications, automotive radar, filters, couplers, avionics, and phased array antennas.

Key Advantages

-

Exceptional dimensional stability

-

Extremely low dissipation factor

-

Strong peel strength

-

Minimal moisture absorption

-

Consistent and uniform dielectric constant

-

Compatible with laser ablation processes

Typical Uses

-

Automotive radar systems

-

Satellite and cellular communication equipment

-

Power amplifiers

-

LNBs, LNAs, LNCs

-

Aerospace electronics

-

Ka, E, and W band applications

Key Properties

|

TLY TYPICAL VALUES

|

|

Property

|

Test Method

|

Unit

|

Value

|

|

DK at 10 GHz

|

IPC-650 2.5.5.5

|

|

2.2

|

|

Df at 10 GHz

|

IPC-650 2.5.5.5

|

|

0.0009

|

|

Moisture Absorption

|

IPC-650 2.6.2.1

|

%

|

0.02

|

|

Dielectric Breakdown

|

IPC-650 2.5.6

|

kV

|

>45

|

|

Dielectric Strength

|

ASTM D 149

|

V/mil

|

106,023

|

|

Volume Resistivity

|

IPC-650 2.5.17.1(after elevated temp.)

|

Mohms/cm

|

1010

|

|

Volume Resistivity

|

IPC-650 2.5.17.1(after humidity)

|

Mohms/cm

|

109

|

|

Surface Resistivity

|

IPC-650 2.5.17.1(after elevated temp.)

|

Mohms

|

108

|

|

Surface Resistivity

|

IPC-650 2.5.17.1(after humidity)

|

Mohms

|

108

|

|

Flex Strength(MD)

|

IPC-650 2.4.4

|

N/mm2

|

96.91

|

|

Flex Strength(CD)

|

IPC-650 2.4.4

|

N/mm2

|

89.32

|

|

Peel Stength(½ oz.ed copper)

|

IPC-650 2.4.8

|

N/mm

|

1.96

|

|

Peel Stength(1 oz.CL1 copper)

|

IPC-650 2.4.8

|

N/mm

|

2.86

|

|

Peel Stength(1 oz..CV1 copper)

|

IPC-650 2.4.8

|

N/mm

|

3.04

|

|

Peel Stength

|

IPC-650 2.4.8(after elevated temp.)

|

N/mm

|

2.32

|

|

Young's Modulus(MD)

|

ASTM D 3039/IPC-650 2.4.19

|

N/mm2

|

9.65 x 103

|

|

Poisson's Ratio(MD)

|

ASTM D 3039/IPC-650 2.4.19

|

|

0.21

|

|

Thermal Conductivity

|

ASTM F 433

|

W/M*K

|

0.22

|

|

Dimensional Stability(MD,10mil)

|

IPC-650 2.4.39(avg.after bake&thermal stress)

|

|

-0.038

|

|

Dimensional Stability(CD,10mil)

|

IPC-650 2.4.39(avg.after bake&thermal stress)

|

|

-0.031

|

|

Density(Specific Gravity)

|

ASTM D 792

|

g/cm3

|

2.19

|

|

CTE(X axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

26

|

|

CTE(Y axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

15

|

|

CTE(Z axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

217

|

|

NASA Outgassing(% TML)

|

|

|

0.01

|

|

NASA Outgassing(% CVCM)

|

|

|

0.01

|

|

NASA Outgassing(% WVR)

|

|

|

0.00

|

|

UL-94 Flammability Rating

|

UL-94

|

|

V-0

|

Typical Thicknesses

|

Inch

|

mm

|

Inch

|

mm

|

|

0.0035

|

0.09

|

0.02

|

0.51

|

|

0.005

|

0.13

|

0.03

|

0.76

|

|

0.0075

|

0.19

|

0.031

|

0.79

|

|

0.01

|

0.25

|

0.06

|

1.52

|

Available Sheet Sizes

|

Inch

|

mm

|

Inch

|

mm

|

|

12 x 18

|

305 x 457

|

16 x 36

|

406 x 914

|

|

16 x 18

|

406 x 457

|

24 x 36

|

610 x 914

|

|

18 x 24

|

457 x 610

|

18 x 48

|

457 x 1220

|

Notes

All test data provided are typical values and not intended to be specification values. For critical specification tolerance reviews, please contact an AGC representative directly.

TaconicTLY-5 can be manufactured in increments of 0.00” (0.125mm).

Standard panel size is 18” x 24” (457 mm x 610 mm).

For availability of additional thicknesses, alternative sizes, or other cladding types, please contact AGC.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com