IsoClad 917 Copper Clad laminates DK2.17 Rogers Substrate 0.0013 Dissipation Factor

1. Product Overview

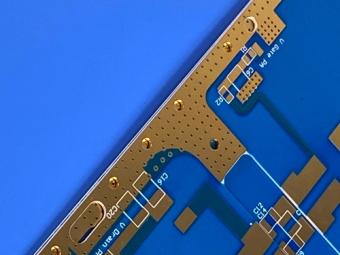

Rogers IsoClad 917 laminates are high-performance composites engineered with nonwoven fiberglass and PTFE, specifically formulated for use as printed circuit board (PCB) substrates. The nonwoven reinforcing structure delivers exceptional flexibility, making these laminates ideal for applications requiring the final circuit to be bent or shaped—conformal ("wrap-around") antennas are a prime example of such use cases.

Leveraging longer random fibers and a proprietary manufacturing process, IsoClad 917 Copper Clad laminates outperforms competing nonwoven fiberglass/PTFE laminates with similar dielectric constants. It offers superior dimensional stability and more consistent dielectric constant performance. A key advantage of IsoClad 917 substrates (with a dielectric constant Er of 2.17 or 2.20) lies in its low fiberglass-to-PTFE ratio, which enables it to achieve the lowest dielectric constant and dissipation factor among PTFE-fiberglass composite materials.

2. Core Features

-

Reinforced with nonwoven fiberglass

-

Low dielectric constant (Er=2.17, 2.20)

-

Exceptionally low loss characteristics

3. Key Benefits

-

Less rigid than woven fiberglass-based laminates, facilitating bending and shaping

-

High isotropy across X, Y, and Z axes, ensuring uniform performance in all directions

4. Typical Applications

-

Conformal antennas

-

Stripline and microstrip circuits

-

Missile guidance systems

-

Radar and electronic warfare systems

5. Technical Specifications Table

|

Property

|

Test Method

|

Test Condition

|

IsoClad 917 Value

|

|

Dielectric Constant @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

2.17, 2.20

|

|

Dissipation Factor @ 10 GHz

|

IPC TM-650 2.5.5.5

|

C23/50

|

0.0013

|

|

Thermal Coefficient of Er (ppm/°C)

|

IPC TM-650 2.5.5.5 Adapted

|

-10°C to +140°C

|

-157

|

|

Peel Strength (lbs. per inch)

|

IPC TM-650 2.4.8

|

After Thermal

|

10

|

|

Volume Resistivity (MΩ-cm)

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

1.5 x 10¹⁰

|

|

Surface Resistivity (MΩ)

|

IPC TM-650 2.5.17.1

|

C96/35/90

|

1.0 x 10⁹

|

|

Arc Resistance (seconds)

|

ASTM D-495

|

D48/50

|

>180

|

|

Tensile Modulus (kpsi)

|

ASTM D-638

|

A, 23°C

|

133, 120

|

|

Tensile Strength (kpsi)

|

ASTM D-882

|

A, 23°C

|

4.3, 3.8

|

|

Compressive Modulus (kpsi)

|

ASTM D-695

|

A, 23°C

|

182

|

|

Flexural Modulus (kpsi)

|

ASTM D-790

|

A, 23°C

|

213

|

|

Dielectric Breakdown (kv)

|

ASTM D-149

|

D48/50

|

>45

|

|

Density (g/cm³)

|

ASTM D-792 Method A

|

A, 23°C

|

2.23

|

|

Water Absorption (%)

|

MIL-S-13949H 3.7.7 / IPC TM-650 2.6.2.2

|

E1/105 + D24/23

|

0.04

|

|

Coefficient of Thermal Expansion (ppm/°C) - X Axis

|

IPC TM-650 2.4.24 (Mettler 3000 Thermomechanical Analyzer)

|

0°C to 100°C

|

46

|

|

Coefficient of Thermal Expansion (ppm/°C) - Y Axis

|

IPC TM-650 2.4.24 (Mettler 3000 Thermomechanical Analyzer)

|

0°C to 100°C

|

47

|

|

Coefficient of Thermal Expansion (ppm/°C) - Z Axis

|

IPC TM-650 2.4.24 (Mettler 3000 Thermomechanical Analyzer)

|

0°C to 100°C

|

236

|

|

Thermal Conductivity (W/mK)

|

ASTM E-1225

|

100°C

|

0.263

|

|

Outgassing - Total Mass Loss (%)

|

-

|

125°C, ≤10⁻⁶ torr

|

0.02

|

|

Outgassing - Collected Volatile Condensable Material (%)

|

-

|

125°C, ≤10⁻⁶ torr

|

0

|

|

Outgassing - Water Vapor Regain (%)

|

-

|

125°C, ≤10⁻⁶ torr

|

0.02

|

|

Outgassing - Visible Condensate

|

-

|

125°C, ≤10⁻⁶ torr

|

NO

|

|

Flammability

|

UL 94 Vertical Burn / IPC TM-650 2.3.10

|

C48/23/50, E24/125

|

Meets UL94-V0 requirements

|

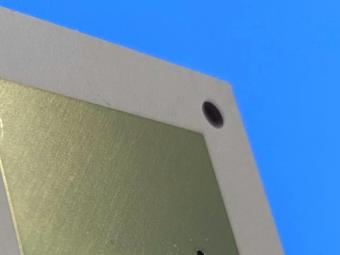

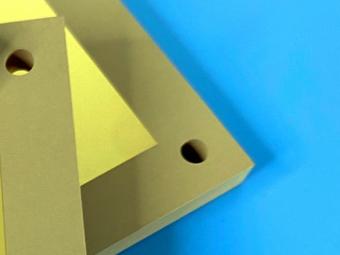

6. Standard Product Specifications

6.1 Standard Thicknesses

|

Thickness (Imperial)

|

Thickness (Metric)

|

Tolerance

|

|

0.031"

|

0.79mm

|

±0.0020"

|

|

0.062"

|

1.57mm

|

±0.0040"

|

Non-standard Thickness Option: Available from 0.005" to 0.195" in 0.005" increments.

6.2 Standard Panel Sizes

|

Cladding Type

|

Thickness (Imperial)

|

Thickness (Metric)

|

Configuration

|

|

Electrodeposited Copper Foil

|

0.5 oz.

|

18μm

|

HH/HH

|

|

Electrodeposited Copper Foil

|

1 oz.

|

35μm

|

HH/HH

|

Custom Panel Sizes: Available upon request.

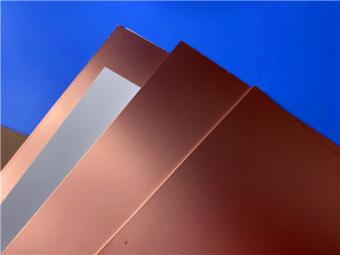

6.3 Standard Claddings

|

Panel Size (Imperial)

|

Panel Size (Metric)

|

|

12" × 18"

|

305mm × 457mm

|

|

24" × 18"

|

610mm × 457mm

|

Specialty Claddings: Heavy metal, resistive foil, and unclad options are available. Contact our Customer Service or Sales Engineering team for custom configurations.

7. Performance Graphs

7.1 Dielectric Constant vs. Frequency

X-axis: Frequency (GHz), range: 0-30 GHz

Y-axis: Percentage Change in Dielectric Constant

Key Characteristic: Exceptional dielectric constant stability across the frequency spectrum, simplifying design scalability across the EM range.

7.2 Dissipation Factor vs. Frequency

X-axis: Frequency (GHz), range: 0-30 GHz

Y-axis: Dissipation Factor, range: 0-0.0040

Key Characteristic: Ultra-low and stable dissipation factor across frequencies, ensuring reliable signal integrity for high-frequency applications.

Disclaimer: This data sheet is provided to assist with PCB design using IsoClad 917 high frequency laminates. It does not create any express or implied warranties, including merchantability or fitness for a specific purpose. Customers should verify the suitability of the material for their specific application.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com