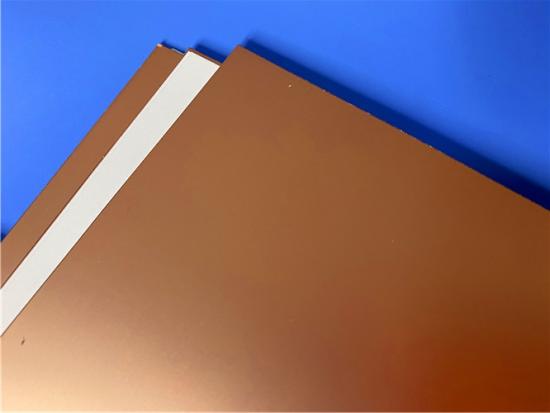

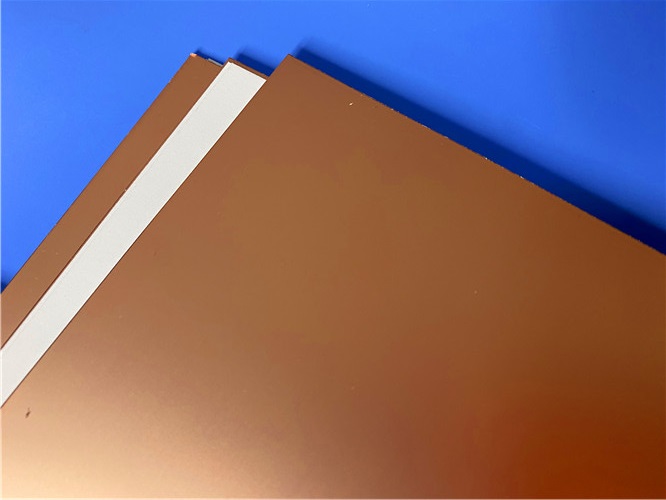

Taconic TLY-5Z Low DK2.2 Low Z-Axis Expansion Low Density Laminates

Overview

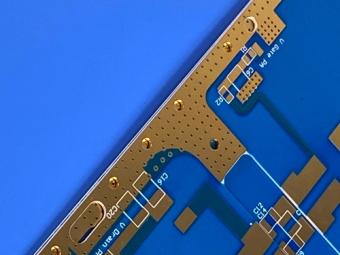

TLY-5Z laminate is an advanced glass-reinforced PTFE composite laminate designed for applications requiring low weight, dimensional stability, and reliable electrical performance. Its unique glass-filled structure provides superior thermal and mechanical properties compared to traditional PTFE-rich substrates, making it an ideal choice for demanding RF and aerospace applications.

Key Advantages

-

Low Z‑Axis CTE–Enhances plated through-hole reliability under thermal cycling.

-

Lightweight–Density of only 1.92 g/cm³, ideal for weight-sensitive designs.

-

Excellent Cost‑Performance Ratio–More economical than standard high‑PTFE laminates.

-

High Peel Strength–Ensures strong copper adhesion.

-

Compatible with Ultra‑Flat Copper Foils–Supports use with ULP (Ultra Low Profile) copper.

-

Superior Thermal Stability–Reduced drilling defects and improved multilayer reliability.

Typical Applications

-

Aerospace systems and components

-

Lightweight antennas for aviation

-

RF passive components and microwave circuits

-

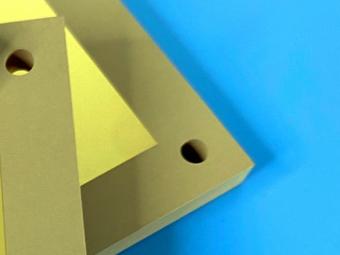

Substrate Integrated Waveguide (SIW) designs

-

High‑density multilayer stripline boards

Product Description

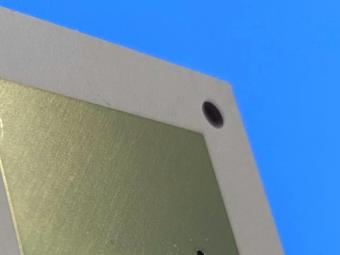

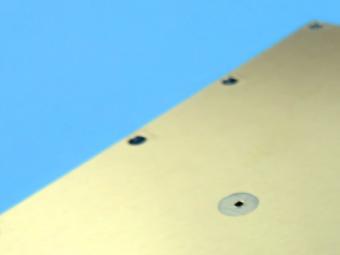

TLY-5Z copper clad laminates incorporate woven fiberglass reinforcement within a PTFE matrix, delivering a dimensionally stable composite that maintains performance under thermal stress. The material exhibits approximately half the Z‑axis expansion of conventional PTFE‑rich substrates, significantly reducing the risk of plated‑through‑hole cracking during thermal cycling. This makes TLY-5Z substrate suitable for complex, high‑layer‑count designs where thermal reliability is critical.

In addition to its mechanical benefits, TLY-5Z DK2.2 laminate offers excellent passive intermodulation distortion (PIMD) performance, meeting the stringent requirements of modern communication systems (typically below–153 dBc across common cellular bands). The laminate also supports efficient ground‑stitching and high‑density via patterns, enabling advanced RF architectures such as SIW.

PIMD Performance

TLY-5Z Taconic substrate demonstrates consistent PIMD characteristics even after repeated thermal cycling, ensuring long‑term signal integrity in plated‑through‑hole designs. Test data referenced in the original document confirms compliance with industry PIM standards.

Technical Properties of TLY-5Z

|

TLY-5Z Typical Values

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

Dk @ 1.9 GHz

|

IPC-650 2.5.5.5.1 Mod.

|

|

2.20+/- 0.04

|

|

2.20+/- 0.04

|

|

Df @ 1.9 GHz

|

IPC-650 2.5.5.5.1 Mod.

|

|

0.001

|

|

0.001

|

|

Df @ 10 GHz

|

IPC-650 2.5.5.5.1 Mod.

|

|

0.0015

|

|

0.0015

|

|

Tc(D)K (-55 ~150°C)

|

IPC-650 2.5.5.6 Mod.

|

ppm/°C

|

-72

|

ppm/°C

|

-72

|

|

Dielectric Breakdown Voltage

|

IPC-650 2.5.6

|

kV

|

45

|

kV

|

45

|

|

Dielectric Strength

|

IPC-650 2.5.6.2

|

V/mil

|

770

|

V/mm

|

30,315

|

|

Moisture Absorption

|

IPC-650 2.6.2.1

|

%

|

0.03

|

%

|

0.03

|

|

Peel Strength (1 oz. copper)

|

IPC-650 2.4.8

|

lbs./inch

|

7

|

N/mm

|

1.3

|

|

Volume Resistivity

|

IPC-650 2.5.17.1

|

Mohms/cm

|

10^9

|

Mohms/cm

|

10^9

|

|

Surface Resistivity

|

IPC-650 2.5.17.1

|

Mohms

|

10^8

|

Mohms

|

10^8

|

|

Tensile Strength (MD)

|

IPC-650 2.4.18.3

|

psi

|

9137

|

N/mm2

|

63

|

|

Tensile Strength (CD)

|

IPC-650 2.4.18.3

|

psi

|

9572

|

N/mm2

|

66

|

|

Tensile Modulus (MD)

|

IPC-650 2.4.18.3

|

psi

|

182,748

|

N/mm2

|

1260

|

|

Tensile Modulus (CD)

|

IPC-650 2.4.18.3

|

psi

|

165,344

|

N/mm2

|

1140

|

|

Elongation (MD)

|

IPC-650 2.4.18.3

|

%

|

6

|

%

|

6

|

|

Elongation (CD)

|

IPC-650 2.4.18.3

|

%

|

6.9

|

%

|

6.9

|

|

Flex Strength (MD)

|

ASTM D790

|

psi

|

10,300

|

N/mm2

|

71

|

|

Flex Strength (CD)

|

ASTM D790

|

psi

|

11,600

|

N/mm2

|

80

|

|

Flex Modulus (MD)

|

ASTM D790

|

psi

|

377,100

|

N/mm2

|

2600

|

|

Flex Modulus (CD)

|

ASTM D790

|

psi

|

432,213

|

N/mm2

|

2980

|

|

Dimensional Stability (MD)

|

IPC-650 2.4.39(Bake)

|

% (10 mil)

|

-0.05

|

% (30 mil)

|

-0.05

|

|

Dimensional Stability (CD)

|

IPC-650 2.4.39(Bake)

|

% (10 mil)

|

-0.17

|

% (30 mil)

|

-0.11

|

|

Dimensional Stability (MD)

|

IPC-650 2.4.39(Stress)

|

% (10 mil)

|

-0.07

|

% (30 mil)

|

-0.07

|

|

Dimensional Stability (CD)

|

IPC-650 2.4.39(Stress)

|

% (10 mil)

|

-0.22

|

% (30 mil)

|

-0.14

|

|

Density (Specific Gravity)

|

IPC-650 2.3.5

|

g/cm3

|

1.92

|

g/cm3

|

1.92

|

|

Specific Heat

|

IPC-650 2.4.50

|

J/g°C

|

0.95

|

J/g°C

|

0.95

|

|

Thermal Conductivity

|

IPC-650 2.4.50

|

W/M*K

|

0.2

|

W/M*K

|

0.2

|

|

CTE (x-y) (50 - 150°C)

|

IPC-650 2.4.41

|

ppm/ºC

|

30-40

|

ppm/ºC

|

30-40

|

|

CTE (z) (50 - 150°C)

|

IPC-650 2.4.41

|

ppm/ºC

|

130

|

ppm/ºC

|

130

|

|

Hardness

|

ASTM D2240(Durometer)

|

-

|

68

|

-

|

68

|

|

UL-94 Flammability Rating

|

UL-94

|

|

V-0

|

|

V-0

|

Standard Thicknesses

|

Inches

|

mm

|

|

0.01

|

0.25

|

|

0.02

|

0.51

|

|

0.03

|

0.76

|

|

0.06

|

1.52

|

Thicknesses can be manufactured in increments of 0.0100”(0.25 mm).

Panel Sizes Available

|

Inches

|

mm

|

|

12 × 18

|

305 × 457

|

|

16 × 18

|

406 × 457

|

|

18 × 24

|

457 × 610

|

Standard panel size: 18” x 24” (457 mmx 610 mm). Other sizes and cladding options available upon request.

Note: All values are typical and not guaranteed as specification limits. For critical tolerances and custom requirements, please contact our technical support team.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com